Ag-doped modified manganese-based mullite oxidation catalyst and preparation and application thereof

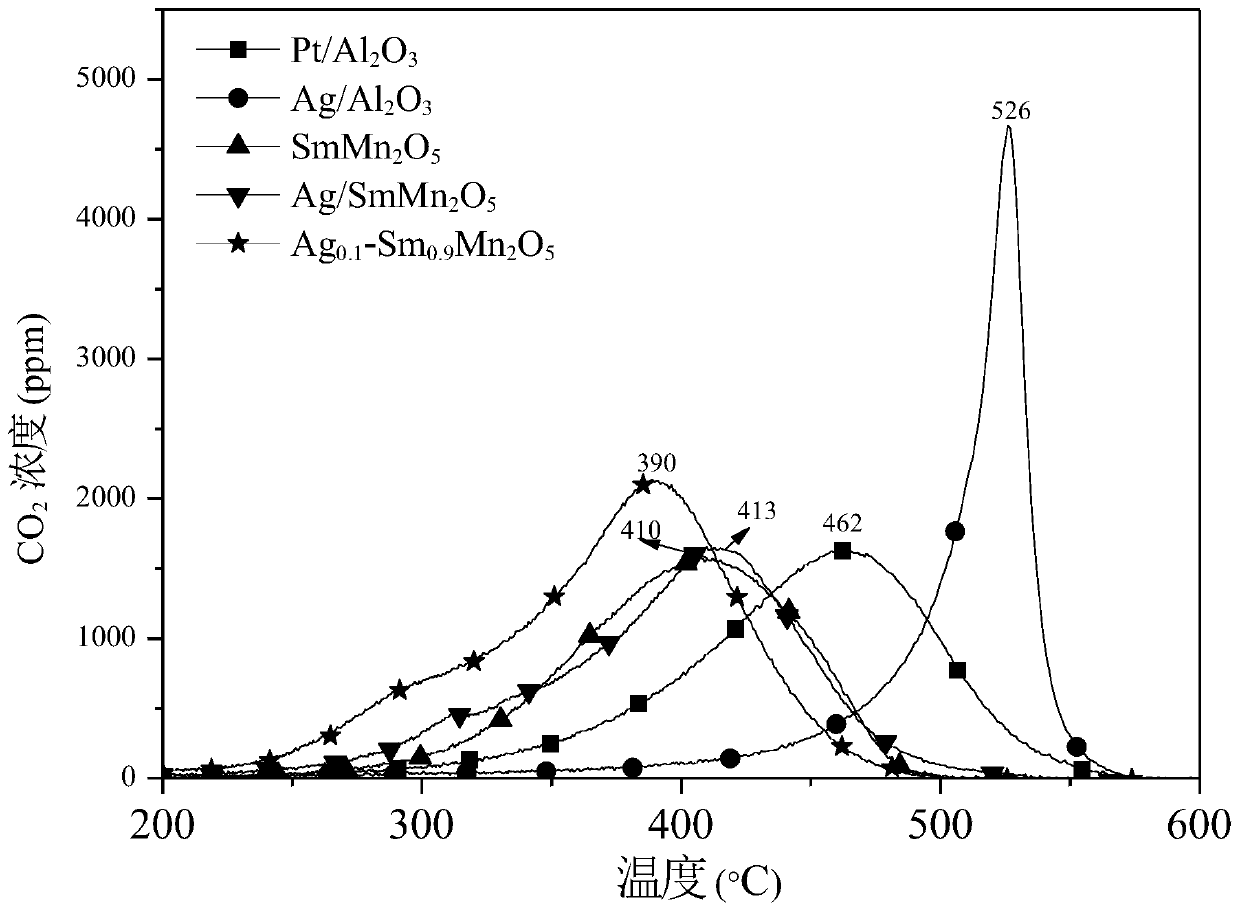

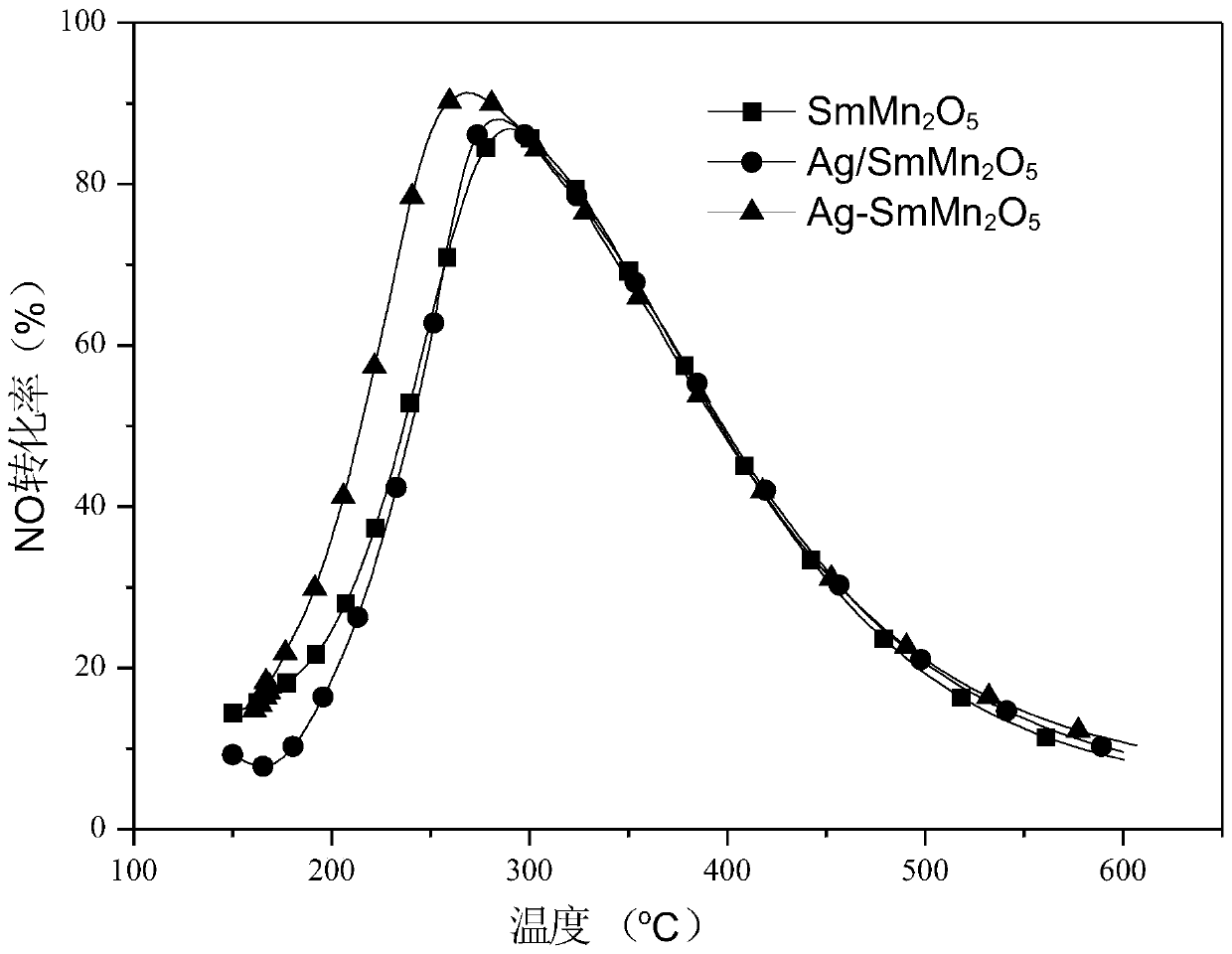

An oxidation catalyst, silver doping technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, heterogeneous catalyst chemical element, etc. Due to the large particle size and size of the nano-Ag particles, the effects of fast SCR reaction, high NO conversion rate, and simple preparation method are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

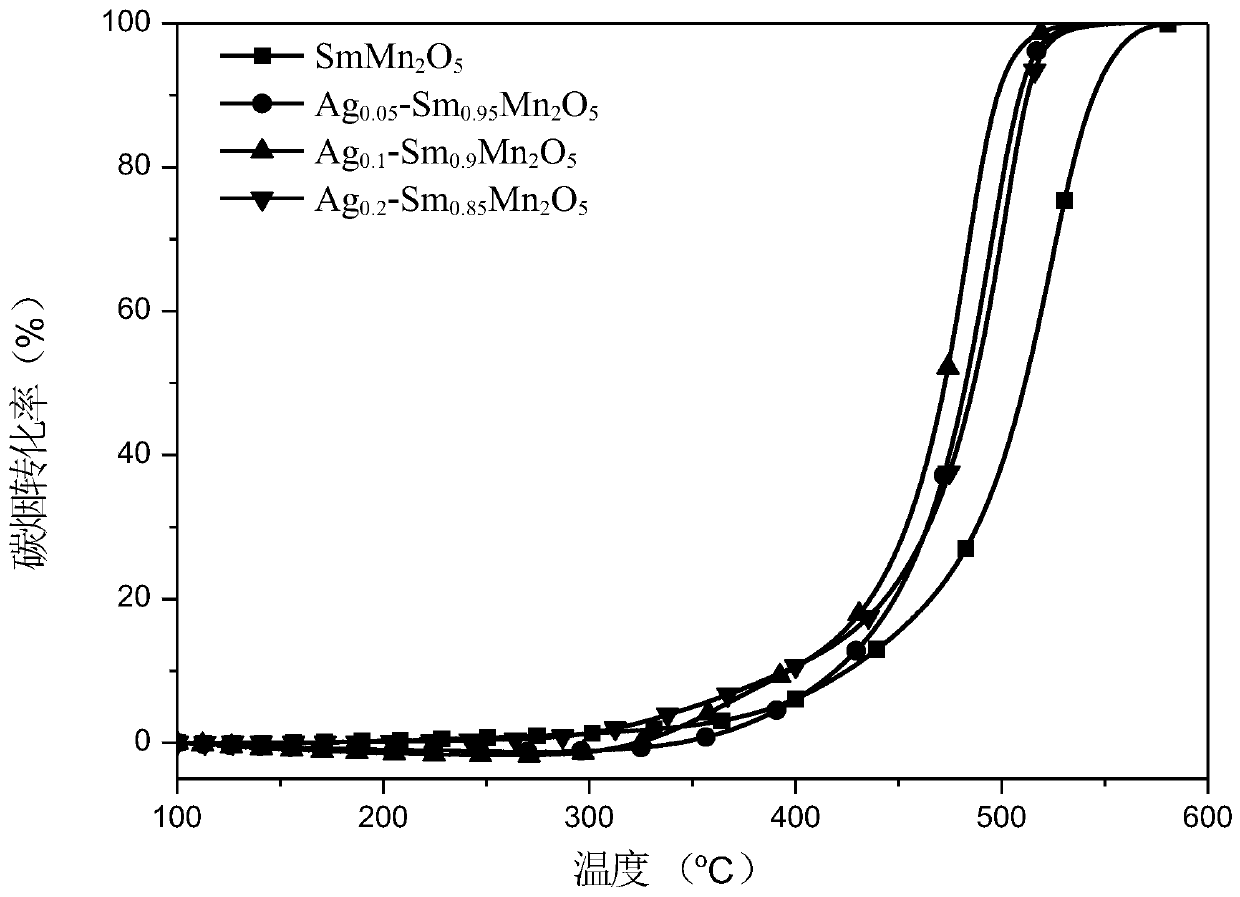

[0024] In this example, the in-situ complexation combustion method is used to prepare Ag-doped modified manganese-based mullite Ag 0.05 -Sm 0.95 mn 2 o 5 Catalyst, the complexing agent used is citric acid, the solvent is water, the molar ratio of citric acid and metal mixed salt (Ag source, Sm source and Mn source) is 1.1:1, and the roasting condition is 800 ℃ roasting in muffle furnace 5 hours.

[0025] The specific process is as follows: Weigh 0.7493g samarium nitrate, 0.01507g silver nitrate, 1.2703g manganese nitrate, dissolve in 100mL distilled water, 1.1252g citric acid, after stirring and dissolving, heat up to 80°C until the reaction is complete, collect the obtained powder, place Dry it in an oven at 110°C, bake it in a muffle furnace at 300°C for 1 hour, then raise the temperature to 800°C and continue roasting for 5 hours. The obtained catalyst is named Ag 0.05 -Sm 0.95 mn 2 o 5 , to test the catalytic NO and soot oxidation activity of the catalyst.

Embodiment 2

[0027] In this example, the in-situ complexation combustion method is used to prepare Ag-doped modified manganese-based mullite Ag 0.1 -Sm 0.9 mn 2o 5 Catalyst, the complexing agent used is citric acid, the solvent is water, the molar ratio of citric acid and metal mixed salt (Ag source, Sm source and Mn source) is 1.1:1, and the roasting condition is 800 ℃ roasting in muffle furnace 5 hours.

[0028] The specific process is as follows: Weigh 0.7144g samarium nitrate, 0.03034g silver nitrate, 1.2783g manganese nitrate, dissolve in 100mL distilled water, 1.1323g citric acid, after stirring and dissolving, heat up to 80°C until the reaction is complete, collect the obtained powder, place Dry it in an oven at 110°C, bake it in a muffle furnace at 300°C for 1 hour, then raise the temperature to 800°C and continue roasting for 5 hours. The obtained catalyst is named Ag 0.1 -Sm 0.9 mn 2 o 5 , to test the catalytic NO and soot oxidation activity of the catalyst.

Embodiment 3

[0030] In this example, the in-situ complexation combustion method is used to prepare Ag-doped modified manganese-based mullite Ag 0.2 -Sm 0.8 mn 2 o 5 Catalyst, the complexing agent used is citric acid, the solvent is water, the molar ratio of citric acid and metal mixed salt (Ag source, Sm source and Mn source) is 1.1:1, and the roasting condition is 800 ℃ roasting in muffle furnace 5 hours.

[0031] The specific process is as follows: Weigh 0.6431g samarium nitrate, 0.0615g silver nitrate, 1.2947g manganese nitrate, dissolve in 100mL distilled water, 1.1468g citric acid, after stirring and dissolving, heat up to 80°C until the reaction is complete, collect the obtained powder, place Dry it in an oven at 110°C, bake it in a muffle furnace at 300°C for 1 hour, then raise the temperature to 800°C and continue roasting for 5 hours. The obtained catalyst is named Ag 0.2 -Sm 0.8 mn 2 o 5 , to test the catalytic NO and soot oxidation activity of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com