Composite-carrier catalyst for ozone oxidation as well as preparation method and application of catalyst

A composite carrier and catalyst technology, which is applied in the field of composite carrier ozone catalyst and its preparation, can solve the problems of poor stability, high cost, and low efficiency of wastewater treatment, and achieve the effects of strong stability, reduced preparation cost, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

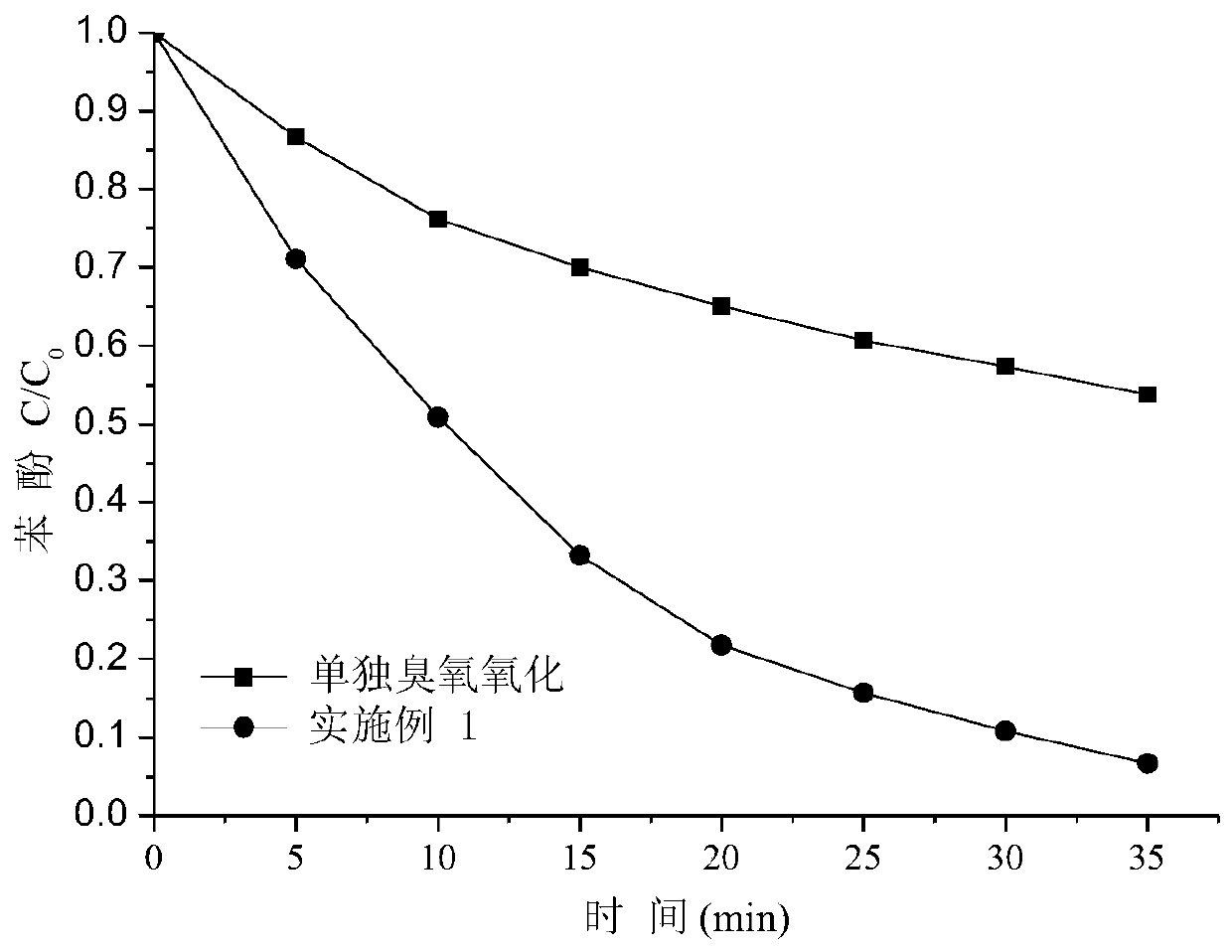

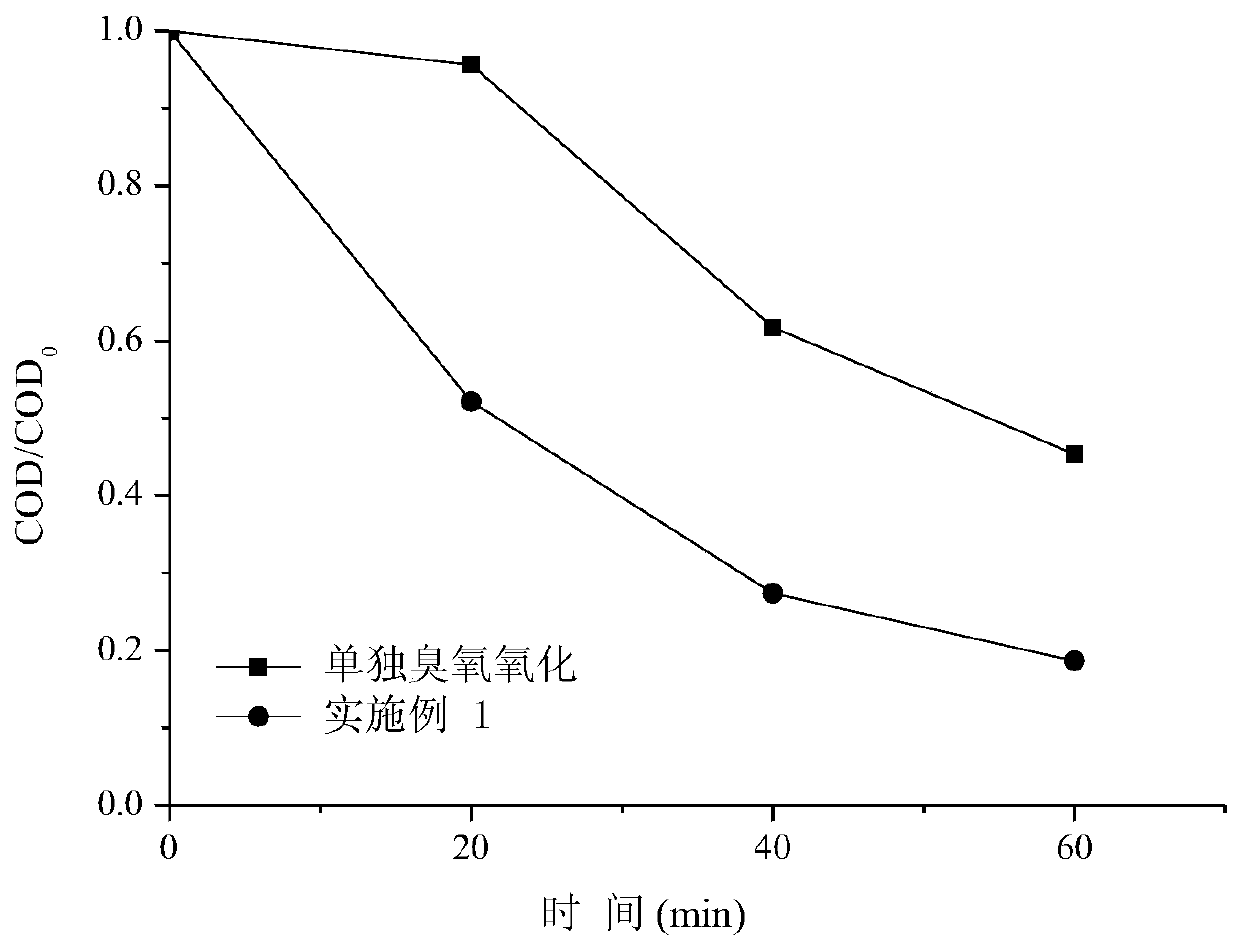

[0036] Example 1: Preparation of cotton straw-nano-alumina composite carrier ozone catalyst and its ozone oxidation performance

[0037] Prepare the cotton stalk-nano-alumina composite carrier ozone catalyst according to the following steps:

[0038] (1) Straw pretreatment: the agricultural waste cotton straw is crushed, cleaned, and surface impurities are removed, dried in an oven at a temperature of 100°C, ground to 80 mesh, and dried for later use;

[0039] (2) Straw activation: adding the powdered straw obtained in step (1) into a 0.1mol / L ammonia solution, dipping for 3 hours to complete the activation treatment of the straw, and drying the straw powder after the activation treatment in an oven at 100°C for 12 hours;

[0040] (3) Granulation and drying: 0.5g of straw powder prepared in step (2), 9.5g of alumina powder, 3g of sodium carboxymethyl cellulose, and deionized water were evenly mixed and ground to prepare carrier masterbatches. 2-8mm, dry in an oven at 100°C fo...

Embodiment 2

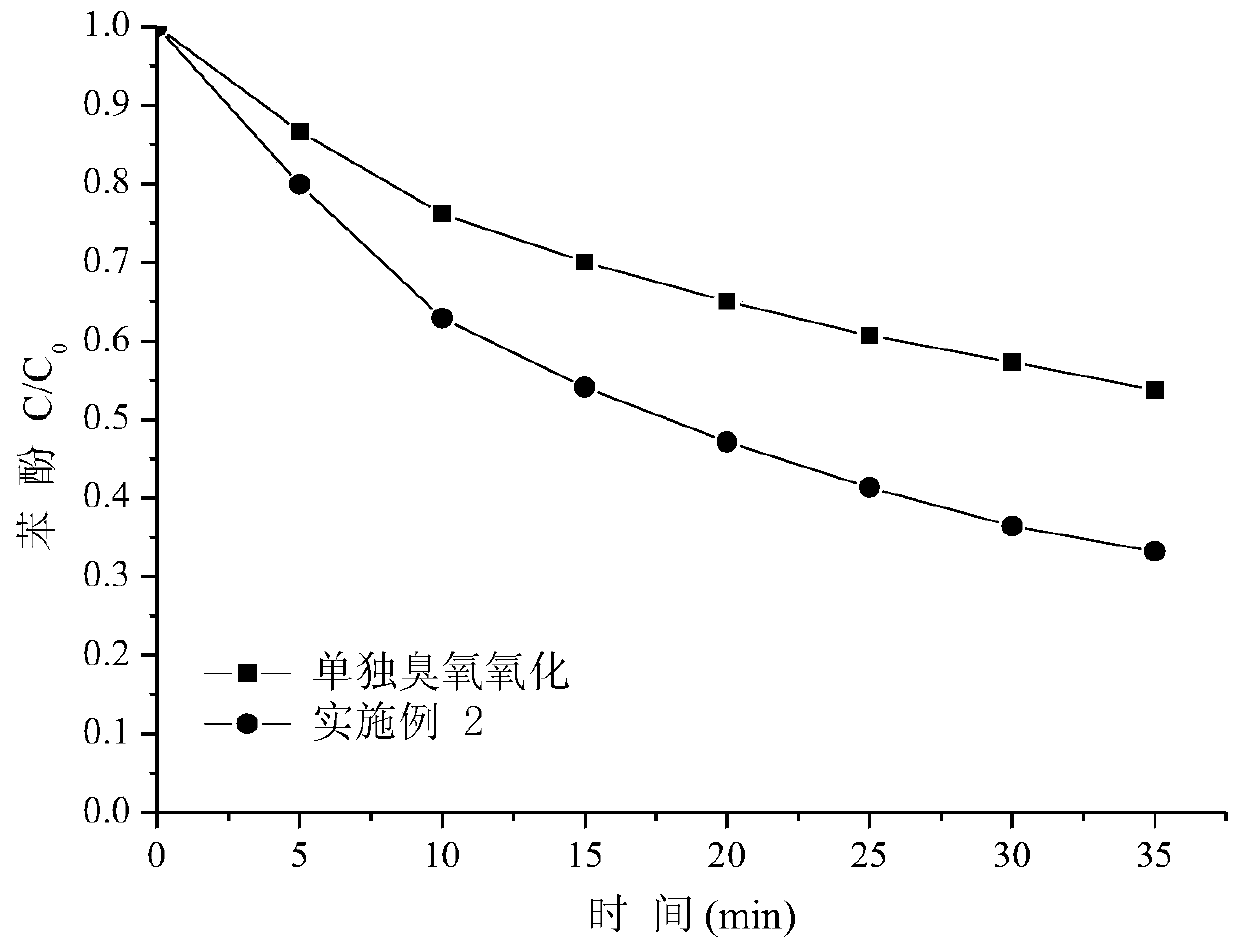

[0047] Example 2: Preparation of cotton straw-nano-alumina composite carrier ozone catalyst and its ozone oxidation performance

[0048] Prepare the cotton stalk-nano-alumina composite carrier ozone catalyst according to the following steps:

[0049] (1) Straw pretreatment: the agricultural waste cotton straw is crushed, cleaned, and surface impurities are removed, dried in an oven at a temperature of 105°C, ground to 80 mesh, and dried for later use;

[0050] (2) Straw activation: adding the powdered straw obtained in step (1) into a 0.2mol / L ammonia solution, dipping for 3 hours to complete the activation treatment of the straw, and drying the activated straw powder in an oven at 105°C for 12 hours;

[0051] (3) Granulation and drying: 0.2g of straw powder prepared in step (2), 9.8g of alumina powder, 2g of sodium carboxymethyl cellulose, and deionized water were evenly mixed and ground to prepare carrier masterbatches, particle size 2-8mm, dry in an oven at 105°C for 12 ho...

Embodiment 3

[0056] Example 3: Preparation of corn stalk-nano-alumina composite carrier ozone catalyst and its ozone oxidation performance

[0057] Prepare the corn stalk-nano-alumina composite carrier ozone catalyst according to the following steps:

[0058] (1) Straw pretreatment: the agricultural waste corn stalks were crushed, washed, and surface impurities were removed, dried in an oven at a temperature of 105°C for 12 hours, ground to 100 mesh, and dried for later use.

[0059] (2) Straw activation: adding the powdered straw obtained in step (1) into 0.3mol / L ammonia water, dipping for 4 hours, and completing the straw activation treatment; drying the activated straw powder in an oven at 105°C for 12 hours;

[0060] (3) Granulation and drying: 0.2g of straw powder prepared in step (2), 9.8g of alumina powder, 3g of methyl cellulose, and deionized water were uniformly mixed and ground to prepare carrier masterbatches with a particle size of 2 -8mm, dry in an oven at 105°C for 12 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com