Method for advanced reduction degradation of azo dye by using ultraviolet/magnesium process desulfurization slag

A magnesium desulfurization and azo dye technology, applied in the field of solid waste resource utilization, can solve the problems of high infrastructure investment and operation costs, and reduced desulfurization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method of using ultraviolet / magnesium desulfurization slag in this embodiment for advanced reduction and degradation of azo dyes is carried out according to the following steps:

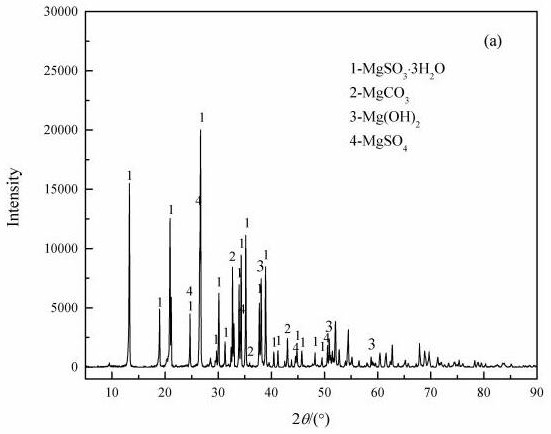

[0018] (1) Dry the waste (desulfurization residue) from the wet magnesium flue gas desulfurization system in stable operation at 80°C, grind it through an 80-mesh sieve, and take the powder under the sieve and bag it for use;

[0019] (2) Take 150 mL of methyl orange wastewater with a concentration of 200 mg / L in the reaction tank, add 0.9 g of pretreated desulfurization residue, and adjust the reaction pH of the solution to 3.5. Continue to stir, and irradiate the reaction solution with a 20W ultraviolet lamp for 3.0 h;

[0020] (3) Adjust the pH of the treated wastewater to 6.0, and after standing for a period of time, filter the water.

[0021] After treatment, the removal rate of methyl orange in wastewater can reach more than 85%.

Embodiment 2

[0023] A method of using ultraviolet / magnesium desulfurization slag in this embodiment for advanced reduction and degradation of azo dyes is carried out according to the following steps:

[0024] (1) Dry the waste (desulfurization residue) from the wet magnesium flue gas desulfurization system in stable operation at 80°C, grind it through an 80-mesh sieve, and take the powder under the sieve and bag it for use;

[0025] (2) Take 200 mL of methyl orange wastewater with a concentration of 100 mg / L in the reaction tank, add 0.8 g of pretreated desulfurization residue, and adjust the reaction pH of the solution to 3.0. Continue to stir, and irradiate the reaction solution with an 80W ultraviolet lamp for 2.0 h;

[0026] (3) Adjust the pH of the treated wastewater to 7.0, and after standing for a period of time, filter the water.

[0027] After treatment, the removal rate of methyl orange in wastewater can reach more than 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com