Method for preparing high-purity iron oxide by superconducting high-gradient magnetic separation converter dust removal

A technology of high-gradient magnetic separation and converter dust removal, which is applied in the fields of resources, energy conservation and environmental protection, can solve problems such as difficult to exceed and high operating costs, achieve good results, and achieve large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

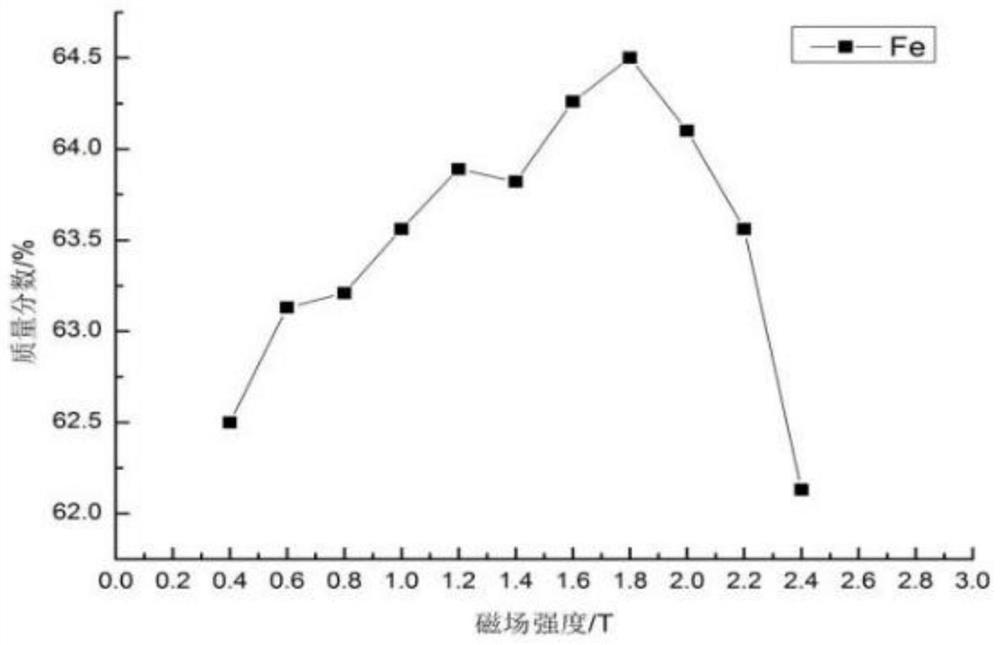

[0025] Under the conditions of mineral powder particle size -200 mesh, pulp concentration 15g / L, magnetic medium volume filling rate 8%, flow rate 500mL / min, and no dispersant, the iron content of magnetic separation products under different magnetic field intensities was studied.

[0026] Studies have shown that within a certain range, with the increase of magnetic field strength, the iron content of magnetic separation products also increases. When the magnetic field strength is 1.8T, the iron content of the magnetic separation product reaches the maximum value of 64.5%, and the magnetic field strength continues to increase, but the iron content of the magnetic separation product decreases instead, as figure 1 shown.

Embodiment 2

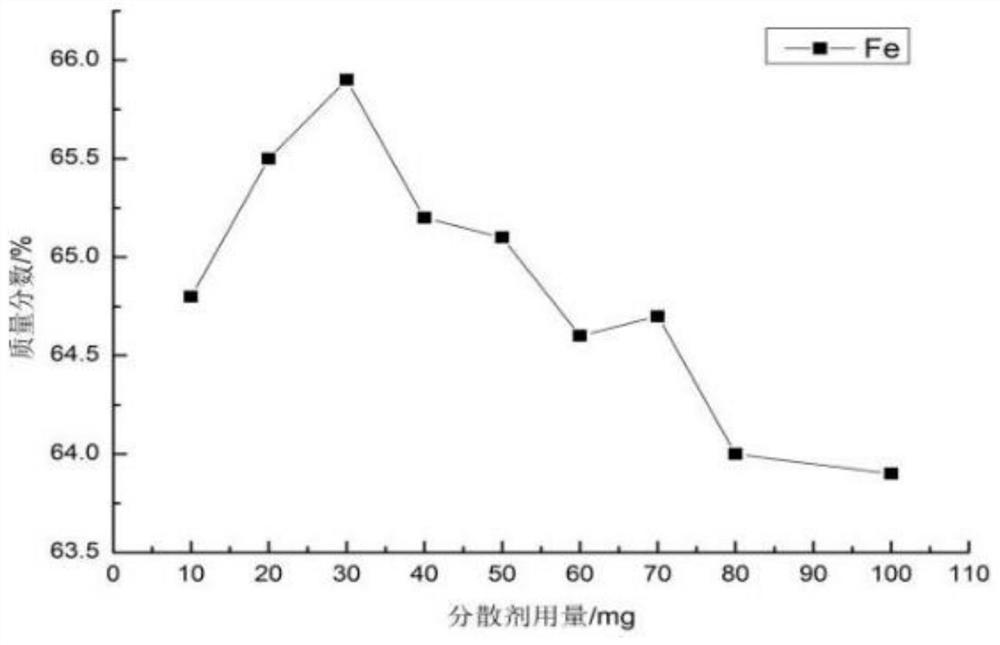

[0028] Under the conditions of mineral powder particle size -200 mesh, pulp concentration 15g / L, magnetic medium volume filling rate 8%, magnetic field strength 1.8T, and flow rate 500mL / min, the magnetic separation product iron under different dispersant sodium hexametaphosphate additions was studied. content.

[0029] Studies have shown that within a certain range, with the increase of the amount of dispersant, the iron content of magnetic separation products also increases. When the concentration of the dispersant used in the experiment was 30mg / L, the iron content of the magnetic separation product reached a maximum of 65.9%, and the concentration of the dispersant continued to increase, but the iron content of the magnetic separation product decreased instead, as figure 2 shown.

Embodiment 3

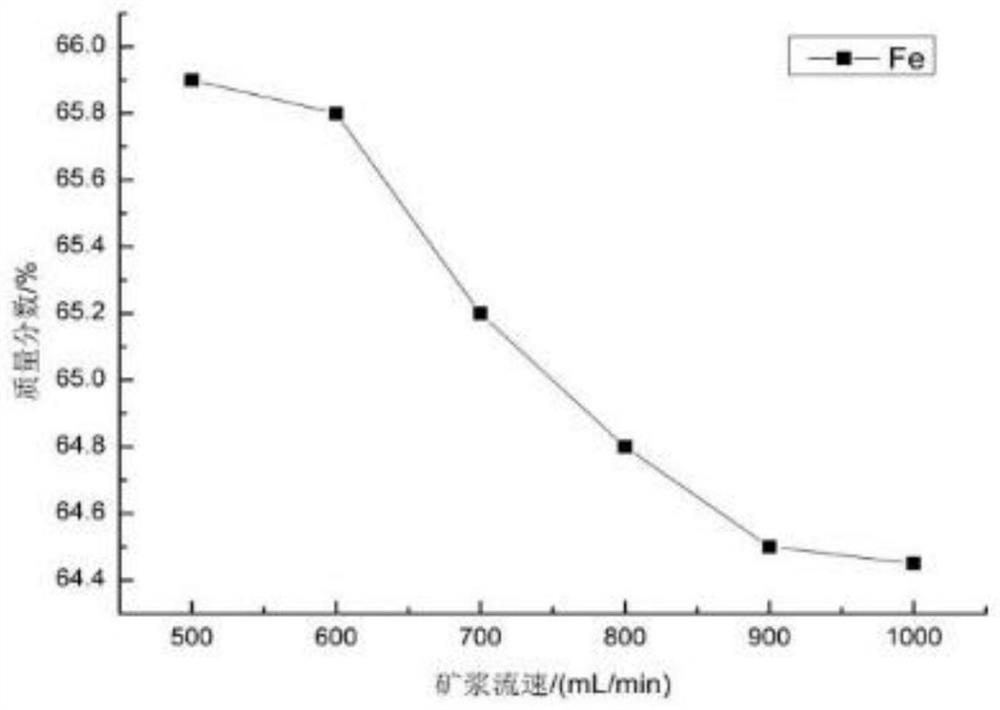

[0031] Under the conditions of mineral powder particle size -200 mesh, pulp concentration 15g / L, steel wool volume filling rate 8%, magnetic field strength 1.8T, and dispersant dosage 30mg / L, the iron content of magnetic separation products under different pulp flow rates was studied, such as image 3 shown.

[0032] Studies have shown that with the increase of slurry flow rate, the iron content of magnetic separation products has been decreasing.

[0033] The invention aims at the steelmaking converter dust removal ash with an iron content of 30-60%, and uses superconducting high gradient magnetic separation (SHGMS) technology to extract iron oxides, especially the extraction of weak magnetic oxides. The invention is a technological innovation. When the magnetic field strength is 1.2-3.0T, the volume filling rate of the magnetic separation medium is 8-30%, the particle size of the ore powder is -100 mesh (fine grinding is not required), the concentration of the ore pulp is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com