High-flame-retardancy fireproof door and window and manufacturing method thereof

A high flame retardant, door and window technology, applied in the field of doors and windows, can solve the problems of reducing the service life of wooden doors and windows, inability to fire and flame retardant, rot and mildew, so as to strengthen the anti-bacterial and anti-mildew effect, improve the anti-corrosion effect, and prevent the spread of fire. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

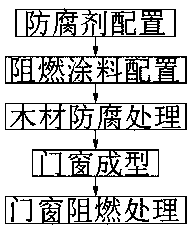

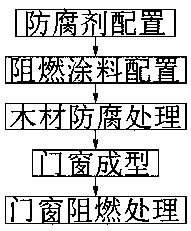

[0025] The production method of the high flame-retardant fire doors and windows comprises the following steps:

[0026] S1: Preservative configuration: put rosin emulsion, antioxidant, caprylic acid, sodium octaborate tetrahydrate, chelating agent, polyethylene glycol and absolute ethanol into the reaction kettle for stirring and mixing to prepare the preservative, the reaction kettle The stirring speed is 50-100 revolutions per minute, and the stirring and mixing time is 30 minutes, so that the rosin emulsion, antioxidant, caprylic acid, sodium octaborate tetrahydrate, chelating agent, polyethylene glycol and absolute ethanol are fully stirred together;

[0027] S2: Flame retardant coating configuration: put flame retardant, pentaerythritol, phosphate, epoxy resin, silica gel powder, refractory material, organic silicon quaternary ammonium salt and pure water into the reactor and mix them together to obtain a flame retardant coating. For coatings, the stirring speed of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com