Novel environmentally-friendly anticorrosive top coat

An environmental protection and topcoat technology, applied in anti-corrosion coatings, biocide-containing paints, anti-fouling/underwater coatings, etc. Anti-corrosion ability, the effect of improving anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

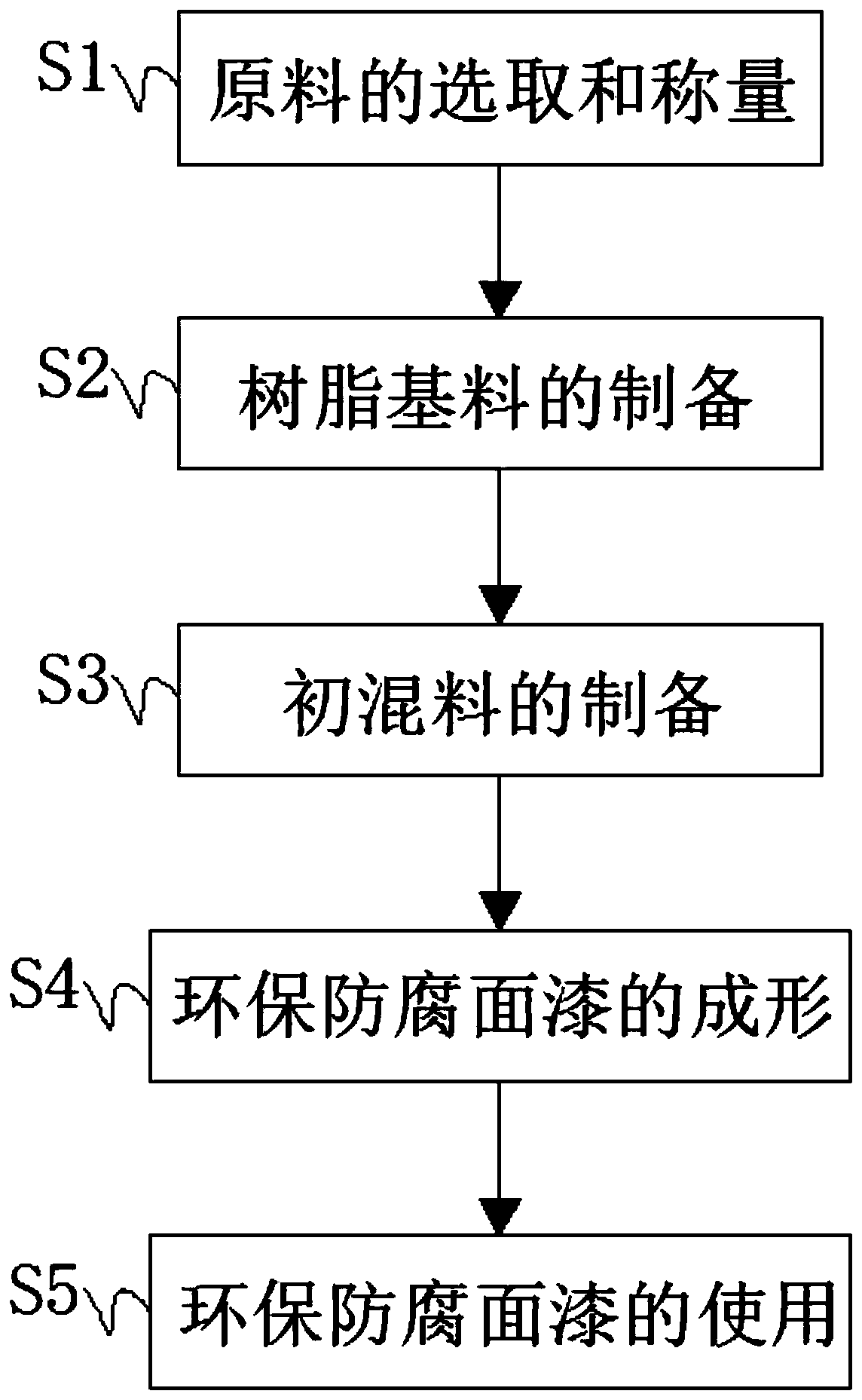

Image

Examples

Embodiment 1

[0026] S1. Selection and weighing of raw materials: First, take 65 parts of natural resin, 2 parts of anti-mold and fungicide, 0.7 part of silver chloride, 2 parts of curing agent, and 2 parts of zinc powder by weighing equipment. , 0.7 parts of sodium silicate, 7 parts of polyvinyl butyral resin, 0.7 part of crosslinking agent and 0.7 part of thickener, and store the weighed raw materials in storage tanks for subsequent use. Natural resins are rosin and amber Composition of resin, shellac, amaranth resin and copal resin, antifungal fungicide is the composition of 2-(trichloromethylthio)phthalimide and tetrachlorophthalonitrile, curing agent is phosphorus liquid;

[0027] S2. Preparation of resin base material: Pour the natural resin, polyvinyl butyral resin and crosslinking agent measured in step S1 into the mixing and stirring equipment in sequence, at a speed of 550r / min and a temperature of 29°C , mixed and stirred for 35 minutes, so as to complete the mixed modification ...

Embodiment 2

[0032] S1. Selection and weighing of raw materials: First, take 60 parts of natural resin, 3 parts of anti-mold and fungicide, 1 part of silver chloride, 3 parts of curing agent, and 3 parts of zinc powder by weighing equipment. , 1 part of sodium silicate, 5 parts of polyvinyl butyral resin, 1 part of crosslinking agent and 1 part of thickener, and store the weighed raw materials in a storage tank for future use. The natural resin is rosin, which prevents The fungicide is 2-(trichloromethylthio)phthalimide, and the curing agent is phosphating solution;

[0033] S2. Preparation of resin base material: Pour the natural resin, polyvinyl butyral resin and crosslinking agent measured in step S1 into the mixing and stirring equipment in sequence, at a speed of 500r / min and a temperature of 25°C , mixed and stirred for 30 minutes, so as to complete the mixed modification treatment of the resin base material;

[0034] S3, preparation of initial mixture: add the anti-mildew bacterici...

Embodiment 3

[0038] S1. Selection and weighing of raw materials: First, take 70 parts of natural resin, 1 part of anti-mold and fungicide, 0.5 part of silver chloride, 1 part of curing agent, and 1 part of zinc powder by weighing equipment. , 0.5 parts of sodium silicate, 10 parts of polyvinyl butyral resin, 0.5 part of crosslinking agent and 0.5 part of thickener, and store the weighed raw materials in storage tanks for subsequent use. The natural resin is copal resin , the mildew-proof fungicide is tetrachlorophthalonitrile, and the curing agent is phosphating solution;

[0039] S2. Preparation of resin base material: Pour the natural resin, polyvinyl butyral resin and crosslinking agent measured in step S1 into the mixing and stirring equipment in sequence, at a speed of 600r / min and a temperature of 32°C , mixed and stirred for 40 minutes, so as to complete the mixed modification treatment of the resin base material;

[0040] S3, preparation of initial mixture: add the anti-mildew bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com