Continuous flow dephosphorization nitrosation coupled anaerobic ammonia oxidation denitrification and dephosphorization SBR process

A technology of anaerobic ammonia oxidation and flow phosphorus removal, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve problems such as insufficient carbon source, achieve energy saving and high efficiency The effect of nitrogen and phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

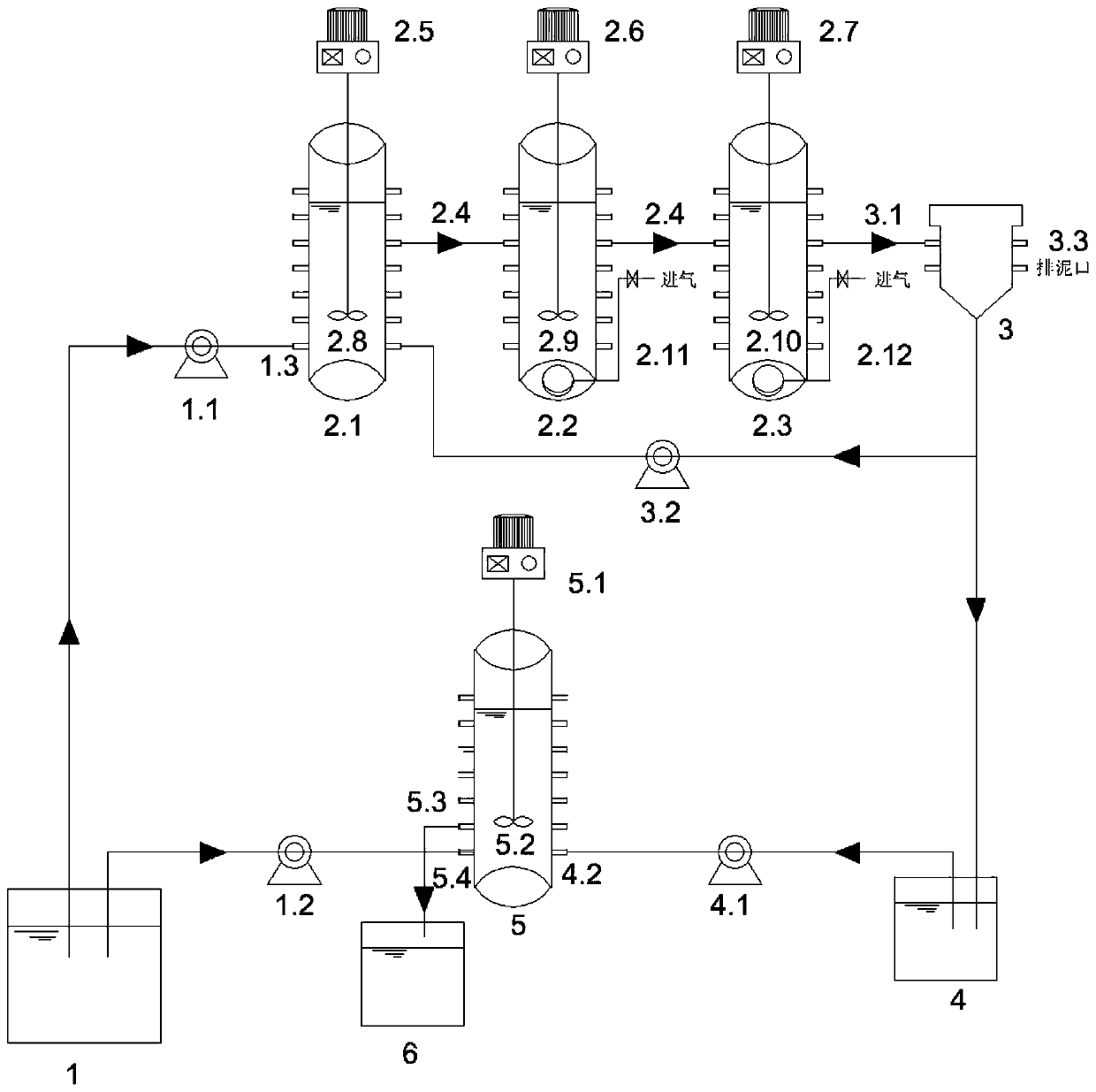

[0026] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the continuous-flow phosphorus removal and nitrosation coupled anammox denitrification and phosphorus removal SBR process is characterized in that it includes a domestic sewage raw water tank 1, a continuous flow phosphorus removal and nitrosation SBR reactor 2, a secondary sedimentation tank 3, and a regulating water tank 4. Anaerobic ammonium oxidation SBR reactor 5, effluent water tank 6; wherein the domestic sewage enters the continuous flow phosphorus removal nitrosation reactor from the domestic sewage raw water tank 1 respectively by the first water inlet peristaltic pump 1.1 and the second water inlet peristaltic pump 1.2 2 and ANAMMOX reactor 5. The continuous flow dephosphorization and nitrosation reactor 2 is composed of three SBR reactors with the same volume. According to the water flow direction, the first reactor 2.1, the second reactor 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap