Fischer-Tropsch slag wax treatment device and treatment process

A treatment device and treatment process technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, petroleum wax refining, etc., can solve the problems of low recovery rate of heavy wax and solvent, complicated operation process, etc., and achieve high degree of equipment centralization and process flow Simple and effective in reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

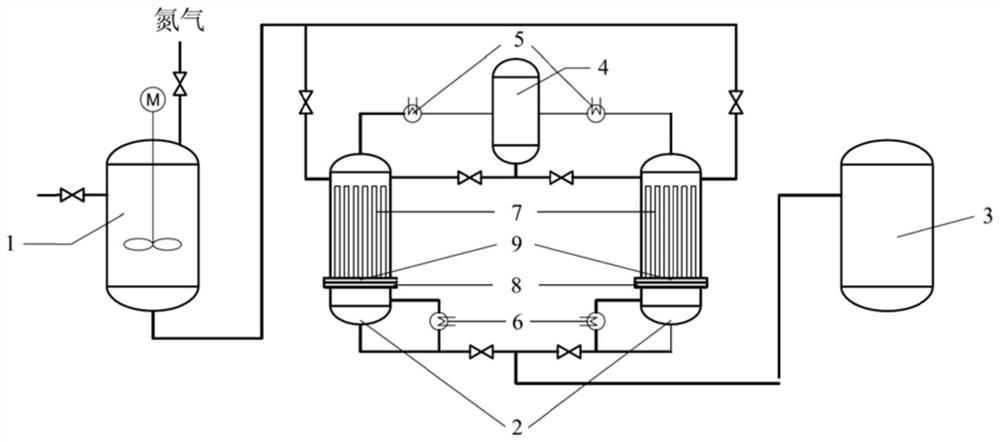

Embodiment 1

[0072] The slag wax (heavy wax content is 70% by weight) in the slag wax storage tank 1 is stirred, and the temperature of maintaining the slag wax is at 110-130 ℃, guarantees that the slag wax is in a flowing state, then feeds nitrogen, and the slag wax Press into the slag wax filtration extraction tank 2, maintain the filtration pressure difference at 0.1-0.3MPa by controlling the nitrogen to carry out the filtration operation, after filtration, pump the obtained heavy wax into the recovery heavy wax storage tank 3, and remove the remaining The slag wax (ie the first slag wax residue, wherein the heavy wax content is 50% by weight) is extracted. Toluene (consumption is 3 times of the volume of the first slag wax residue) is sent into the reboiler 6 for gasification at 150° C., and the toluene gas obtained enters the condenser 5 after passing through the tubular filter 7 (the temperature is 10-15 ℃) to condense, then enter the slag wax filtration extraction tank 2 after the e...

Embodiment 2

[0074] Stir the slag wax (heavy wax content 70% by weight) in the slag wax storage tank 1, and maintain the temperature of the slag wax at 130-150°C to ensure that the slag wax is in a flowing state, then feed nitrogen to press the slag wax into the slag wax filtration extraction tank 2, and maintain the filtration pressure difference at 0.3-0.5MPa by controlling nitrogen to carry out the filtration operation. After filtration, the heavy wax obtained is pumped into the recovery heavy wax storage tank 3, and the remaining The slag wax (ie the first slag wax residue, heavy wax content is 40% by weight) is extracted. Toluene (consumption is 6 times of the volume of the first slag wax residue) is sent into the reboiler 6 for gasification at 130° C., and the obtained toluene gas enters the condenser 5 (the temperature is 12-15 ℃) condenses, then enters the slag wax filtration extraction tank 2 to extract the first slag wax residue after passing through the extraction solvent recove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com