Use method of drying device for clammy ore product sample

A technology of drying device and mineral products, which is applied in the preparation, drying, drying machine and other directions of test samples, can solve the problems of increasing the drying air intake, increasing the energy consumption of blasting, and low heating efficiency, and saving energy The effect of manpower, reducing safety accidents, and reasonable equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

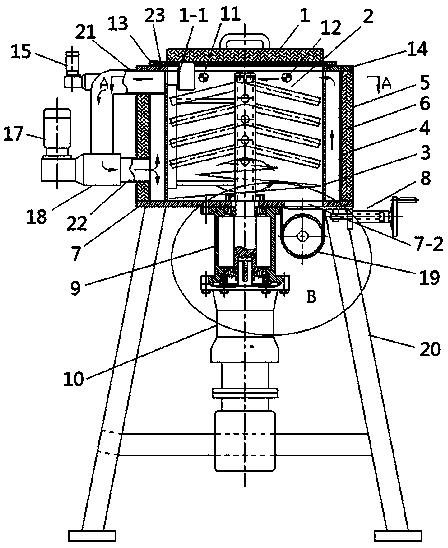

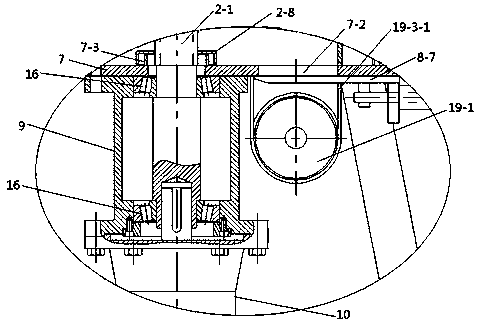

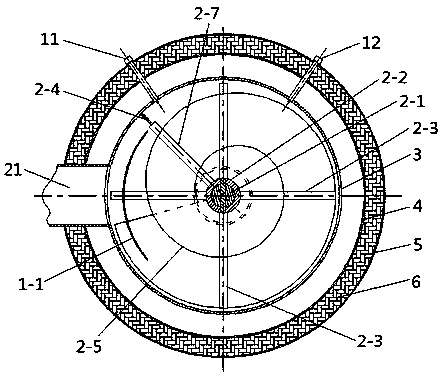

[0056] like Figure 1 to Figure 15 As shown, a drying device for viscous-wet mineral product sample preparation, including a barrel cover 1, a stirring assembly 2, a stainless steel inner cylinder 3, a gas-heat layer intermediate cylinder 4, a steel outer cylinder 5, an insulation layer 6, Lower flange 7, insert plate assembly 8, connecting device 9, cycloid reducer 10, temperature detection head 11, humidity detection head 12, hinge 13, upper flange 14, dehumidifier 15, bearing I 16 , heating fan 17, heater 18, auger assembly 19, support 20.

[0057] The bung 1 is circular, and a windshield 1-1 is provided on the inside of the bung 1 .

[0058] The upper flange 14 is annular, and a sealing ring groove 14-1 is arranged on the surface of the upper flange 14 .

[0059] The lower flange 7 is circular, and the inner surface of the lower flange 7 is provided with a stirring shaft hole 7-1 and a square discharge port I7-2, and a circle of vertical walls 7-3 is provided along the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com