Mechanical force-assisted solid-phase synthesis method of lithium titanate negative electrode material

A negative electrode material, solid-phase synthesis technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of uneven product particles, high energy consumption, easy agglomeration, etc., to achieve stable product performance, inhibition of agglomeration and two effect of secondary growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

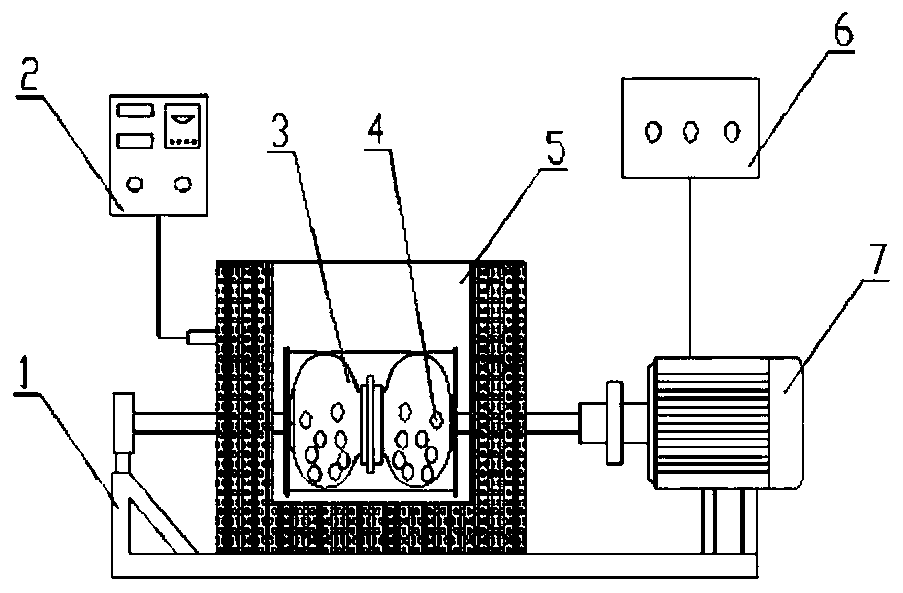

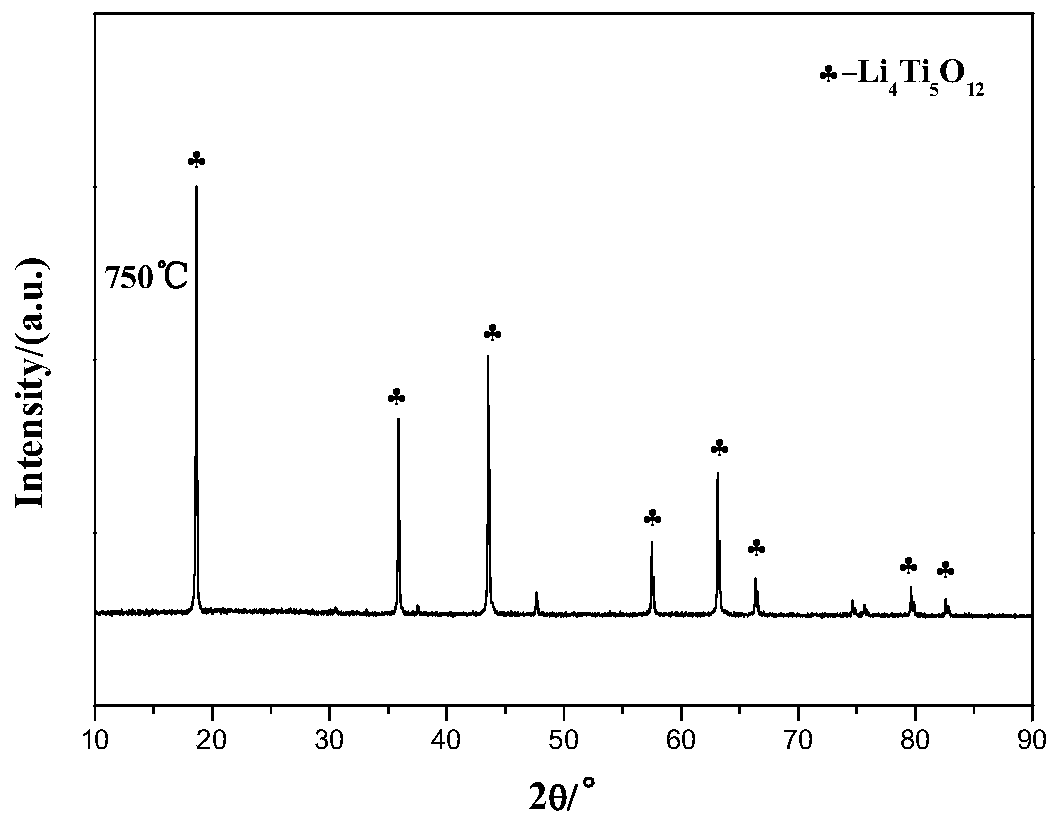

[0053] Implementation Case 1: LiOH·H 2 O and TiO 2 Mix according to Li:Ti=0.82:1, put stainless steel grinding balls and materials into the ball milling tank according to the ball-to-material ratio of 10:1, start the ball mill motor to make the grinding balls stir, grind and crush the materials, and run the high temperature furnace at the same time, Set the heating rate to 5°C / min, raise the temperature to 750°C and keep it warm for 3.5h, wait for the equipment to cool down naturally, then take out the product to obtain pure phase Li 4 Ti 5 o 12 .

[0054] Such as Figure 2-Figure 4 Shown, the prepared Li in embodiment 1 4 Ti 5 o 12 The performance in physical and chemical property testing is very good.

Embodiment example 2

[0055] Implementation Case 2: Put Li 2 CO 3 with TiO 2 Mix according to Li:Ti=0.83:1, put zirconia grinding balls and materials into the ball mill pot according to the ball-to-material ratio of 8:1, start the ball mill motor to make the grinding balls stir, grind and crush the materials, and run the high-temperature furnace at the same time , set the heating rate to 3°C / min, raise the temperature to 760°C for 4 hours, wait for the equipment to cool naturally, take out the product, and obtain pure phase Li 4 Ti 5 o 12 .

Embodiment example 3

[0056] Implementation Case 3: Put Li 2 CO 3 Mix with metatitanic acid according to Li:Ti=0.85:1, put zirconia grinding balls and materials into the ball mill tank according to the ball-to-material ratio of 15:1, start the ball mill motor to make the grinding balls stir, grind and crush the materials, At the same time, run the high-temperature furnace, set the heating rate at 10°C / min, raise the temperature to 780°C and keep it for 4.5h, wait for the equipment to cool down naturally, and take out the product to obtain pure phase Li 4 Ti 5 o 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com