Filter for carbon ion terahertz characteristic spectral line detection and preparation method thereof

A characteristic spectral line and terahertz technology, which is applied in the field of terahertz and semiconductor micromachining, can solve the problems that affect the transmittance, cannot meet the fine structure characteristic spectral line detection of carbon ions, reduce the transmittance, etc., and achieve simple composition, Improved reliability, integrability, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

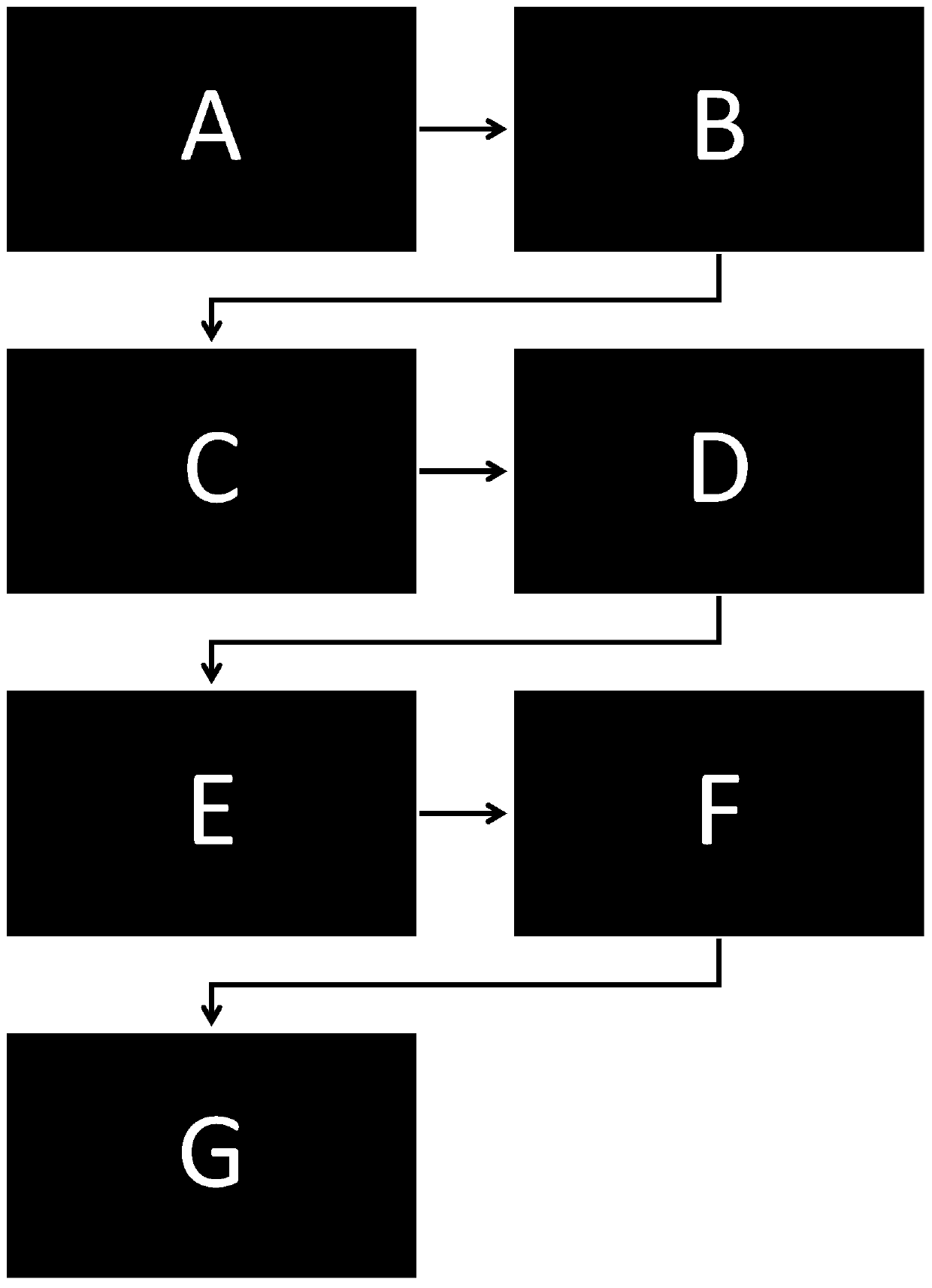

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described

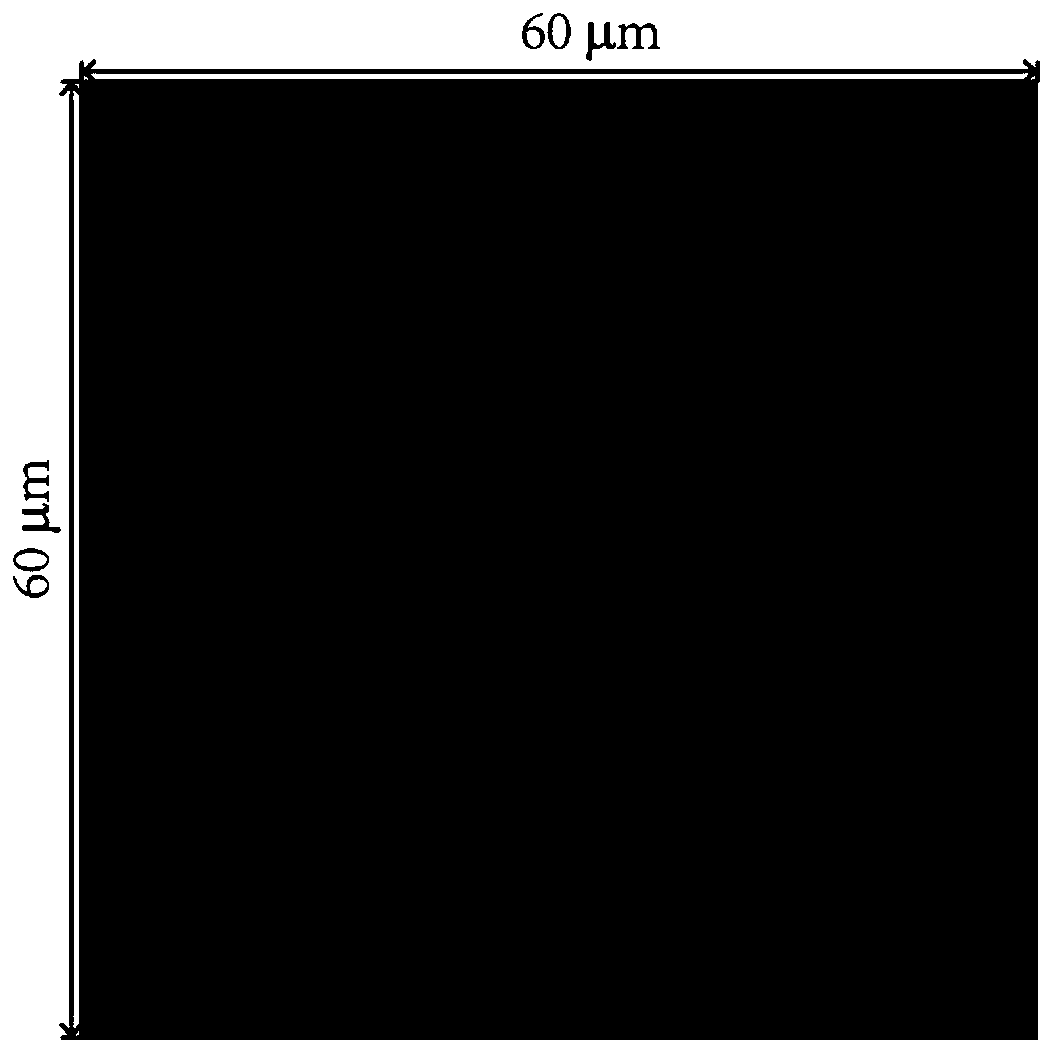

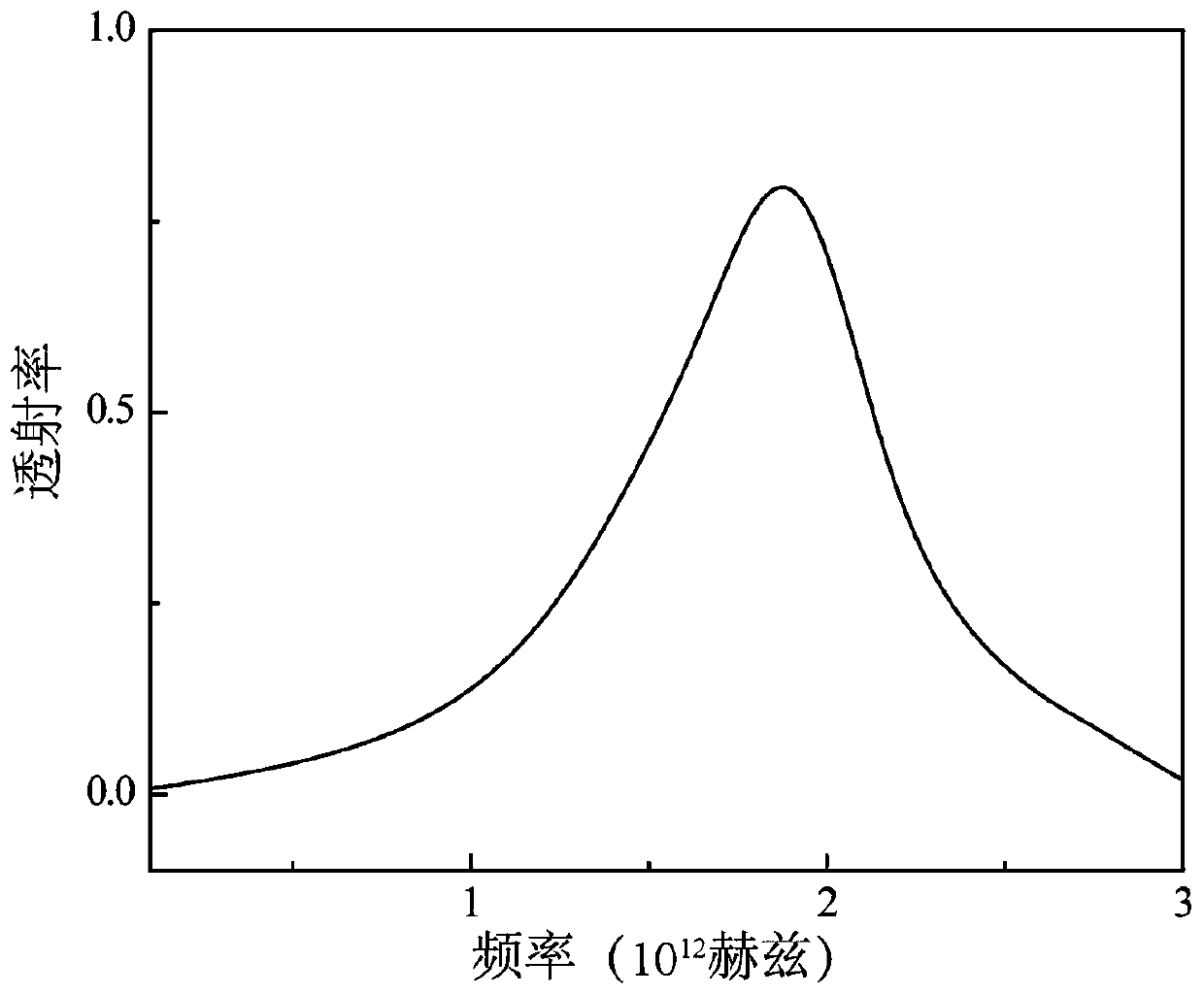

[0017] Filters for the detection of carbon ion terahertz characteristic lines (as attached figure 1 shown). It includes the main horizontal axis 1, the secondary horizontal axis 2, and the vertical axis 3, wherein the vertical axis 3 passes through the middle of the main horizontal axis 1 and the secondary horizontal axis 2.

[0018] The resonance unit is a metal hollow layer, the substrate is a polyimide with a thickness of 25 μm, and the metal layer of the resonance unit is a 200nm gold layer.

[0019] Further, the main horizontal axis 1 is 16 μm long and 3 μm wide;

[0020] The secondary horizontal axis 2 is 8 μm long and 2 μm wide;

[0021] The longitudinal axis 3 is 49 μm long and 2 μm wide;

[0022] The distance from the lower edge of the main horizontal axis 1 to the center of the vertical axis 3 is 9 μm;

[0023] The lower edge of the secondary horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com