Underwater super-oleophobic antifreeze organic hydrogel and preparation method and application thereof, coating, oil-water separation mesh and preparation method thereof

An underwater superoleophobic, oil-water separation net technology, applied in the directions of gel preparation, liquid separation, separation methods, etc., can solve the problems of poor mechanical properties, expensive raw materials, and will be frozen, and achieves good oil-water separation effect, comprehensive The effect of good performance and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing an underwater super oleophobic and antifreeze organic hydrogel, which is used for preparing the underwater super oleophobic and antifreeze organic hydrogel provided by the invention. The method comprises: mixing polyvinyl alcohol, antifreeze liquid and nanoparticles uniformly and then freezing to obtain an organic hydrogel. Specific steps are as follows:

[0036] S1. Mix polyvinyl alcohol and antifreeze evenly to obtain a mixed solution.

[0037] Specifically, antifreeze and polyvinyl alcohol are placed in a container. In order to enable the antifreeze and polyvinyl alcohol to disperse evenly with each other, after the two are added to the container, the ambient temperature is raised to 75-99°C, and the stirring is continued for at least 60°C. ~ min to obtain a mixed solution that is well mixed.

[0038] S2, uniformly mixing the mixed solution and the nanoparticles.

[0039] Specifically, keep the mixed solution at an env...

Embodiment 1

[0048] The preparation method of the underwater super-oleophobic antifreeze organic hydrogel provided in this embodiment includes:

[0049] Put 1.6g of polyvinyl alcohol and 20ml of antifreeze into a 100ml beaker, raise the ambient temperature to 95°C, and keep stirring for 60min to obtain a clear mixed solution.

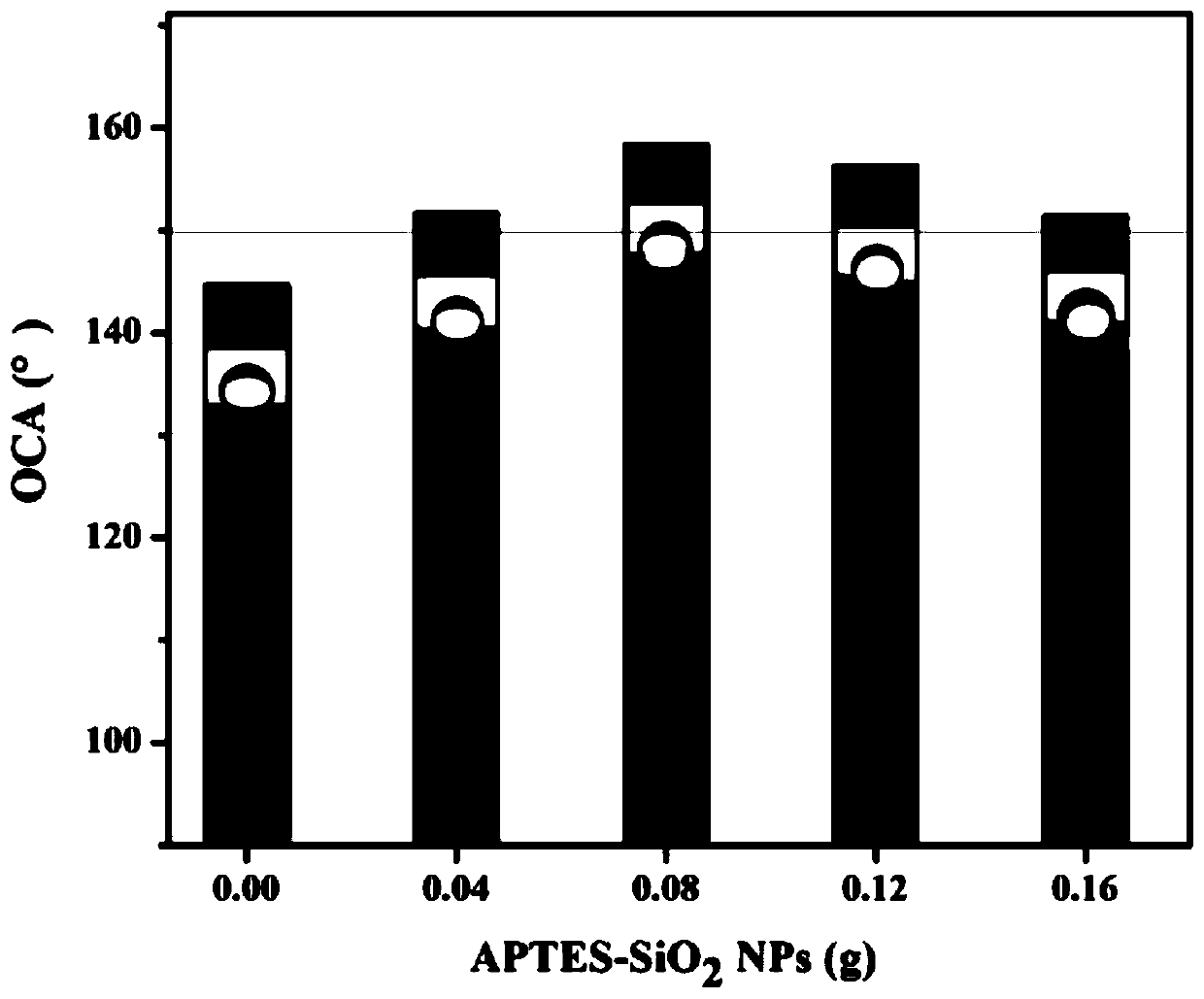

[0050] Then, continue to maintain 95°C, add 0.08g of nanoparticles to the clear mixed solution, and keep stirring until the nanoparticles are evenly dispersed into the mixed solution, and the underwater superoleophobic and antifreeze organic hydrogel provided in this example is obtained.

[0051] In this embodiment, the antifreeze solution is an aqueous solution of ethylene glycol, and in the aqueous solution of ethylene glycol, the mass ratio of ethylene glycol to water is 4:1. The nanoparticles are silica nanoparticles.

[0052] The preparation method of the oil-water separation net provided in this embodiment includes:

[0053] Choose a metal mesh with a pore s...

Embodiment 2

[0055] The preparation method of the underwater super-oleophobic antifreeze organic hydrogel provided in this embodiment includes:

[0056] Put 1g of polyvinyl alcohol and 20ml of antifreeze into a 100ml beaker, raise the ambient temperature to 75°C, and keep stirring for 100min to obtain a clear mixed solution.

[0057] Then, continue to maintain 75 ° C, add 0.1 g of nanoparticles to the clear mixed solution, and keep stirring until the nanoparticles are evenly dispersed into the mixed solution, and the underwater super oleophobic antifreeze organic hydrogel provided in this example is obtained.

[0058] In this embodiment, the antifreeze solution is an aqueous glycerin solution, and in the aqueous glycerin solution, the mass ratio of glycerin to water is 1:2. The nanoparticles are aluminum hydroxide nanoparticles.

[0059] The preparation method of the oil-water separation net provided in this embodiment includes:

[0060] Choose a metal mesh with a pore size of 30 μm, imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com