Joint-free annular conveying belt wound by anti-tear fiber rope

An endless conveyor belt and tear-proof technology, applied in the direction of belts, other household appliances, household appliances, etc., can solve the problems of heavy belt body, easy deviation of belt, and easy breaking of joint parts, so as to reduce labor intensity and labor. cost, saving raw material costs, avoiding the effect of delamination problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

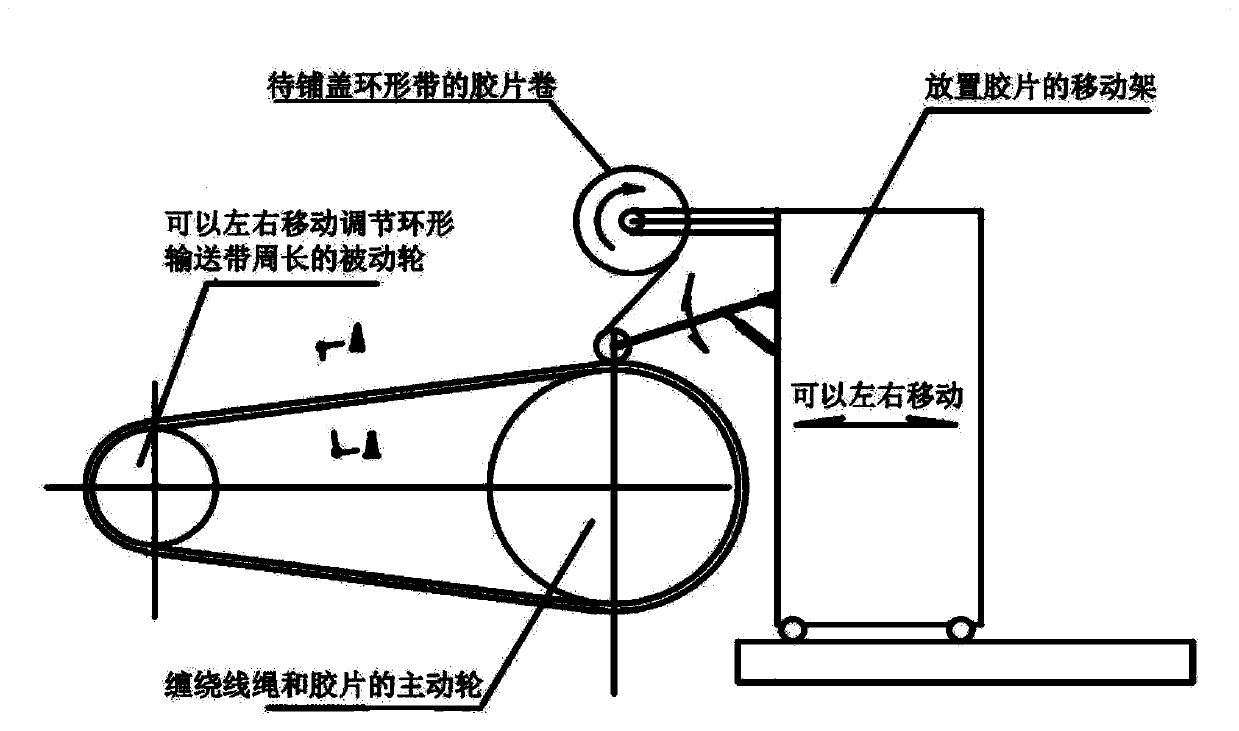

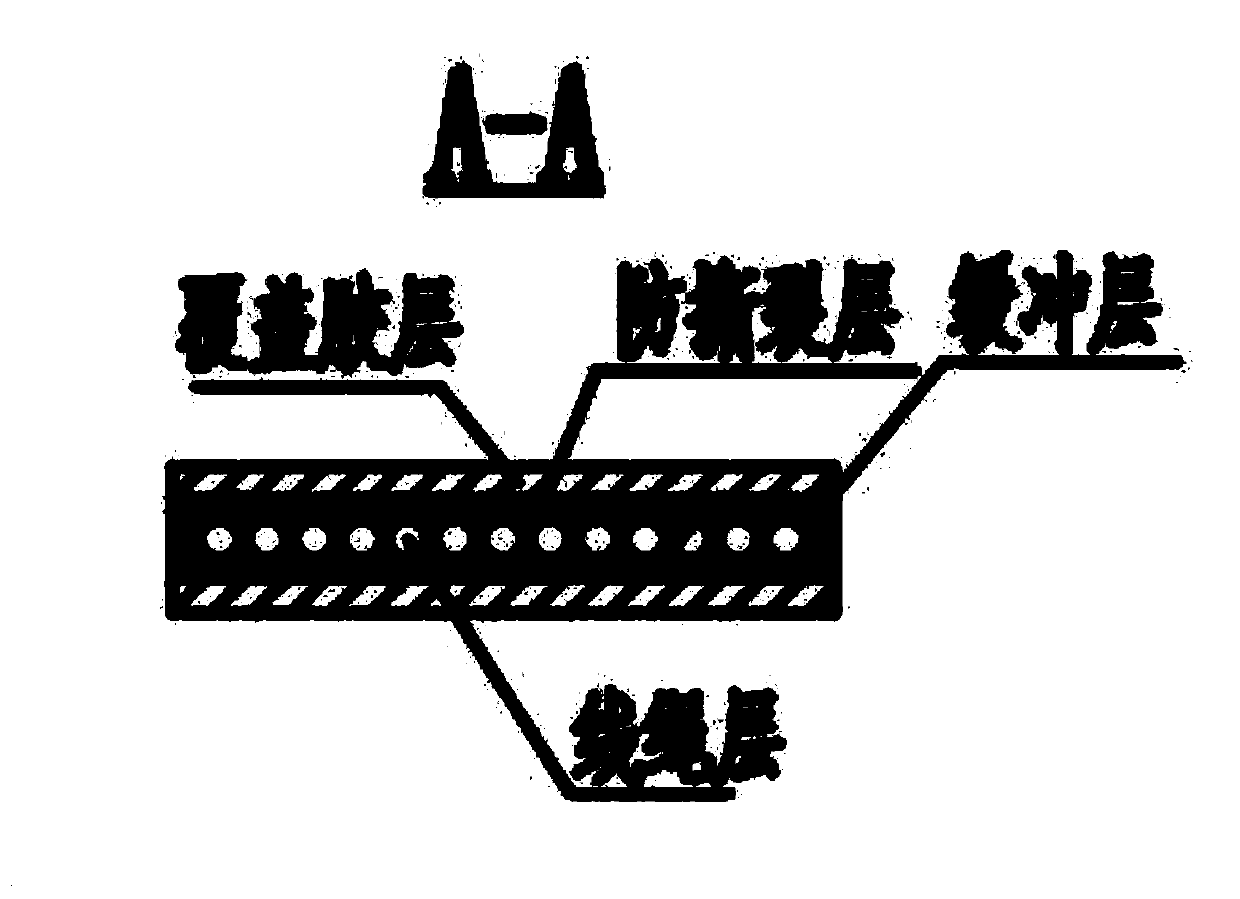

[0019] combined with figure 1 , with figure 2 .

[0020] When the present invention is implemented in practice, (1) prepare glue: put glue and gasoline in a ratio of 1 to 3.5, put it into a beater and stir, after stirring for 30 minutes, discharge the glue, and put it into a container;

[0021] (2) Select a cord with appropriate strength: select the appropriate cord according to the breaking strength of the belt. For example: if the conveyor belt requires a breaking strength of 400N / mm, then choose a 2*3 structural cord.

[0022] The breaking strength of the cord is shown in the table below:

[0023]

[0024] (3) Wind the soaked wire rope on the CNC double-drum wire winding machine: input the winding speed 30r / min, the wire rope arrangement density 30 / 100mm~100 / 100mm on the CNC display screen, and input the circular conveying The inner circumference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com