Preparation method of graphene oxide membrane/poly(4-vinylpyridine)/three-dimensional flower-shaped micro-silver composite material

A vinylpyridine and graphene film technology, applied in the coating and other directions, can solve the problems such as the influence of the reproducibility of the noble metal morphology, the limitation of the practical application effect, and the increase of reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

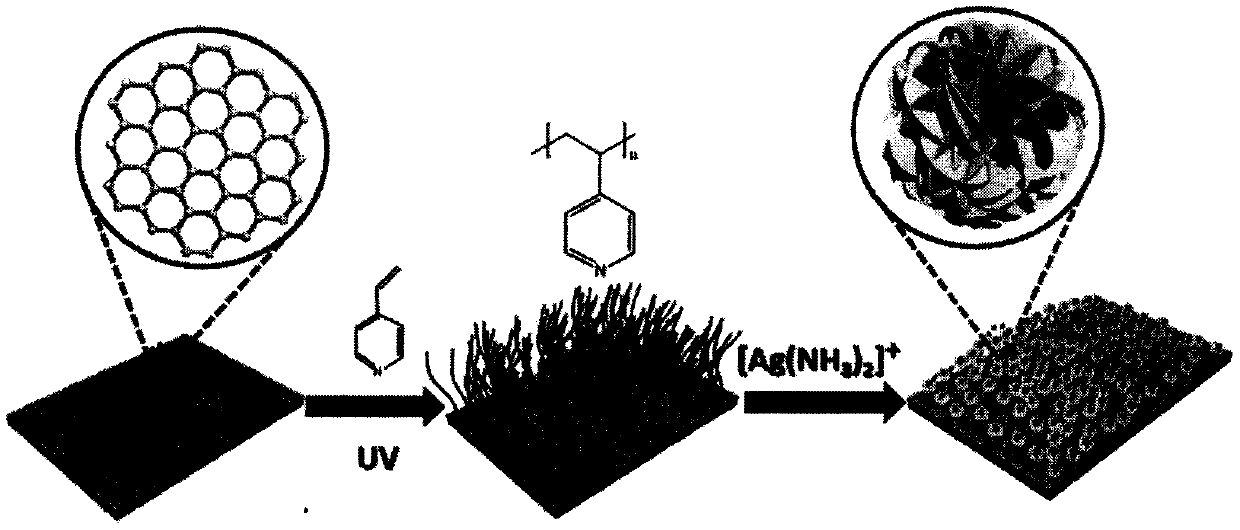

[0016] The present invention relates to a preparation method of graphene oxide film / poly-4-vinylpyridine / three-dimensional flower-like micron silver composite material, comprising step 1, step 2 and step 3,

[0017] Step 1: Drop the ethanol solution of graphene oxide (GO) on the silica gel stamp, transfer GO to the substrate by stamp imprint transfer method, and obtain the GO film after the ethanol volatilizes;

[0018] Step 2: Soak the obtained GO membrane into a sealed tube containing 4-vinylpyridine (4VP) monomer, fill it with nitrogen, and irradiate it with ultraviolet light for 30-180min. After the reaction, take out the GO membrane and rinse, wash and dry , get GO film / P4VP;

[0019] Step 3: Soak the obtained GO membrane / P4VP directly in the silver ammonia solution for 10min to 12h to obtain the graphene oxide membrane / poly 4-vinylpyridine / three-dimensional flower-like micron silver composite material.

[0020] In the above step 1, as for the substrate, any inorganic ma...

Embodiment 1

[0027] The schematic diagram of the preparation process is shown in figure 1 shown.

[0028] Step 1: ultrasonically disperse graphene oxide in an ethanol solution, and prepare a 0.05 mg / mL ethanol solution of graphene oxide. The ethanol solution of graphene oxide was dropped on the silica gel stamp, and the GO was transferred to the silicon wafer by the stamp imprint transfer method, and the ethanol was removed by natural drying to obtain the GO film.

[0029] Step 2: Soak the obtained GO film in a sealed tube containing 4-vinylpyridine (4VP) monomer, fill it with nitrogen, and irradiate it with ultraviolet light with a wavelength of 350nm for 60min at room temperature. After the reaction, take out the GO film and wash it with chloroform The P4VP polymer not grafted onto the GO surface was washed away to obtain GO membrane / P4VP.

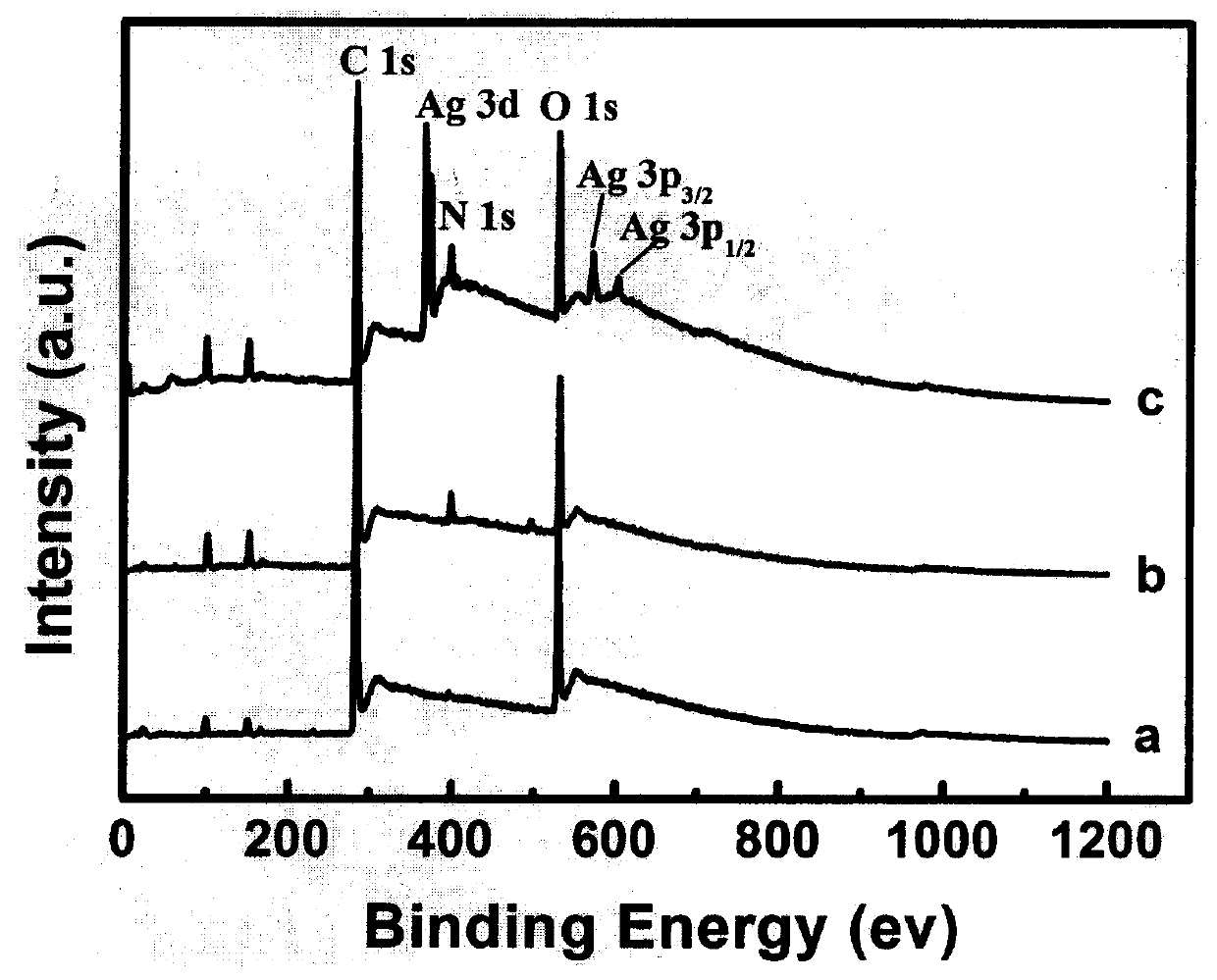

[0030] Step 3: Soak the obtained GO membrane / P4VP directly in 0.02mol / L silver ammonia solution for 1 hour, take it out, wash it and dry it to obt...

Embodiment 2

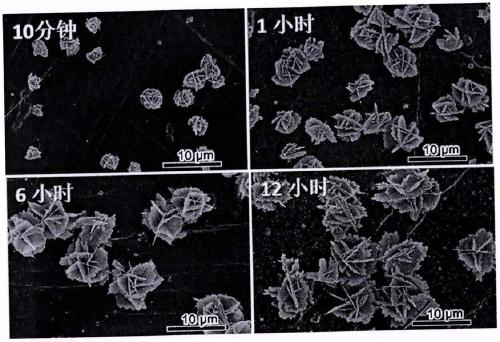

[0034] Other conditions are as shown in Example 1, only the time for soaking the GO membrane / P4VP in step 3 into the 0.02mol / L silver ammonia solution is extended from 1h to 12h. SEM of Ag on the surface of GO membrane-g-P4VP as image 3 shown, compared image 3 In the small figure, it can be seen that the size and shape of the flower-like micron silver structure can be regulated by changing the reaction time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com