Fischer-Tropsch synthesis oil hydrofining method

A Fischer-Tropsch synthetic oil and hydrofining technology, which is applied in the field of oil hydrogenation conversion, can solve problems such as difficulty in maintaining stable operation, coking of catalysts, and high heat, and achieve stable operation of the reaction, high conversion rate, and reduced reaction exothermic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

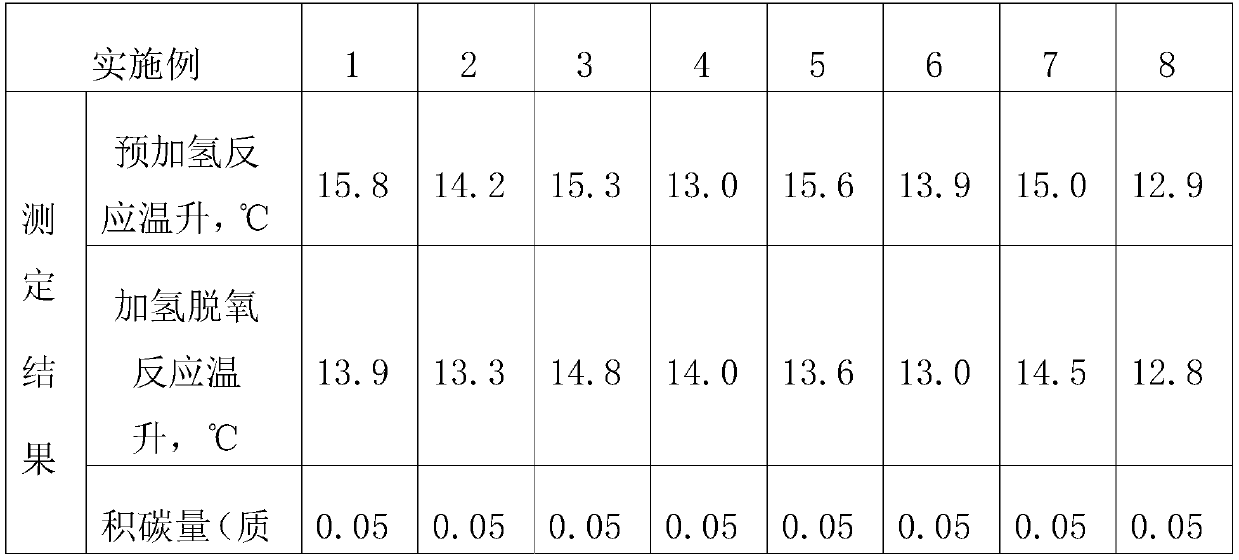

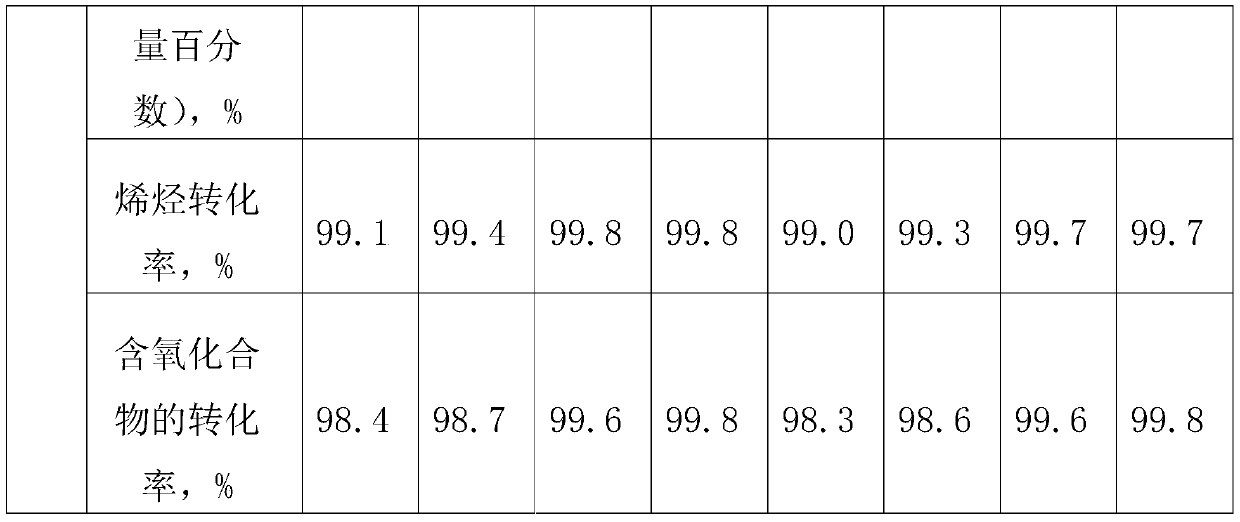

Embodiment 1

[0028] This embodiment provides a method for hydrofinishing of Fischer-Tropsch synthetic oil, comprising:

[0029] S1, the Fischer-Tropsch synthetic oil is mixed with hydrogen after being metered by a metering pump, and a noble metal catalyst is used, wherein the noble metal is platinum Pt, the content of Pt is 5wt%, the carrier is alumina, and the specific surface area of alumina is 350m 2 / g, the control reaction temperature is 120°C, the pressure is 2MPa, and the space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 300, low-temperature pre-hydrogenation reaction is carried out, and the unsaturated olefins in the Fischer-Tropsch synthetic oil are converted into corresponding saturated hydrocarbons to obtain pre-hydrogenation products;

[0030] S2. The pre-hydrogenation product obtained in S1 is subjected to a deep hydrodeoxygenation reaction, using a high-nickel catalyst, wherein the content of Ni is 45wt%, the carrier is alumina, and the specific surface are...

Embodiment 2

[0034] This embodiment provides a method for hydrofinishing of Fischer-Tropsch synthetic oil, comprising:

[0035] S1, the Fischer-Tropsch synthetic oil is mixed with hydrogen after being metered by a metering pump, and enters the first reactor, which is filled with a noble metal catalyst, wherein the noble metal is platinum Pt, wherein the content of Pt is 3wt%, and the carrier is alumina, The specific surface area of alumina is 350m 2 / g, the control reaction temperature is 140°C, the pressure is 4MPa, and the space velocity is 2.0h -1 , the volume ratio of hydrogen to oil is 600, low-temperature pre-hydrogenation reaction is carried out, and the unsaturated olefins in the Fischer-Tropsch synthetic oil are converted into corresponding saturated hydrocarbons to obtain pre-hydrogenation products;

[0036] The pre-hydrogenation product obtained in steps S2 and S1 enters the second reactor, which is filled with a high-nickel catalyst, wherein the content of Ni is 30wt%, and t...

Embodiment 3

[0040] This example adopts a method similar to that of Example 2 to carry out the hydrofining of Fischer-Tropsch synthetic oil. The difference is that in step S1, the precious metal catalyst loaded in the first reactor has a Pt content of 0.5 wt%, and the low-temperature preheating The conditions of the hydrogenation reaction are: the reaction temperature is 160°C, the pressure is 6MPa, and the space velocity is 5.0h -1 , the volume ratio of hydrogen to oil is 1000; in the S2 step, the Ni content of the high-nickel catalyst packed in the second reactor is 43wt%, and the conditions of the deep hydrodeoxygenation reaction are as follows: speed is 2h -1 , the volume ratio of hydrogen to oil is 1000; the circulation ratio of hydrorefined products is 40%.

[0041] Using the same method as in Example 2 to measure the temperature rise in the prehydrogenation reaction and the hydrodeoxygenation reaction, the amount of carbon deposition, and the conversion rate of olefins and oxygenat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com