Wall-through sleeve capable of fixing external wall heat-preservation plate to prevent water seepage of external wall

An external wall insulation and wall-penetrating sleeve technology is applied in thermal insulation, building thermal insulation materials, pipes, etc., which can solve the problems of increased construction consumables, water seepage of external walls, cumbersome construction process, etc., so as to reduce construction consumables, reduce construction costs, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

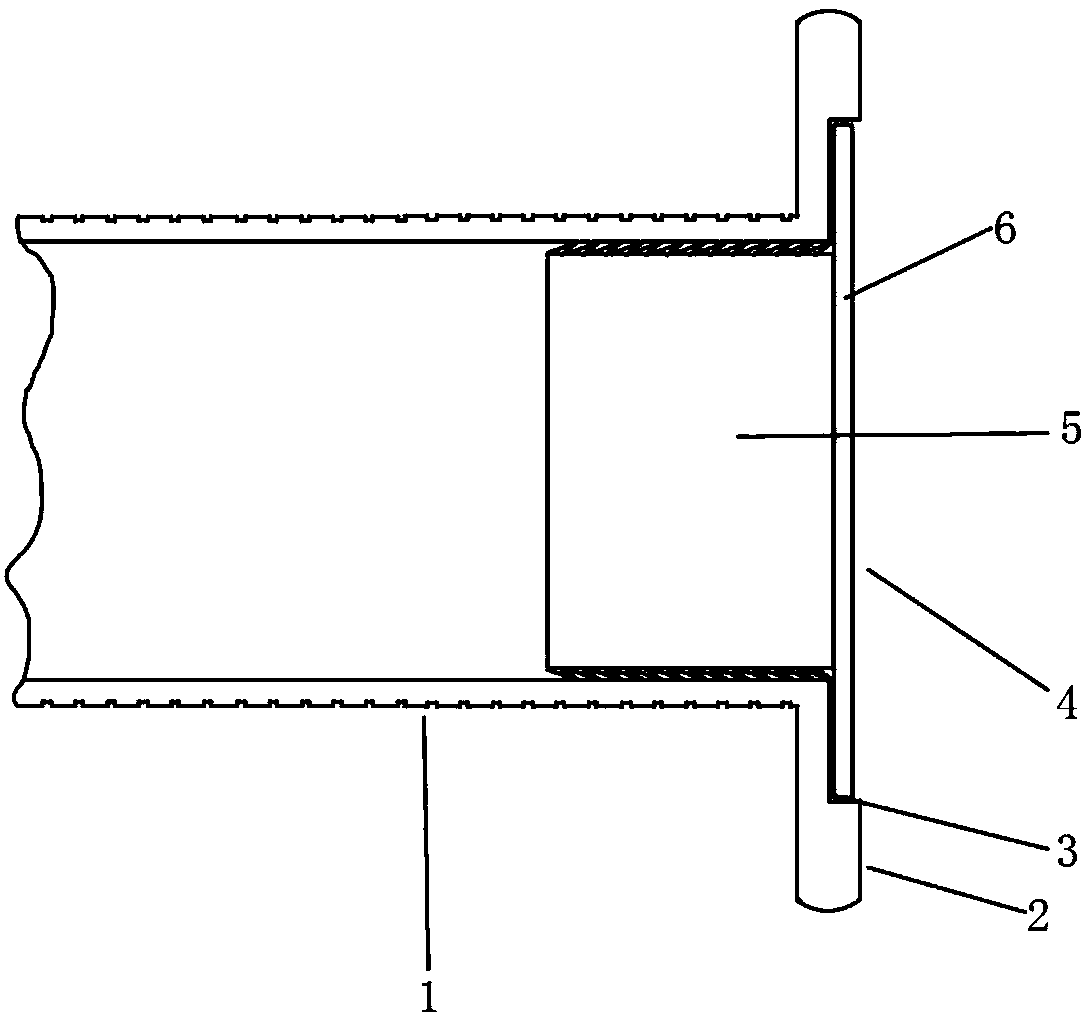

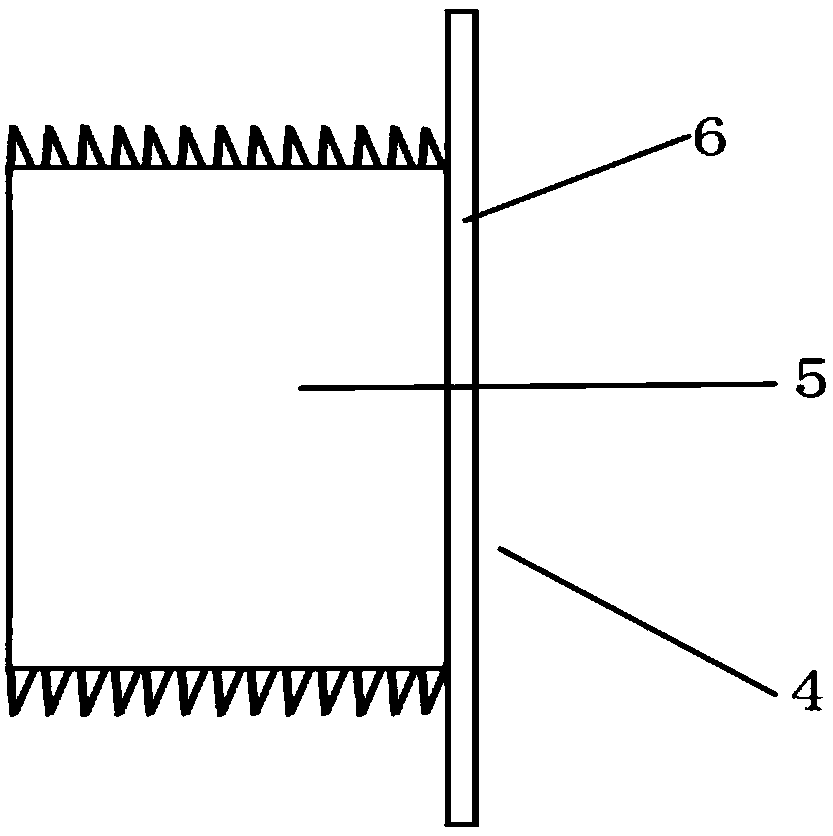

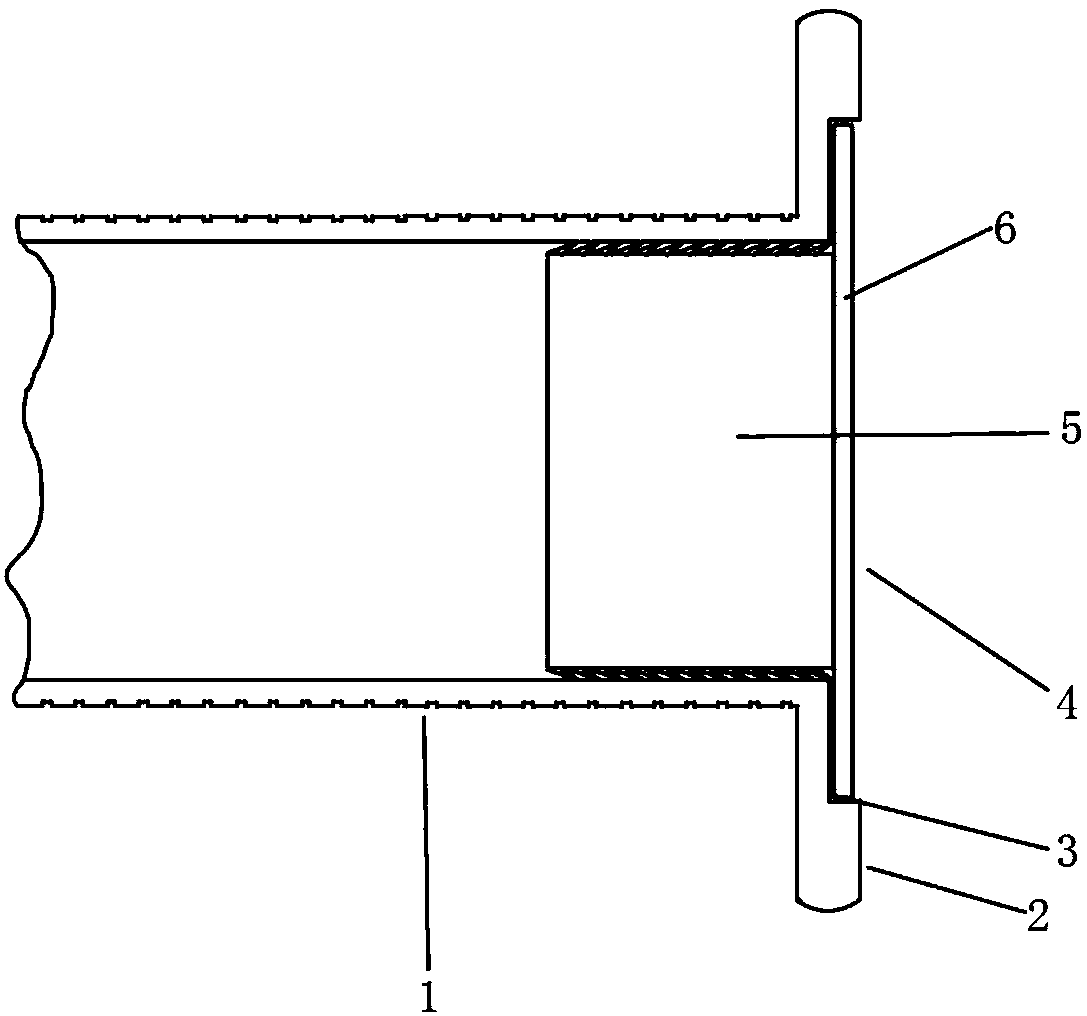

[0016] Such as Figure 1-2 As shown, a wall-piercing sleeve capable of fixing an external wall insulation board includes a wall-piercing pipe (1). One end of the flange (2) is provided with a flange (3) around the inner hole of the flange (2), and the pipe plug (5) provided with the pipe plug (4) is connected with the wall pipe (1 ) is inserted into the inner hole of one end of the flange (2) for connection, the pipe plug head (5) is hollow and circular and has a raised soft thread on the outer wall, and the pipe plug cap (6) provided with the pipe plug (4) ) sinks into the missing platform (3) in the inner hole of the flange, and the thickness of the plug cap (6) is slightly smaller than the thickness of the missing platform (3) in the flange in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap