Beneficiation method for copper-cobalt sulfide ore containing two types of cobalt-containing minerals

A beneficiation method and copper sulfide technology, applied in flotation, solid separation, etc., can solve the problems of low quality of copper-cobalt mixed concentrate and affect the quality of concentrate, and achieve good technical indicators, efficient beneficiation and smelting process, and easy on-site management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A copper-cobalt sulfide ore contains 1.32% copper, 0.52% cobalt and 3.88% sulfur. The process mineralogy research of the copper-cobalt sulfide ore shows that the copper-bearing minerals in the ore are mainly chalcopyrite, bornite, chalcocite, copper-cobalt sulfide, followed by a small amount of tetrahedrite, copper blue, natural copper and malachite; cobalt-containing minerals are mainly sulfur-copper-cobalt ore, pyrite containing cobalt (same quality), and a small amount of hydrocobalt ore, cobalt, etc.; gangue minerals are mainly dolomite, talc, chlorite, Feldspar, mica, quartz, etc., are a typical two types of cobalt-containing mineral copper-cobalt sulfide ore.

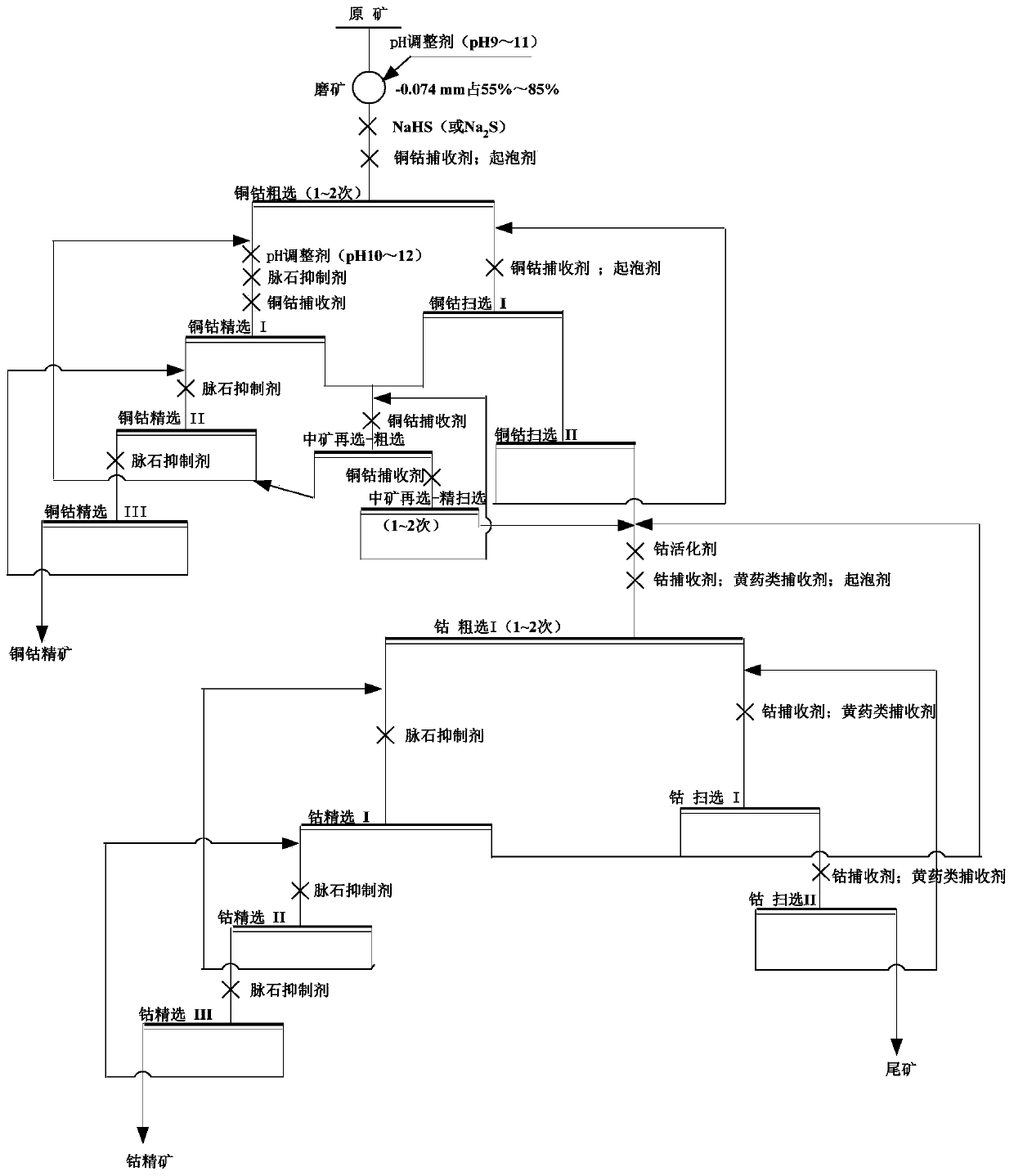

[0045] Such as figure 1 As shown, a beneficiation method containing two types of cobalt-containing mineral copper-cobalt sulfide ore is used to process the above-mentioned two types of cobalt-containing mineral copper-cobalt sulfide ore, including the following steps:

[0046] A. Grinding: wet grinding is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com