Method and application of preparing high-purity multicolor carbon dots by adjusting the morphology of carbon nanocrystals

A carbon nanocrystal and high-purity technology, applied in nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems of difficult industrial production and low purity of carbon quantum dots, and achieve good biocompatibility, low cytotoxicity, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The method and application of the present invention for preparing high-purity multicolor carbon dots by regulating the morphology of carbon nanocrystals comprises the following steps:

[0047] (1) Weigh 0.22g o-aminophenol, measure 20ml alcohol solution, and dissolve o-aminophenol in the alcohol solution;

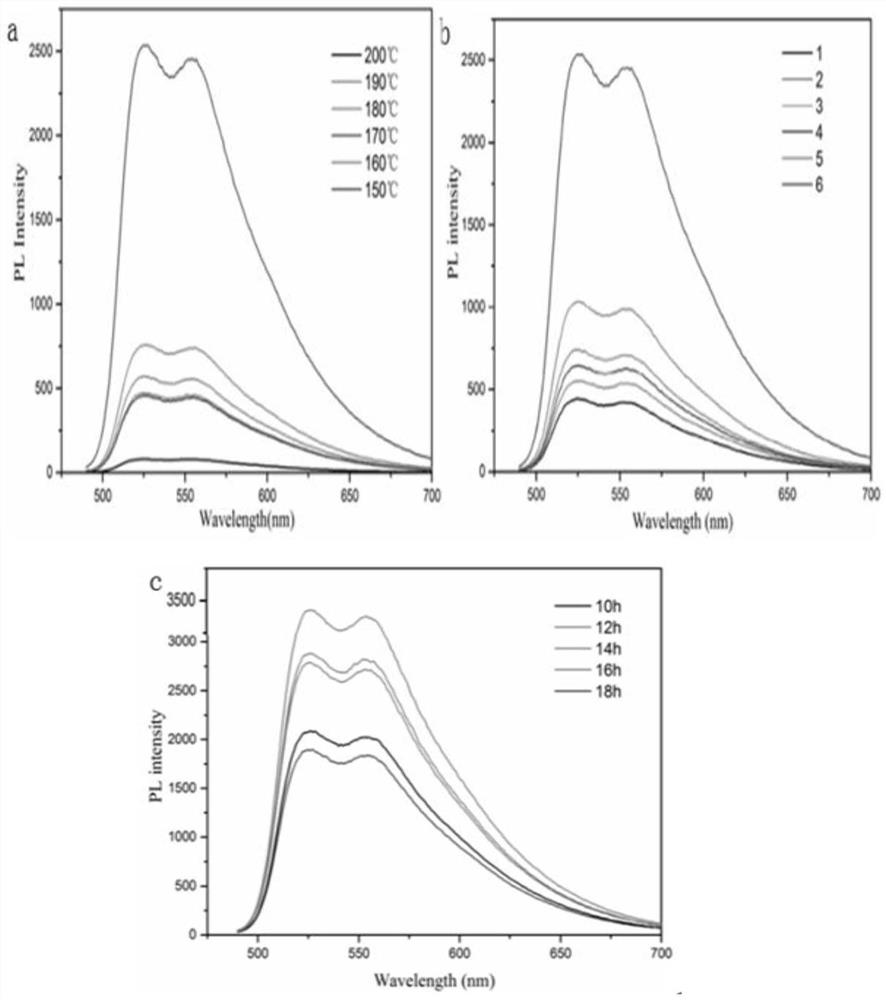

[0048] (2) After the undissolved part of o-aminophenol was ultrasonically treated for 15 minutes, after it was completely dissolved, it was transferred to a 50ml polytetrafluoroethylene-lined hydrothermal synthesis kettle, and reacted in a muffle furnace at 170°C for 16 hours;

[0049] (3) After the reaction, a tan solution with fine suspended particles was obtained. After the solution was centrifuged at 4000r / min, the lower layer of solid was removed and dried to obtain carbon quantum dot nanocrystals.

[0050] (4) High-purity multicolor carbon dots can be prepared by dissolving carbon nanocrystals in corresponding polar solvents.

[0051] Wherein, the volume ratio...

Embodiment 2

[0055] The present invention adopts the existing hydrothermal preparation process:

[0056] (1) Weigh 0.22g o-aminophenol, measure 20ml alcohol solution, and dissolve o-aminophenol in the alcohol solution;

[0057] (2) After the undissolved part of o-aminophenol was ultrasonically treated for 15 minutes, after it was completely dissolved, it was transferred to a 50ml polytetrafluoroethylene-lined hydrothermal synthesis kettle, and reacted in a muffle furnace at 170°C for 16 hours;

[0058] (3) Rotate the above solution to remove ethanol, control the rotary evaporation conditions as follows: temperature 35°C, vacuum degree 0.085MPa, rotation speed 100rpm; dissolve in secondary water, centrifuge to remove insoluble matter, dialyze for three days, freeze-dry to obtain carbon quantum Dot powder.

[0059] By comparison with Example 1, it can be seen that Example 2 is an existing method for preparing carbon dots, and the quantum yield of carbon dots obtained by it is lower than tha...

Embodiment 3

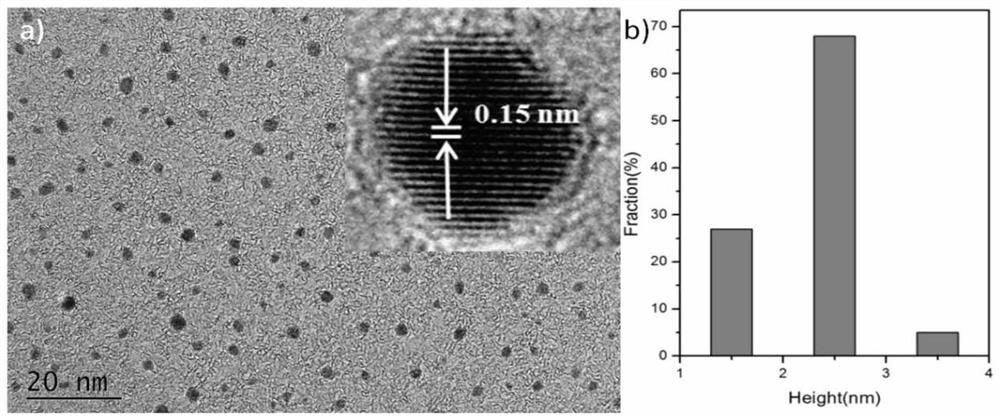

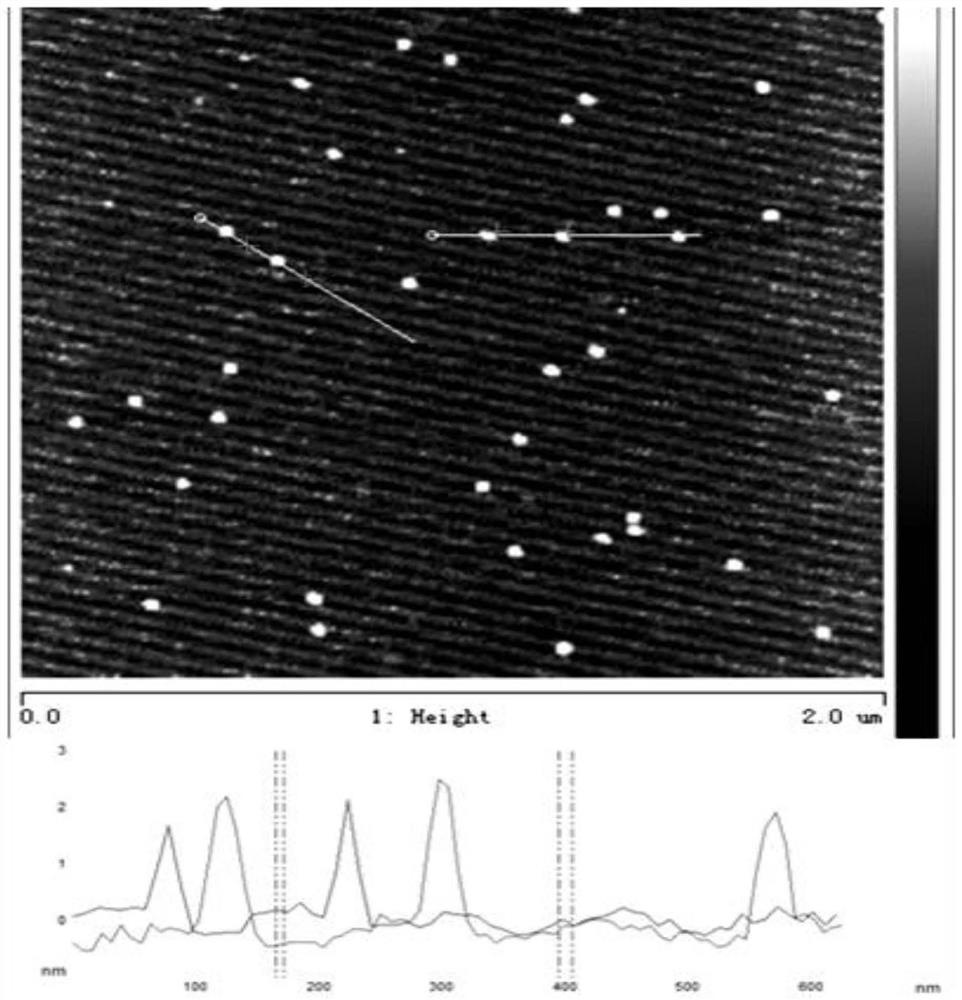

[0061] Carry out high-resolution transmission electron microscope (TEM) and atomic force microscope (AFM) characterization to the carbon quantum dot gained in embodiment 1, as figure 2 , image 3 shown.

[0062] figure 2 TEM image of multicolor fluorescent carbon quantum dots, figure 2 The abscissa in b is: particle size statistics (nm); the ordinate is: the proportion of various particle sizes; image 3 AFM image of multicolor fluorescent carbon quantum dots;

[0063] It can be found from the characterization diagrams of TEM and AFM that the multicolor fluorescent carbon quantum dot crystals prepared by the present invention are neatly arranged and there is no obvious aggregation on the surface. from figure 2 It can be seen from the TEM particle diameter distribution diagram in the figure that the particle diameter of the carbon quantum dots is distributed in the range of 1nm to 4nm, and the atomic force microscope diagram ( image 3 ) shows that the multicolor fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com