A kind of preparation method of thermal paper sensitizer ethylene glycol diphenyl ether

A technology of ethylene glycol diphenyl ether and sensitizer, which is applied in the directions of ether preparation, ester reaction preparation of ether, organic chemistry, etc., can solve the problems of high production cost and low yield, etc., so as to reduce production cost and increase production. Costs, large implementation value, and socioeconomic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

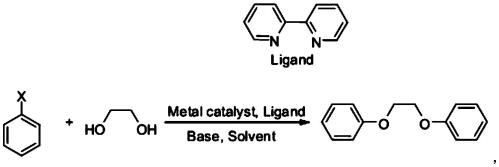

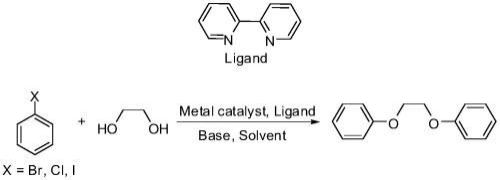

Method used

Image

Examples

Embodiment 1

[0019] In the three-bay flask, add 15.7 g bromobenzene (100 mmol) and 47 ml DMF and stir. Sequentially add 12.7 g of sodium carbonate (120 mmol, 1.2 equivalent), 1.9 g of cuprous iodide (10 mmol, 0.1 equivalence), 1.87 g of 2,2'-bipyridine (12 mmol, 0.1 equivalent) and 7.4 g of ethylene glycol (120 mmol, 1.2 equivalence), the reaction mixture was stirred at 100 °C overnight. After reducing pressure and recovering DMF, 100ml of water and 100ml of toluene were added, and the aqueous phase was extracted three times with 300ml of toluene, and the organic layer was combined. Wash sequentially with water and 5% sodium carbonate. The organic phase was dried with anhydrous sodium sulfate, filtered, and the organic solvent was distilled out after decolorization of activated carbon to obtain 22 grams of crude product, and the crude product was recrystallized by isopropanol and vacuum dried to obtain 19.5 grams of product, with a yield of 91% and a purity greater than 99%.

Embodiment 2

[0021]The basic operation is the same as Example 1, the difference is: the metal catalyst is 1.43 g cuprous bromide (10mmol, 0.1 equivalent). After recrystallization, the crude product was recrystallized to obtain 17.8 grams of product, with a yield of 83% and a purity greater than 99%.

Embodiment 3

[0023] The basic operation is the same as Example 1, the difference is: the metal catalyst is 2.2 g copper bromide (10mmol, 0.1 equivalent). After recrystallization, the crude product was recrystallized to obtain 15.6 grams of product, with a yield of 73% and a purity greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com