High-transparency LED die bond adhesive and preparation method thereof

A high-transparency, crystal-bonding technology, applied in the fields of electronic chemicals and polymer science, can solve the problem of low light extraction efficiency of chips, achieve the effects of good thixotropy, improve efficiency, and improve shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

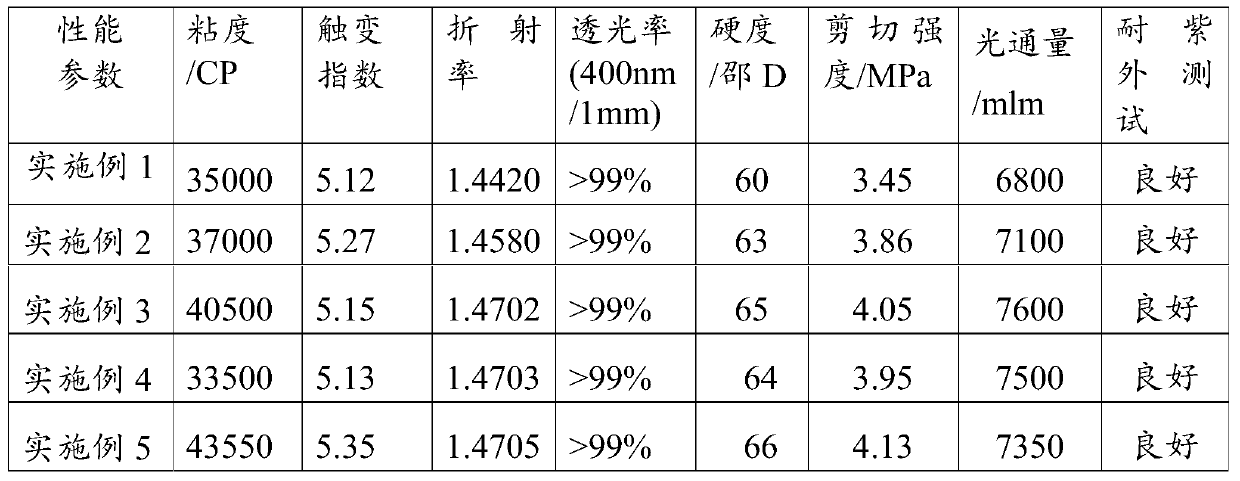

Examples

Embodiment 1

[0055] As an embodiment of a high-transparency LED crystal-bonding adhesive of the present invention, the LED crystal-bonding adhesive includes the following components by weight: 200 g of phenylvinyl silicone resin, 40 g of phenylhydrogen silicone resin, inhibitor (methyl 0.06 g of ethynyl alcohol), 0.32 g of a methylvinylsiloxane-coordinated platinum catalyst, 4.8 g of a binder (allyl glycidyl ether), and 16 g of fumed silica.

[0056] The refractive index of the phenylvinyl silicone resin is 1.44, the refractive index of the phenylhydrogen silicone resin is 1.44, the platinum content of the platinum catalyst is 3000ppm, and the fumed silica is Wacker H30.

[0057] The preparation method of the LED crystal-bonding glue of the present embodiment comprises the following steps:

[0058] (1) Preparation of phenyl vinyl silicone resin:

[0059] (1a) Add 100g of trimethylchlorosilane, 100g of methyltriethoxysilane, 40g of phenyltrichlorosilane, 300g of tetraethyl orthosilicate, 1...

Embodiment 2

[0073] As an embodiment of a high-transparency LED crystal-bonding adhesive of the present invention, the LED crystal-bonding adhesive includes the following components by weight: 200 g of phenylvinyl silicone resin, 45 g of phenylhydrogen silicone resin, inhibitor (methyl 0.06 g of ethynyl alcohol), 0.33 g of a methylvinylsiloxane-coordinated platinum catalyst, 5 g of a binder (allyl glycidyl ether), and 16 g of fumed silica.

[0074] The refractive index of the phenylvinyl silicone resin is 1.46, the refractive index of the phenylhydrogen silicone resin is 1.46, the platinum content of the platinum catalyst is 3000ppm, and the fumed silica is Wacker H30.

[0075] The preparation method of the LED die-bonding adhesive of the present embodiment comprises the following steps:

[0076] (1) Preparation of styrene-based silicone resin:

[0077] (1a) Add 100g of trimethylchlorosilane, 70g of methyltriethoxysilane, 60g of phenyltrichlorosilane, 310g of ethyl orthosilicate, 100g of ...

Embodiment 3

[0091] As an embodiment of the high-transparency LED crystal-bonding adhesive of the present invention, the LED crystal-bonding adhesive includes the following components by weight: 200 g of phenylvinyl silicone resin, 42 g of phenylhydrogen-based silicone resin, inhibitor (methylethynyl Alcohol) 0.06 g, methyl vinyl siloxane-coordinated platinum catalyst 0.33 g, binder (allyl glycidyl ether) 5 g, and fumed silica 16 g.

[0092] The refractive index of the phenylvinyl silicone resin is 1.47, the refractive index of the phenylhydrogen silicone resin is 1.47, the platinum content of the platinum catalyst is 3000ppm, and the fumed silica is Wacker H30.

[0093] The preparation method of the LED die-bonding adhesive of the present embodiment comprises the following steps:

[0094] (1) Preparation of styrene-based silicone resin

[0095] (1a) Add 100g of trimethylchlorosilane, 50g of methyltriethoxysilane, 90g of phenyltrichlorosilane, 330g of tetraethyl orthosilicate, 100g of but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com