Method for inhibiting coking of ethylene cracking device

A technology of ethylene cracking and ethylene cracking raw materials, which is applied in the field of coking suppression in ethylene cracking units, can solve the problem of uneven coking, achieve the effects of reducing coking, saving operating costs, and overcoming uneven coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition of ethylene cracking feed gas is shown in Table 1.

[0030] Table 1

[0031] Component volume% Ethylene0.2 Ethane99.75 Acrylic0.03 Propane0.02

[0032] The coking inhibitor is selected from the gas obtained in the catalytic cracking gas separation section. The composition of the gas is shown in Table 2.

[0033] Table 2

[0034] Component volume% Hydrogen sulfide2.938 hydrogen61.772 Methane23.786 Ethane4.026 Propane3.098 Isobutane1.820 N-butane 1.264 C5

1.296

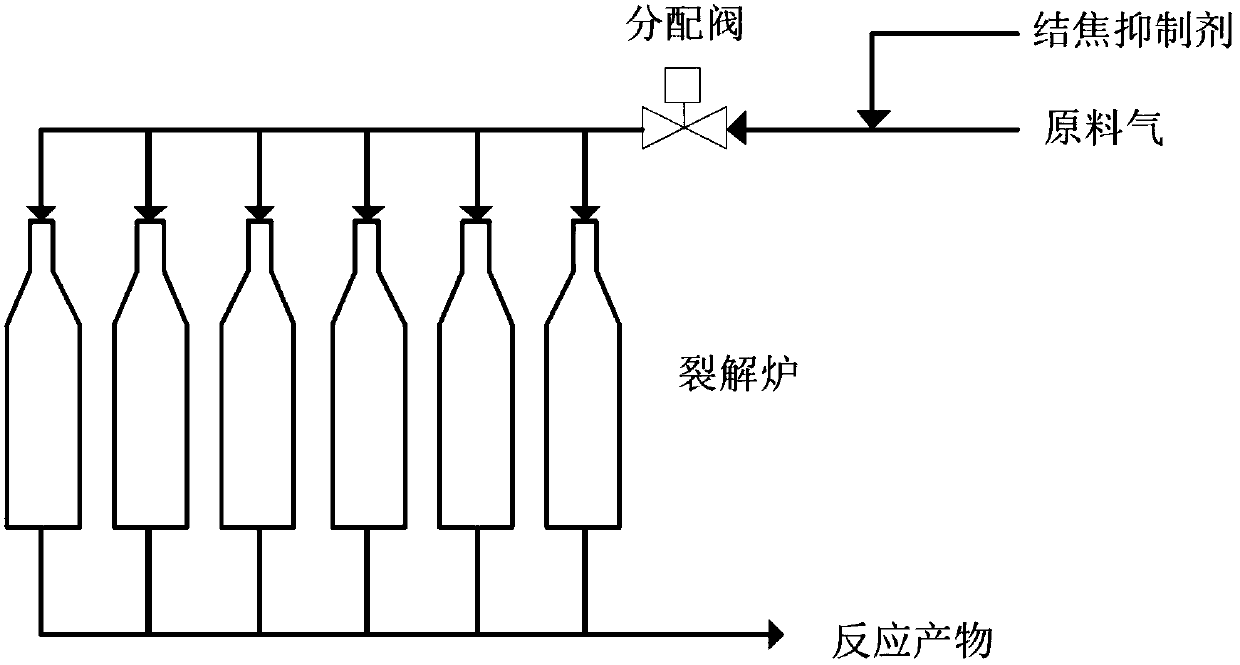

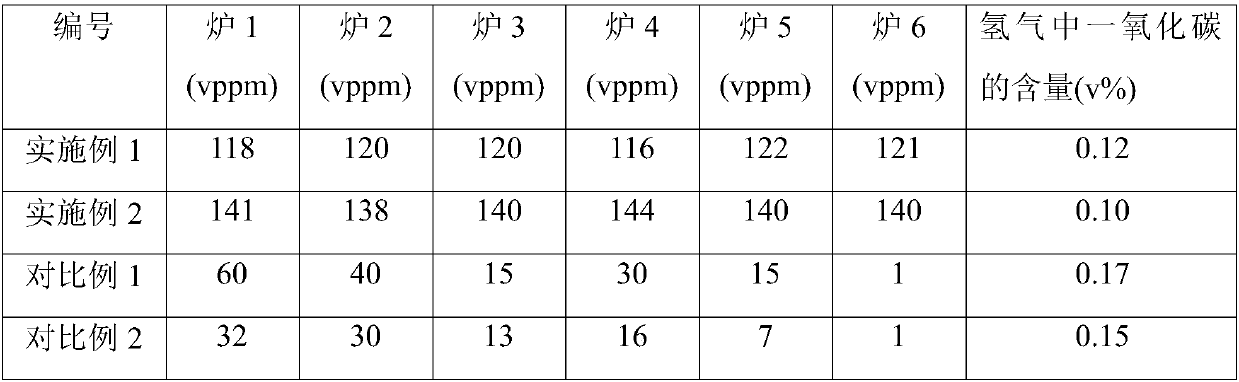

[0035] Such as figure 1 As shown, the coking inhibitor containing hydrogen sulfide shown in Table 2 with a flow rate of 45000ml / min is added to the ethylene cracking feed gas with a flow rate of 30t / h shown in Table 1 (calculated as the sulfide in the coking inhibitor, sulfide The concentration in the ethylene cracking feedstock is 150vppm), so that the coking inhibitor and the gaseous ethylene cracking feedstock enter the ethylene cracking unit together at 60°C. The flow control valve i...

Embodiment 2

[0040] According to the method of Example 1, the difference is that the coking inhibitor containing hydrogen sulfide shown in Table 2 with a flow rate of 60000ml / min is added to the ethylene cracking feed gas with a flow rate of 30t / h shown in Table 1 (using the coking inhibitor The concentration of sulfide in the ethylene cracking feedstock is 200 vppm. The coking inhibitor and the gaseous ethylene cracking feedstock enter the ethylene cracking unit together at 70°C.

[0041] The content of coking inhibitor in 6 groups of cracking furnaces was measured according to the method of Example 1. The results are shown in Table 3.

[0042] The content of carbon monoxide in hydrogen was measured according to the method of Example 1, and the results are shown in Table 3.

[0043] The coking condition of the cracking furnace was detected according to the method of Example 1. After 90 days of operation, the cracking furnace needs to be shut down and the cracking furnace is decoked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com