Flexible surface enhanced Raman detection substrate and preparation method and preparation system thereof

A flexible surface and substrate technology, used in Raman scattering, measurement devices, instruments, etc., can solve the problems of high cost of surface-enhanced Raman detection substrates, low preparation efficiency, and difficulty in controlling the consistency of metal magnetic beads. Good scattering signal enhancement effect, high detection precision and accuracy, and good detection repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

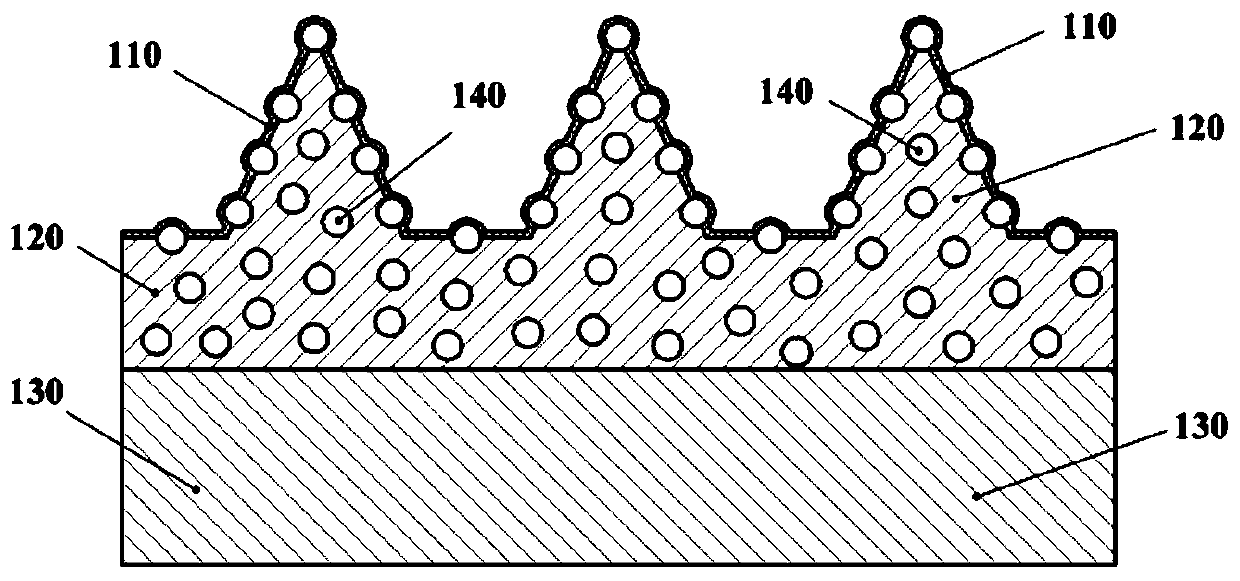

[0053] A flexible surface-enhanced Raman detection substrate based on hierarchical nanostructures, the structure of which is as follows figure 1 shown, including:

[0054] The film substrate layer 130 has a thickness of 20-200 μm, such as 20 μm, 40 μm, 60 μm, 100 μm, 120 μm, 140 μm, 160 μm, 180 μm, 200 μm.

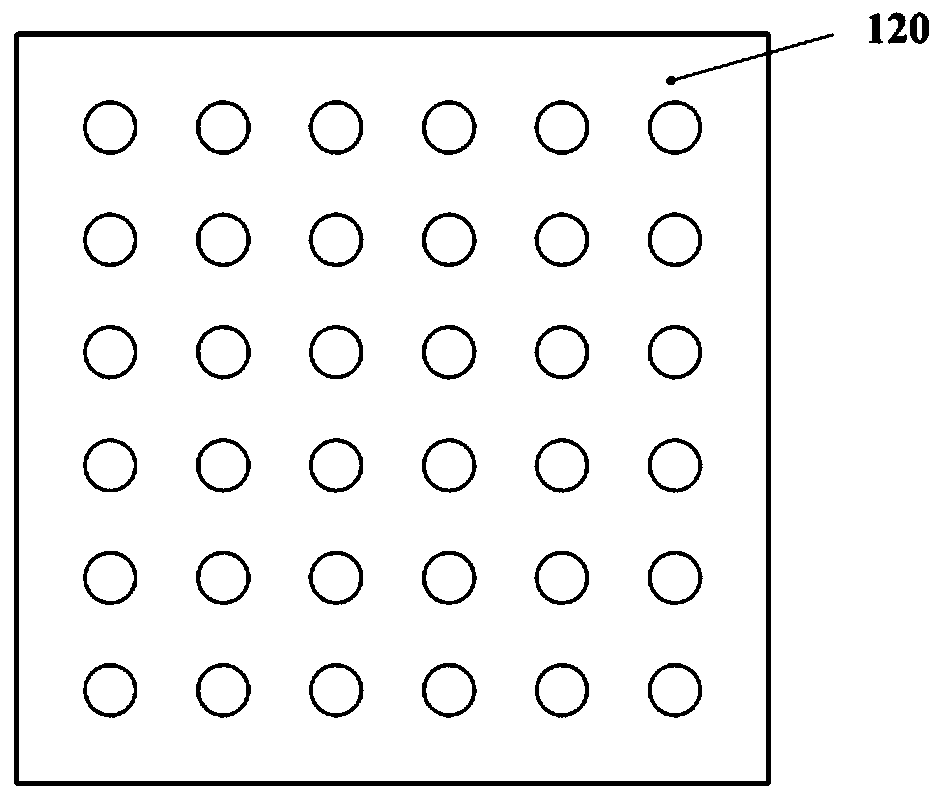

[0055] Cured resin layer 120, attached to the surface of film substrate layer 130, and doped with nano-silver particles 140;

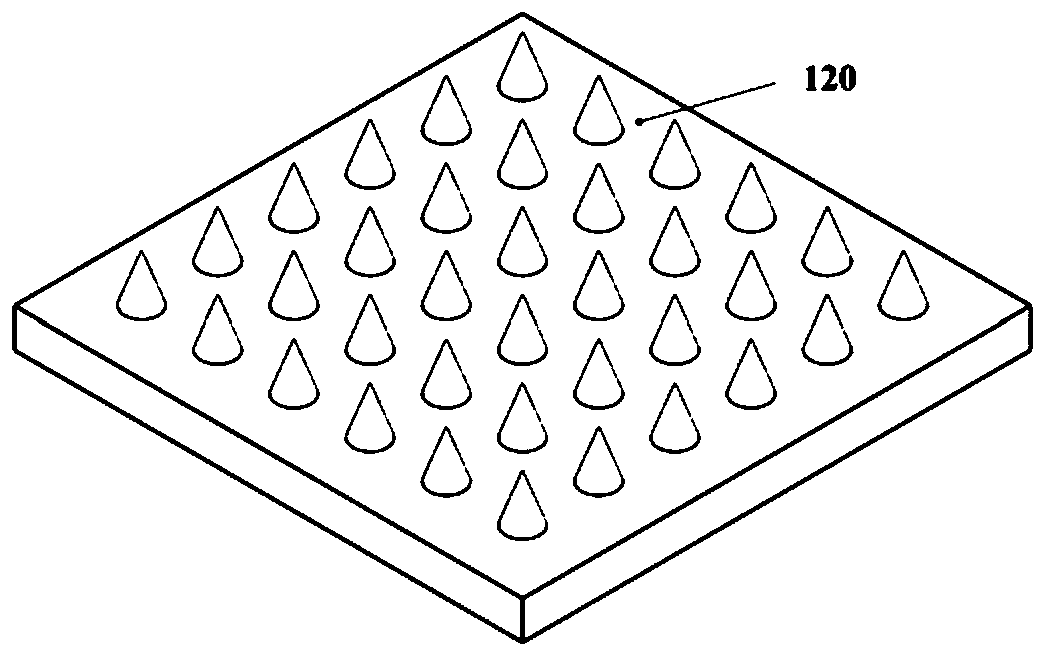

[0056]A number of nano-protruding structures are distributed on the surface of the cured resin layer, and the material is resin doped with nano-silver particles. Nano-silver particles 140 are distributed on the surface of the protruding structures; the shapes of the nano-protruding structures are conical, cylindrical, circular Shapes such as trapezoid, cuboid, prism or prism, the diameter of the nano-protrusion structure is 10nm-500nm, such as 10nm, 20nm, 30nm, 40nm, 50nm, etc., the distance between two adjacent nano-protrusion structures The int...

Embodiment 2

[0059] A preparation system for a flexible surface-enhanced Raman detection substrate, such as Figure 6 shown, including:

[0060] The film substrate traction component provides traction for the movement of the film substrate, and the traction component can be a traction roller powered by a motor;

[0061] Coating device 240, located above the film substrate, with an opening below it, for coating the resin on the film substrate;

[0062] The embossing assembly, located downstream of the coating device, includes two pressure rollers 210 and a mold roller 220, and the mold roller 220 is positioned between the two pressure rollers 210; the surface of the pressure roller 210 is smooth, and the surface of the mold roller 220 is distributed with Nano concave hole, the diameter of the nano concave hole is 10nm-500nm, such as 10nm, 20nm, 30nm, 40nm, 50nm, etc., the shape of the nano concave hole is conical, cylindrical, conical, cuboid, prism or prism body shape.

[0063] The curi...

Embodiment 3

[0067] The gold thin film layer 110 is evenly distributed on the surface of the multi-level nanostructure through the evaporation component 250, so that the multi-level nanostructure is metallized, and the effect of enhancing the Raman scattering signal is generated. The thickness is 15nm.

[0068] The feed speed of the film substrate is 30m / min, and the pressure value between the pressure roller 210 and the mold roller 220 is 4kg / cm 2 , The molding temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com