Pretreatment method for fresh food materials and method for determining amino acid content

A method of determination and amino acid technology, which is applied in the field of pretreatment of fresh food materials, can solve the problems of long amino acid determination time, cumbersome and complicated steps, and increased detection cost, and achieve the effects of shortening pretreatment time, fast heating, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

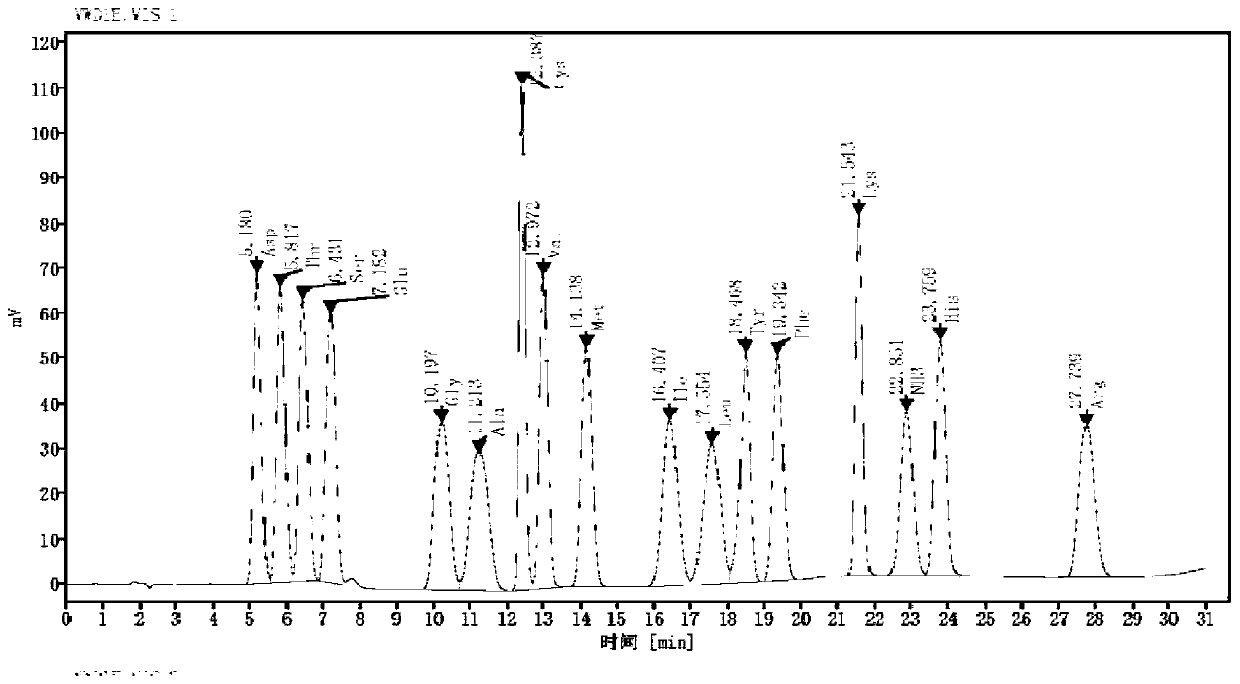

[0065] The samples in this embodiment are taken from frozen beef in fresh meat ingredients.

[0066] A pretreatment method for fresh ingredients, comprising the following steps:

[0067] (a) Sample extraction: Weigh 0.1 g of the ground frozen beef sample, place it in a microwave digestion tank, add 5 ml of 50% hydrochloric acid aqueous solution, then add 30 mg of phenol protective agent, and mix well;

[0068] (b) Microwave hydrolysis: quickly install the microwave digestion tank on the microwave digestion instrument for microwave hydrolysis, set the microwave hydrolysis power to 800W, set the microwave heating program of the microwave digestion instrument, gradually increase from room temperature to 50°C within 4 minutes, and keep at 50°C Continue to heat at ℃ for 10 minutes, adjust the temperature of the microwave digestion instrument so that the temperature rises from 50 to 140 in 3 minutes, keep at 140 and continue heating for 25 minutes for microwave hydrolysis, stop heat...

Embodiment 2

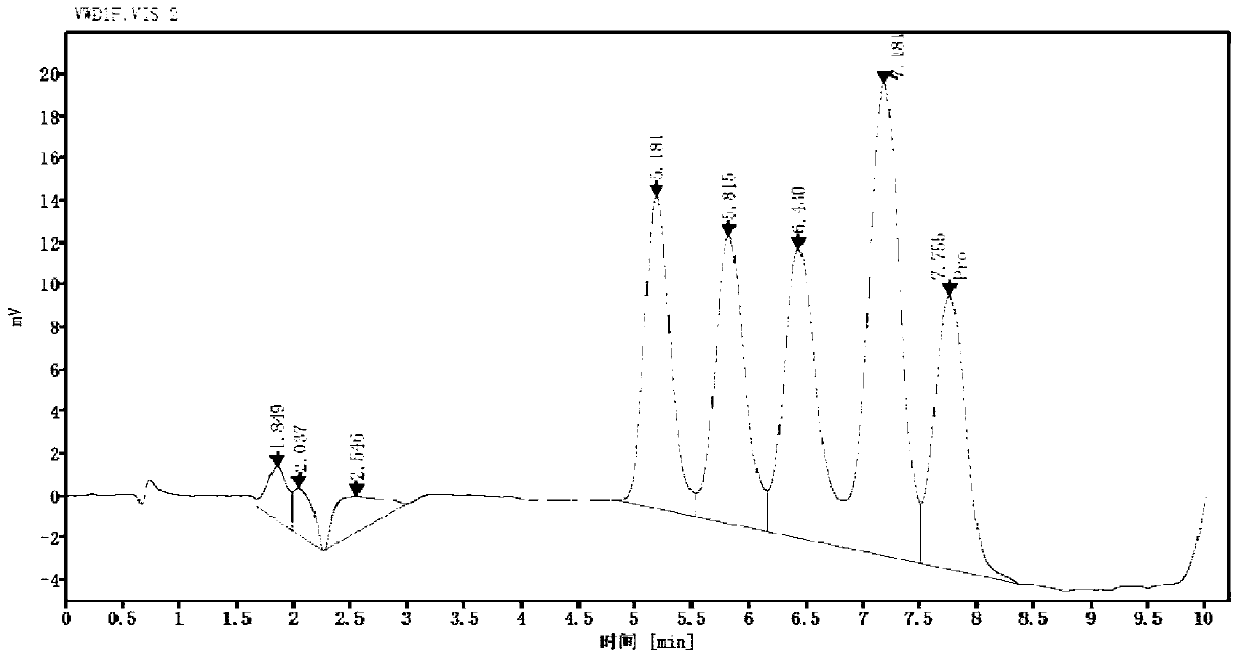

[0110] The samples in this embodiment are taken from turbot in fresh aquatic food materials.

[0111] A pretreatment method for fresh ingredients, comprising the following steps:

[0112] (a) Sample extraction: Weigh 1 g of the ground turbot sample, place it in a microwave digestion tank, add 10 ml of 50% hydrochloric acid aqueous solution, then add 40 mg of phenol protective agent, and mix well;

[0113] (b) Microwave hydrolysis: quickly install the microwave digestion tank on the microwave digestion instrument for microwave hydrolysis, set the microwave hydrolysis power to 1000W, set the microwave heating program of the microwave digestion instrument, gradually increase from room temperature to 60°C within 5 minutes, and keep at 60°C Continue to heat at ℃ for 6 minutes, adjust the temperature of the microwave digestion instrument so that the temperature rises from 60 to 150 in 4 minutes, keep at 150 and continue heating for 20 minutes for microwave hydrolysis, stop heating, ...

Embodiment 3

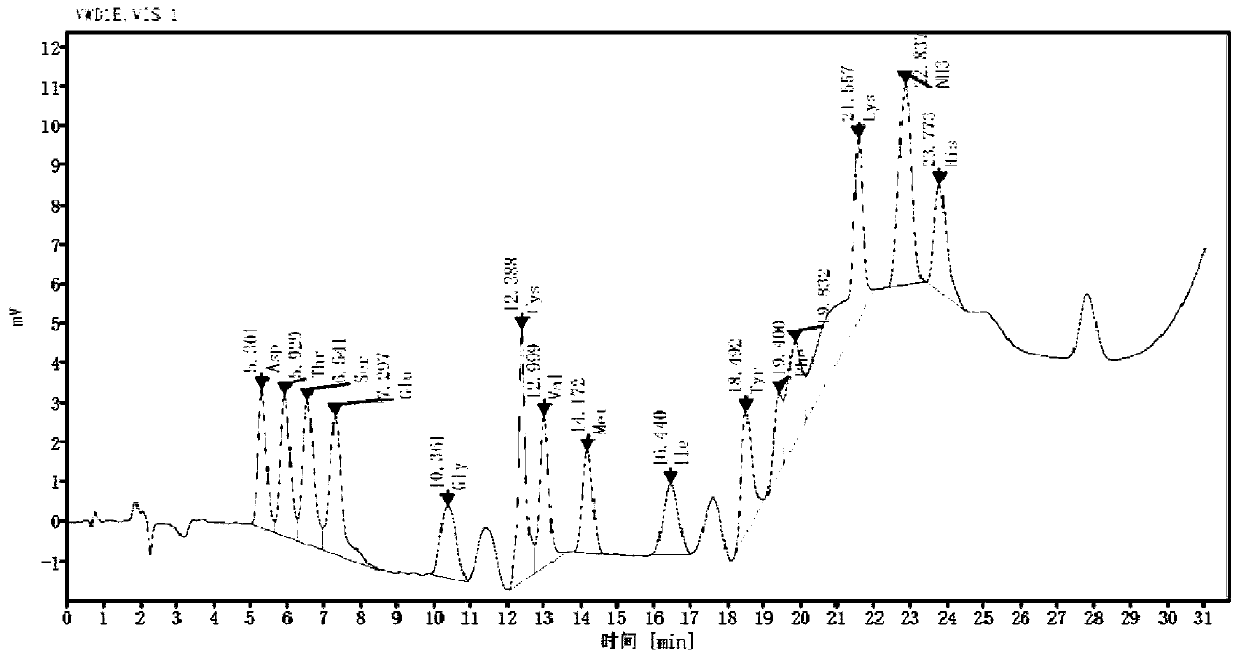

[0158] The samples in this embodiment are taken from eggs in raw egg ingredients.

[0159] A pretreatment method for fresh ingredients, comprising the following steps:

[0160] (a) Sample extraction: take 2 g of stirred egg samples, place them in a microwave digestion tank, add 15 ml of 50% hydrochloric acid aqueous solution, then add 50 mg of phenol protective agent, and mix well;

[0161] (b) Microwave hydrolysis: quickly install the microwave digestion tank on the microwave digestion instrument for microwave hydrolysis, set the microwave hydrolysis power to 1200W, set the microwave heating program of the microwave digestion instrument, gradually increase from room temperature to 70°C within 6 minutes, and keep at 70°C Continue heating at ℃ for 3 minutes, adjust the temperature of the microwave digestion instrument so that the temperature rises from 70°C to 160°C within 5 minutes, keep at 160°C and continue microwave hydrolysis heating for 15 minutes, stop heating, and when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com