Inorganic nanoparticle-modified aramid fiber paste and aramid-coated lithium battery composite diagram

A technology of inorganic nanoparticles and modified aramid fiber, which is applied in the direction of nanotechnology, nanotechnology, battery pack components, etc., and can solve the problem of limited improvement in high temperature resistance, poor heat resistance and mechanical properties of lithium battery separators, and aramid fibers The coating affects the air permeability and other issues, and achieves the effects of good processability, improved wettability, and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

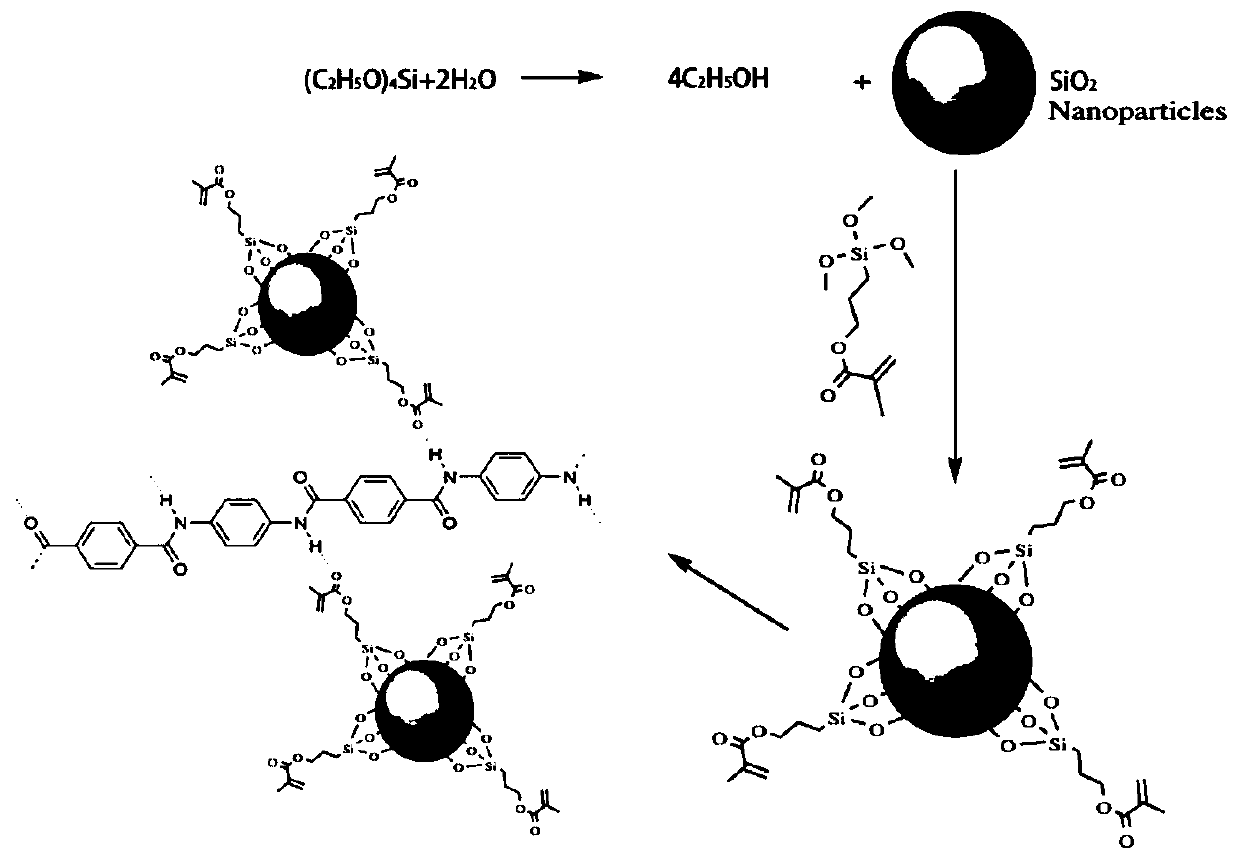

[0046] One, the synthesis of silica nanoparticle modified aramid fiber slurry (such as figure 1 shown):

[0047] (1) Ethyl tetrasilicate and ethanol are reacted under the environment of PH=4 with the ratio of 1:1 to obtain silica nanoparticles; the synthesized silica nanoparticles are poured into dimethylacetamide , then add 1wt% silane coupling agent (KH-570), and react at room temperature for 24h to obtain silica nanoparticles modified by the coupling agent;

[0048](2) under room temperature condition, in reactor, add dimethylacetamide / calcium chloride solvent, pass into nitrogen, and stir, add the silica nanoparticle ( 2wt%), while adding p-phenylenediamine powder, so that the concentration of p-phenylenediamine is 8mg / mL;

[0049] (3) Lower the temperature of the reactor to about 0°C, and stir vigorously, then add 8.1 mg / mL terephthaloyl chloride powder, and continue stirring at high speed for 10 minutes, then add calcium hydroxide to make the pH of the synthesis soluti...

Embodiment 2

[0056] The difference between this embodiment and Example 1 is that the inorganic nanoparticles are titanium dioxide; in the titanium dioxide nanoparticle modified aramid fiber slurry, the aramid fiber percentage is 2.5wt%, and the titanium dioxide nanoparticle percentage is 3wt%. The percentage content of the joint agent is 1.5wt%.

Embodiment 3

[0058] The difference between this example and Example 1 is that the inorganic nanoparticles are magnesium oxide; in the magnesium oxide nanoparticle modified aramid slurry, the aramid fiber percentage is 5wt%, and the magnesium oxide nanoparticle percentage is 10wt%. , the percentage content of coupling agent is 2wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com