Fan blade cleaning system for aircraft engine

An aircraft engine and fan blade technology, applied in mechanical conveyors, conveyors, cleaning methods and utensils, etc., can solve the problems of aggravating aircraft engine blade corrosion, high labor intensity, long working hours, etc., to protect workers' health and save money. Labor cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

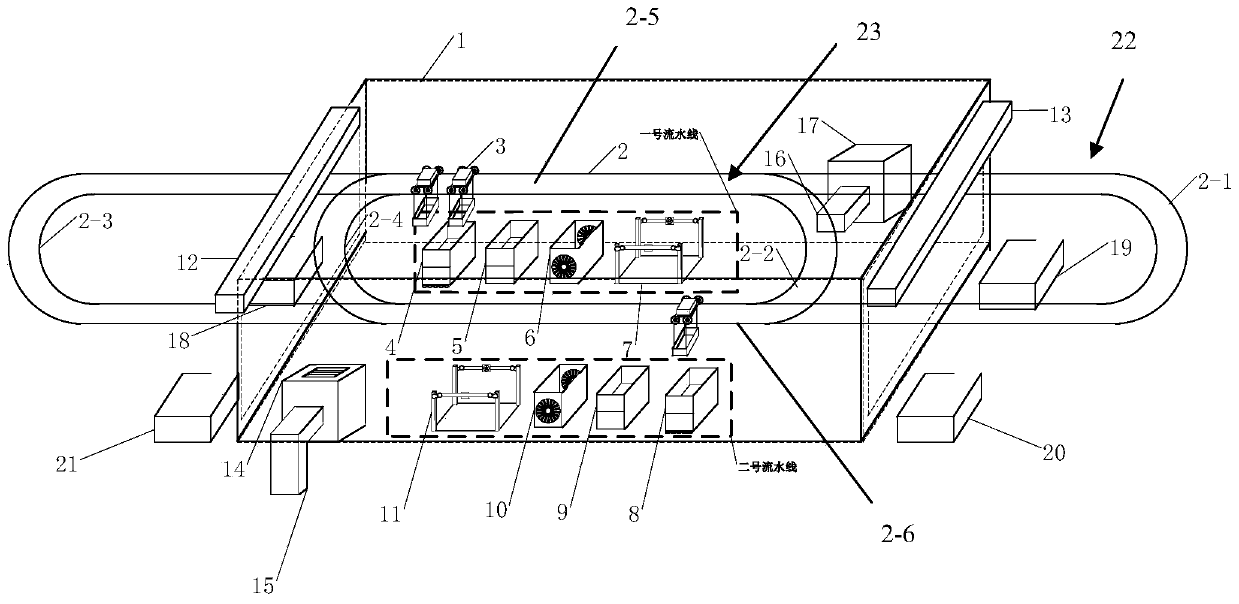

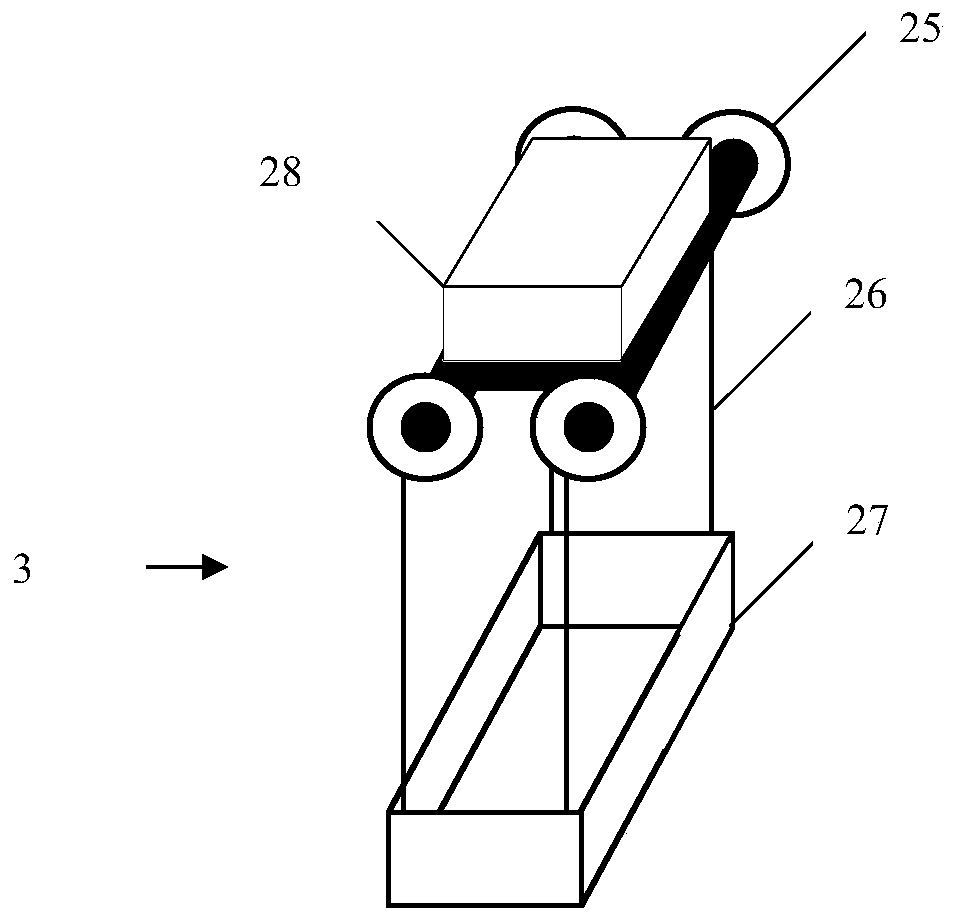

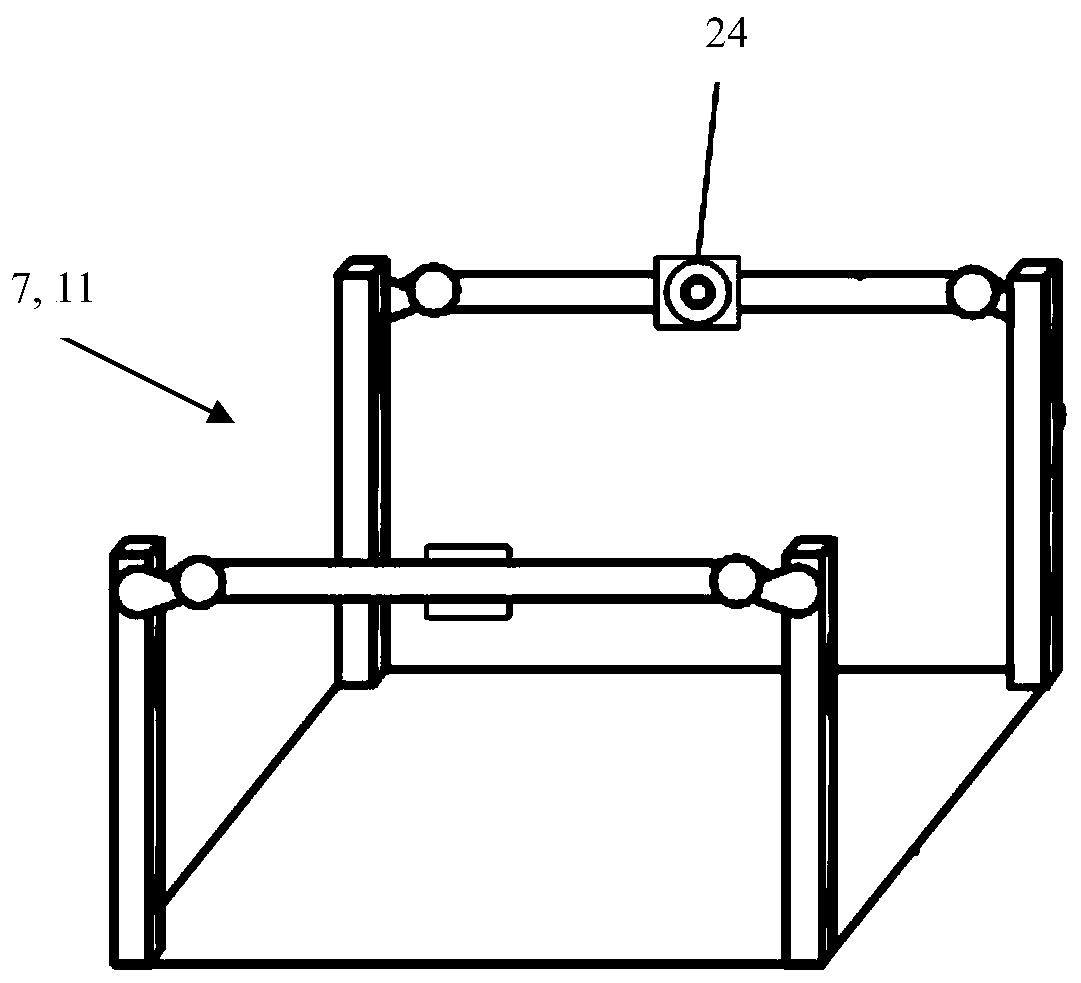

[0021] Such as figure 1 As shown, the aircraft engine fan blade cleaning system provided by the present invention includes a casing 1, a pulley track 2, a loading electric rail car 3, a first air curtain machine 12, a second air curtain machine 13, a blower fan 14, a gas filtering device 17, No. 1 assembly line and No. 2 assembly line; wherein, the housing 1 is a cuboid structure, and the front and rear ends are open; the first air curtain machine 12 and the second air curtain machine 13 are respectively installed on the upper part of the front and rear ports of the housing 1; the pulley The track 2 is composed of a long loop track 22 and a short loop track 23. The long loop track 22 and the short loop track 23 are elongated circular structures, and the two side tracks of the short loop track 23 are connected with the two sides of the long lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com