Nano antibacterial hemp fibers and preparation method and application thereof

An antibacterial hemp and fiber-like technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of decreased antibacterial effect and inconspicuous antibacterial effect, achieve good dispersion and uniformity, realize antibacterial performance and resistance The effect of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Extraction of cannabis leaf plant extract

[0032] (1) Ultrasonic extraction of crushed marijuana flowers and leaves at room temperature (15-30°C) with methanol at a solid-to-liquid ratio of 1g:15mL (or 1:20 or 1:25), the ultrasonic extraction power is 90-110W, and the ultrasonic time 8-12min, then stand at room temperature for 50-100min, centrifuge at 3000-5000rpm for 4-6min, take the supernatant, and obtain the plant extract.

[0033] (2) Use ethanol with a solid-to-liquid ratio of 1g:15mL (or 1:20 or 1:25) to conduct ultrasonic extraction at room temperature (15-30°C) on the crushed cannabis flowers and leaves. The ultrasonic extraction power is 90-110W, and the ultrasonic time 8-12min, then stand at room temperature for 50-100min, centrifuge at 3000-5000rpm for 4-6min, take the supernatant, and obtain the plant extract.

[0034] (3) The crushed marijuana flowers and leaves are treated at room temperature (15-30° C. ) ultrasonic extraction, the ultras...

Embodiment 2

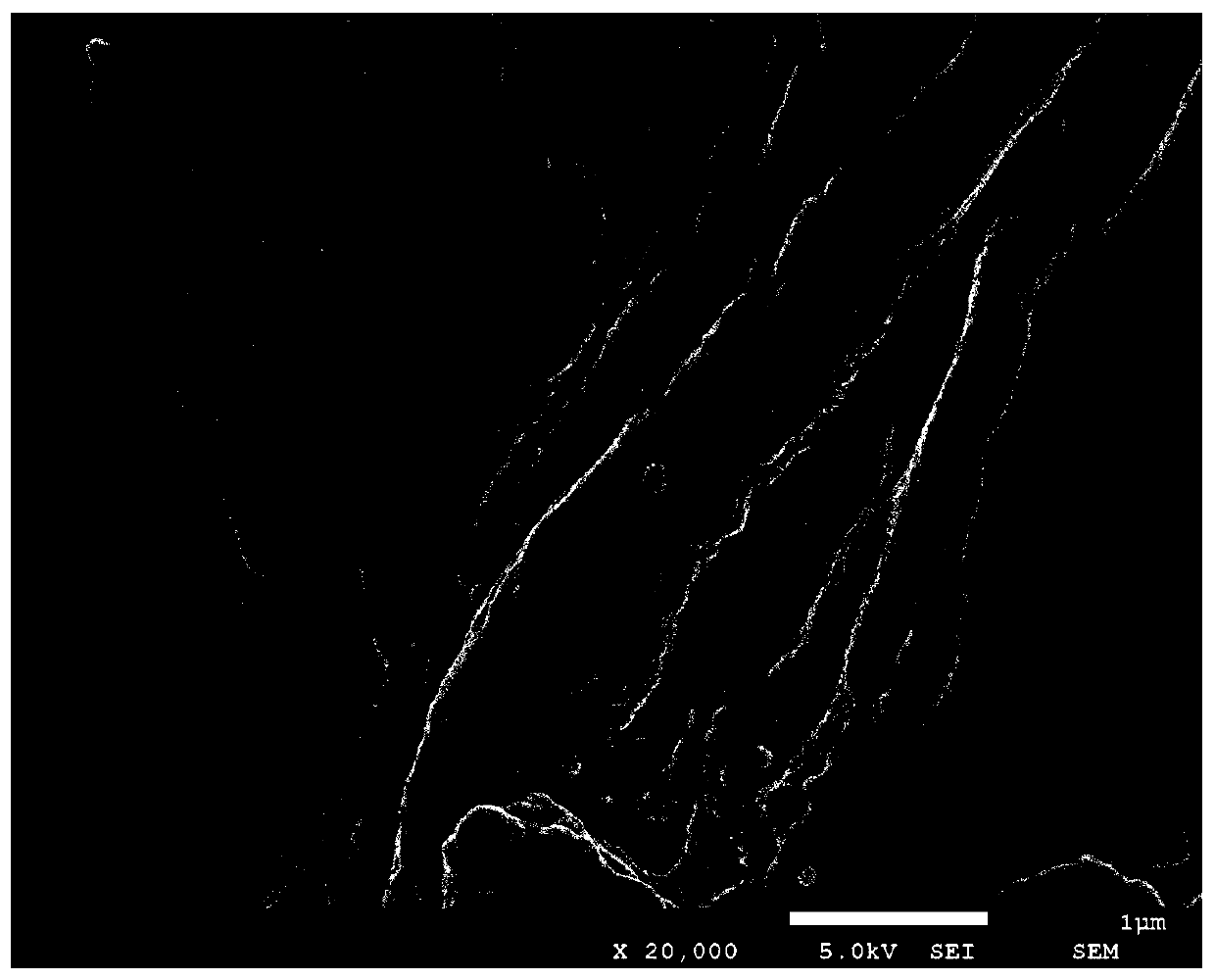

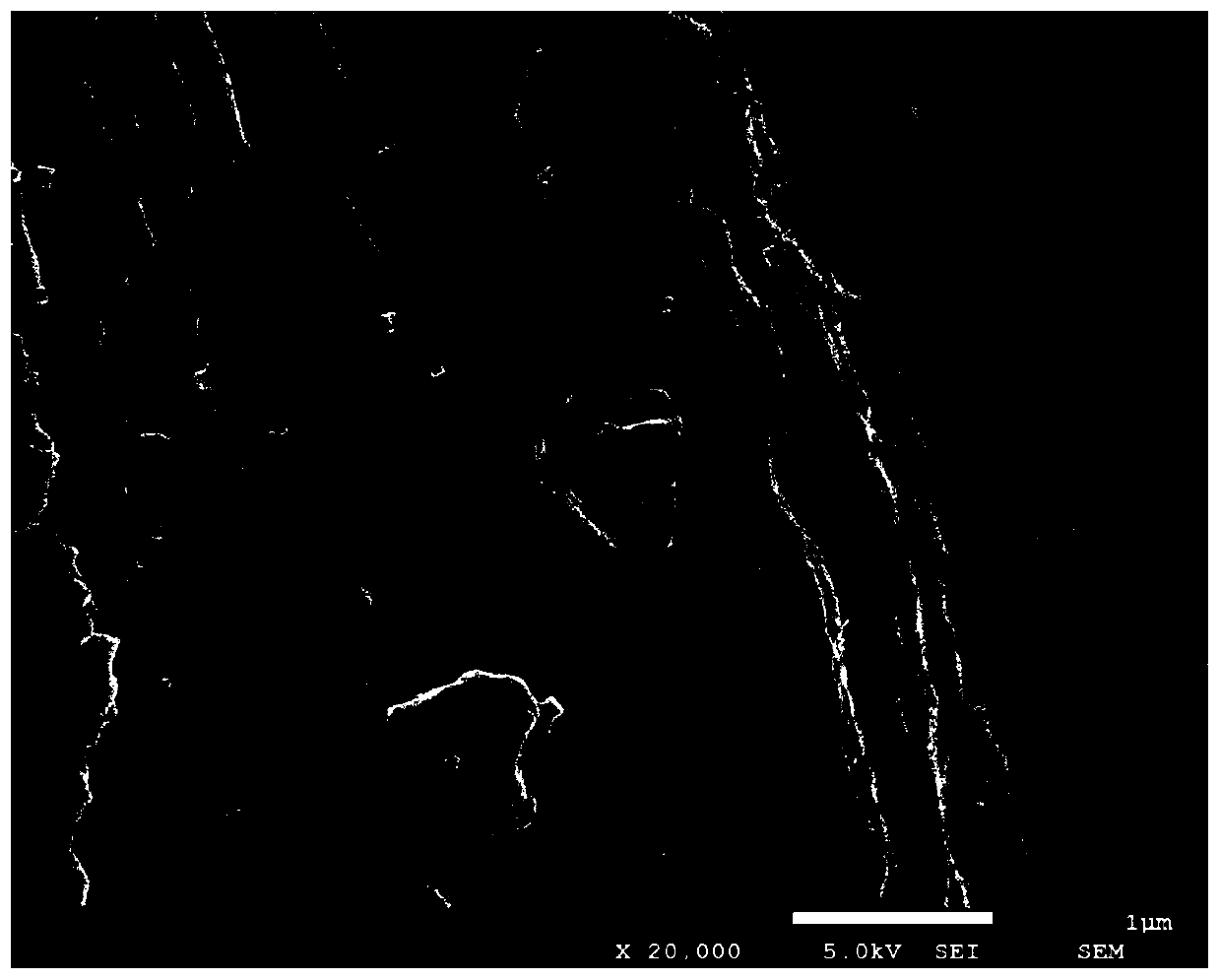

[0035] Embodiment 2: Preparation of nano antibacterial hemp fiber

[0036] Take 0.2g industrial hemp fiber, soak it in 20mL silver nitrate solution of 0.01-0.1mol / L, and place it at room temperature for 1-24h to make the fiber absorb silver ions;

[0037]Take out the fiber and squeeze it dry, put it into 20mL of distilled water, and place it in a water bath shaking box at 30-70°C. When the reaction system rises to 30-70°C, add 1-5mL of the plant extract in Example 1 , continue to react for 0.5-24h.

[0038] The fibers were taken out, washed with distilled water, and placed in an oven at 40°C until constant weight.

Embodiment 3

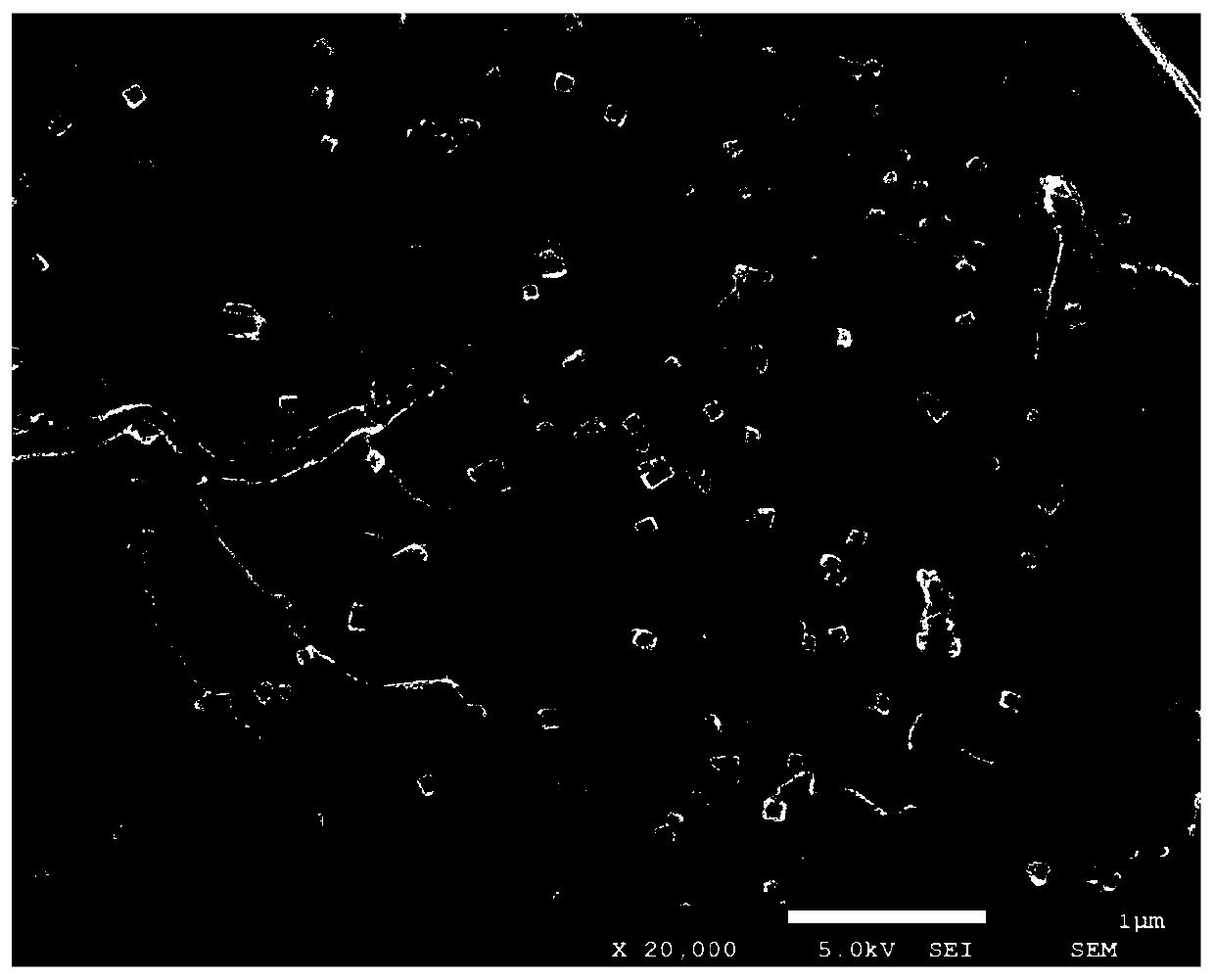

[0039] Example 3: Detection of the short-term antibacterial performance and wash-out resistance of the nano-antibacterial hemp fiber

[0040] Prepare contrast antibacterial industrial hemp fiber according to the method of embodiment 2, just select conventional sodium borohydride reducing agent, group into industrial hemp fibril+AgNO 3 +NaBH 4 ; Only soak industrial hemp fibrils with silver nitrate solution to prepare silver ion adsorption type contrast antibacterial industrial hemp fibers, grouped as industrial hemp fibrils+AgNO 3 ;

[0041] The antibacterial industrial hemp fiber prepared in Example 2 for the nano-hemp antibacterial fiber of the present invention is different in that one uses methanol to extract industrial hemp flowers and leaves, and the other uses ethanol to extract industrial hemp flowers and leaves, and is grouped into industrial hemp fibrils+AgNO 3 +Plant extract (methanol) and industrial hemp fibrils+AgNO 3 +Plant extract (ethanol);

[0042] Evaluat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com