Co-injection-molded multilayer structure

一种多层结构体、共注射的技术,应用在合成树脂层状产品、分层产品、包装物品类型等方向,能够解决EVOH层与疏水性树脂层粘接性差、制造成本上升等问题,达到层间粘接性优异、优异粘接性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

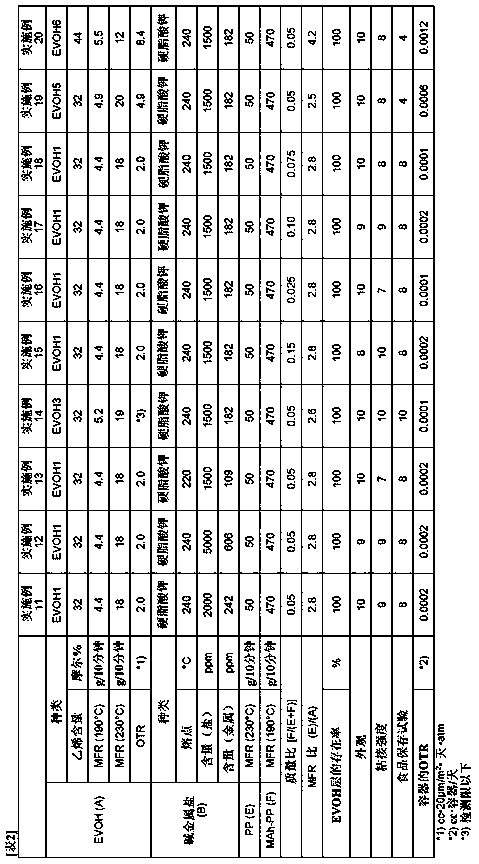

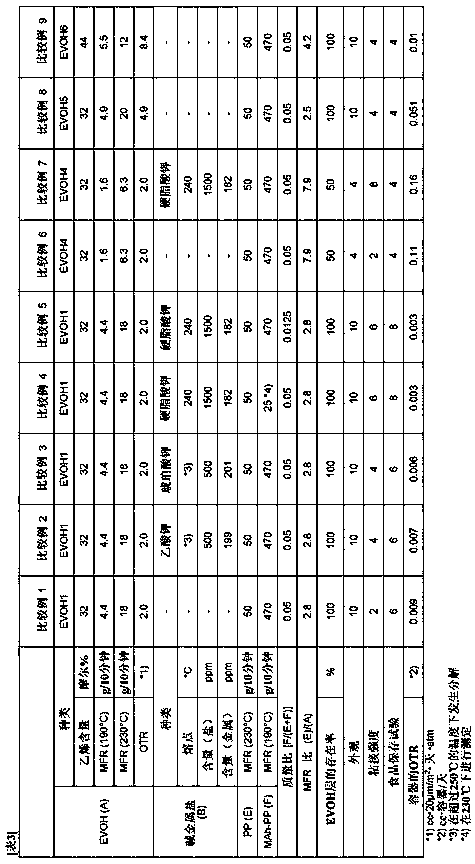

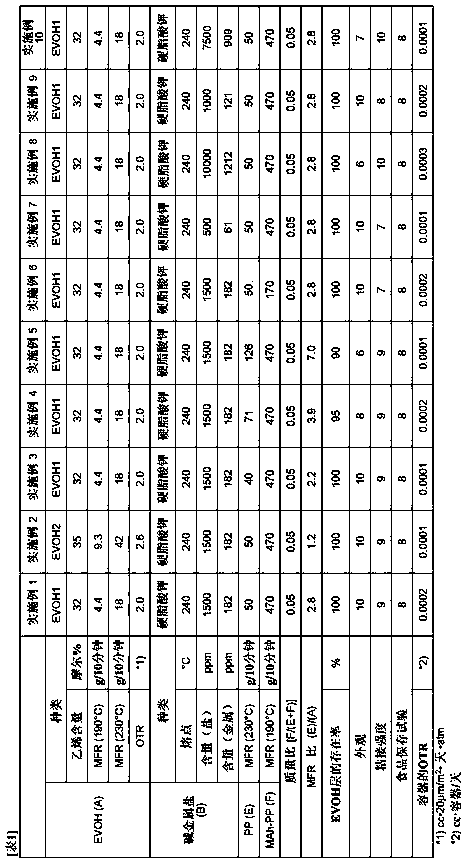

Embodiment 1

[0126] For an ethylene content rate of 32 mol%, saponification degree of 99 mol% or more, MFR of 4.4g / 10min (190°C, 2160g load), OTR of 2.0cc・20μm / m 2 ・Day・atm (20℃ / 85%RH) EVOH resin (Curare Co., Ltd. エバール F104B) (called "EVOH1") mixed with 1500ppm of potassium stearate (based on 182 ppm in terms of metal atoms), melt-kneading, pelletization, and drying were performed under the following conditions to obtain pellets of the EVOH resin composition. Potassium stearate has a melting point of 240°C.

[0127] ・Equipment: 26mmφ twin-screw extruder (by Toyo Seiki Seisakusho, ラボプラストミル15C300)

[0128] ・L / D: 25

[0129] ・Screw: Full engagement in the same direction

[0130] ・Number of die holes: 2 holes (3mmφ)

[0131] ・Extrusion temperature (°C): C1=200, C2~C5=240, Die=240

[0132] ・Rotation speed: 100rpm

[0133] ・Discharge amount: about 5kg / hr

[0134]・Drying: hot air drying 80℃ / 6hr

[0135] Using the obtained pellets of the EVOH resin composition, a film was formed under the ...

Embodiment 2

[0162] Instead of EVOH1, use an ethylene content of 35 mol%, a saponification degree of 99 mol% or more, an MFR of 9.3g / 10min (190°C, 2160g load), and an OTR of 2.6cc・20μm / m 2 ・Day・atm (20°C / 85%RH) EVOH resin (Eval C109B manufactured by Kurare Co., Ltd.) (called "EVOH2") was obtained by the same method as in Example 1. EVOH resin composition, Hybrid polypropylene pellets, monolayer films and co-injection molded multilayer structures. The obtained single-layer film and co-injection molded multilayer structure were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0164] An EVOH resin composition was obtained by the same method as in Example 1 except that MOPLEN RP398T (MFR=40g / 10min (230°C, 2160g load)) manufactured by Lyondell Basell was used as the polypropylene (E). , mixed polypropylene pellets, monolayer films and co-injection molded multilayer structures. The obtained single-layer film and co-injection molded multilayer structure were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com