A kind of white expansion agent for decorating concrete and preparation method thereof

A technology for decorative concrete and expansion agent, applied in the field of white expansion agent, can solve the problems of not being able to compensate for shrinkage cracking of decorative concrete, low whiteness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

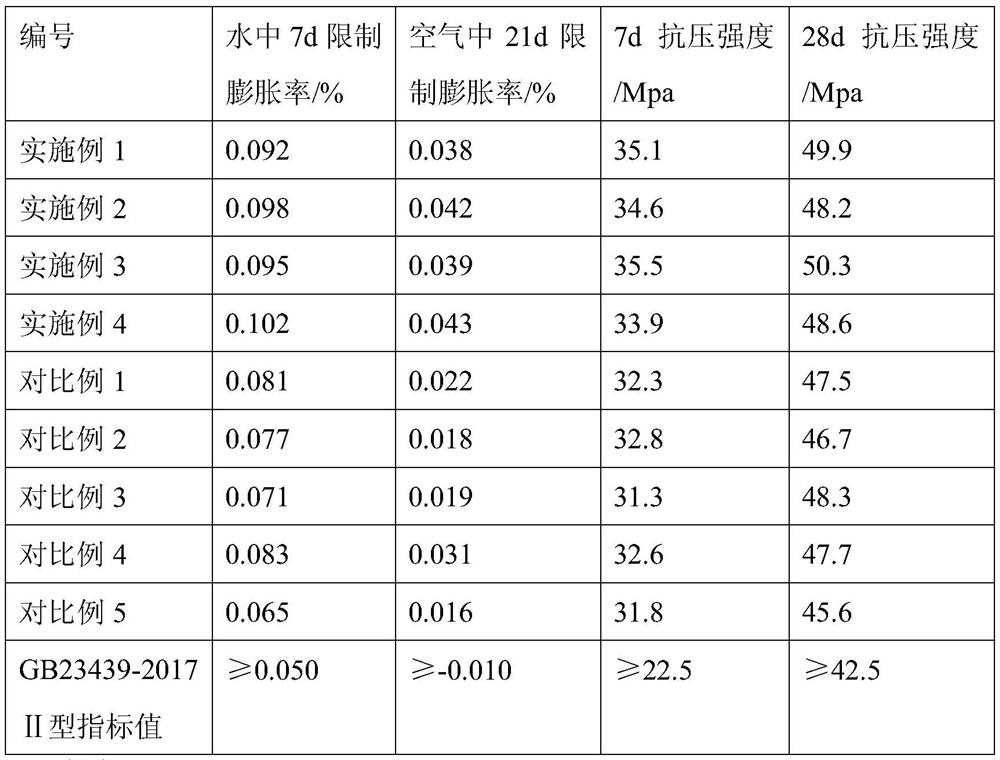

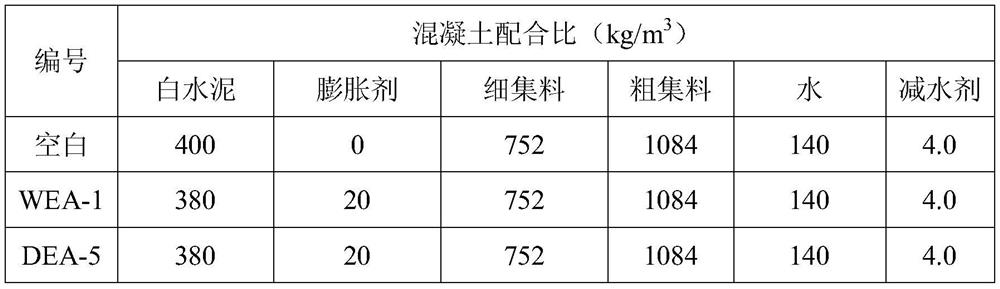

Examples

Embodiment 1

[0019] First, 60 parts of low-iron high-calcium limestone, 40 parts of mold gypsum and 2 parts of composite mineralizer are mixed in proportion and then ground into raw meal powder with a fineness of 250 mesh, wherein the composite mineralizer has a mass fraction of 40 % calcium chloride and 60% barium sulfate; the raw meal powder is calcined at high temperature in a rotary kiln with petroleum coke as fuel, the calcining temperature is set at 1250°C, and the calcining time is set at 90 minutes, and calcined in the rotary kiln The fired clinker is unloaded from the kiln head, and is rapidly air-cooled by a single-tube cooler to obtain expanded clinker; finally, the expanded clinker is ground to a specific surface area of 350m 2 / kg, a kind of white expansion agent embodiment WEA-1 for compensating decorative concrete of the present invention is obtained.

Embodiment 2

[0021] First, 65 parts of low-iron and high-calcium limestone, 35 parts of mold gypsum and 2 parts of composite mineralizer are mixed in proportion and then ground into raw meal powder with a fineness of 280 meshes, wherein the composite mineralizer has a mass fraction of 50 % calcium chloride and 50% barium sulfate; the raw meal powder is calcined at high temperature in a rotary kiln with petroleum coke as fuel, the calcining temperature is set at 1300°C, and the calcining time is set at 75 minutes, and then calcined in a rotary kiln The fired clinker is unloaded from the kiln head, and is rapidly air-cooled by a single-tube cooler to obtain expanded clinker; finally, the expanded clinker is ground to a specific surface area of 325m 2 / kg, a kind of white expansion agent embodiment WEA-2 for compensating decorative concrete of the present invention is obtained.

Embodiment 3

[0023] First, 70 parts of low-iron and high-calcium limestone, 30 parts of mold gypsum and 3 parts of composite mineralizer are mixed in proportion and then ground into raw meal powder with a fineness of 300 mesh, wherein the composite mineralizer has a mass fraction of 55 % calcium chloride and 45% barium sulfate; the raw meal powder is calcined at high temperature in a rotary kiln with petroleum coke as fuel, the calcining temperature is set at 1350°C, and the calcining time is set at 60 minutes, and calcined in the rotary kiln The fired clinker is unloaded from the kiln head, and is rapidly air-cooled by a single-tube cooler to obtain expanded clinker; finally, the expanded clinker is ground to a specific surface area of 300m 2 / kg, a kind of white expansion agent embodiment WEA-3 for compensating decorative concrete of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com