Polycarboxylic acid water reducing agent special for precast concrete and preparation technology thereof

A prefabricated component and preparation process technology, applied in the field of polycarboxylate water reducing agent, can solve the problems of reduced compressive strength ratio, increased cost, long concrete setting time, etc., and achieves improved early strength, clever design, and accelerated hydration hardening effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

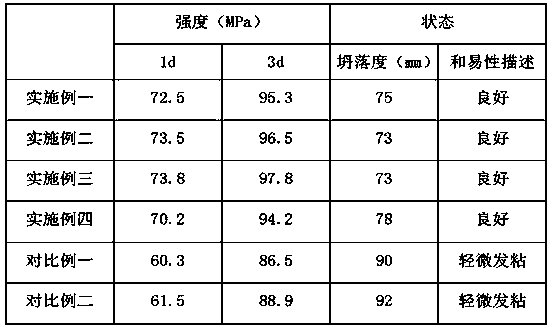

Examples

Embodiment 1

[0023] The special polycarboxylate water reducer for prefabricated component concrete proposed by the present invention is composed of the following raw materials in parts by weight: 300 parts of polyether macromonomer, 35 parts of methacrylic acid, 3.5 parts of chain transfer agent, and 8 parts of unsaturated monocarboxylic acid , 3 parts of unsaturated amphoteric quaternary phosphorus salt, 2.5 parts of calcium sulfate, 1.0 part of sodium sulfate, 1.5 parts of reducing agent, 1.0 part of oxidizing agent, 0.50 parts of vitamin C waste mother liquor, 10 parts of liquid caustic soda, appropriate amount of deionized water.

[0024] The preparation process of the special polycarboxylate water reducer for prefabricated component concrete proposed by the present invention comprises the following steps,

[0025] S1, weighing each raw material component by weight;

[0026] S2, dissolving methacrylic acid and chain transfer agent in 30 parts by weight of deionized water, and adjusting...

Embodiment 2

[0031] The polycarboxylate superplasticizer for prefabricated component concrete proposed by the present invention is composed of the following raw materials in parts by weight: 310 parts of polyether macromonomer, 37 parts of methacrylic acid, 4.5 parts of chain transfer agent, and 11.5 parts of unsaturated monocarboxylic acid , 11 parts of unsaturated amphoteric quaternary phosphorus salt, 3.5 parts of calcium sulfate, 1.5 parts of sodium sulfate, 2 parts of reducing agent, 2 parts of oxidizing agent, 0.60 part of vitamin C waste mother liquor, 15 parts of liquid caustic soda, appropriate amount of deionized water.

[0032] The preparation process of the special polycarboxylate water reducer for prefabricated component concrete proposed by the present invention comprises the following steps,

[0033] S1, weighing each raw material component by weight;

[0034] S2, dissolving methacrylic acid and chain transfer agent in 32 parts by weight of deionized water, and adjusting the...

Embodiment 3

[0039] The polycarboxylate superplasticizer for prefabricated component concrete proposed by the present invention is composed of the following raw materials in parts by weight: 310 parts of polyether macromonomer, 37 parts of methacrylic acid, 4.5 parts of chain transfer agent, and 11.5 parts of unsaturated monocarboxylic acid , 11 parts of unsaturated amphoteric quaternary phosphorus salt, 3.5 parts of calcium sulfate, 1.5 parts of sodium sulfate, 2 parts of reducing agent, 2 parts of oxidizing agent, 0.60 part of vitamin C waste mother liquor, 15 parts of liquid caustic soda, appropriate amount of deionized water.

[0040] The preparation process of the special polycarboxylate water reducer for prefabricated component concrete proposed by the present invention comprises the following steps,

[0041] S1, weighing each raw material component by weight;

[0042] S2, dissolving methacrylic acid and chain transfer agent in 33 parts by weight of deionized water, and adjusting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com