Method for simultaneous desulfurization and denitrification of dry flue gas

A technology for desulfurization and denitrification and flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as high operating costs, increased resistance of desulfurization and denitrification equipment, and difficulty in removing NO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

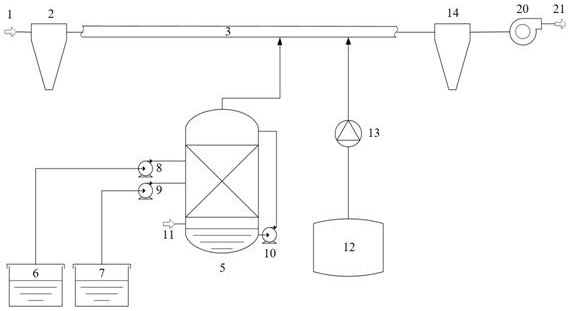

[0046] Embodiment 1: as figure 1 As shown, the method of simultaneous desulfurization and denitrification of flue gas in this dry process is as follows:

[0047] A coke oven in an iron and steel enterprise, the exhaust gas contains nitrogen oxides, sulfur dioxide, and dust, of which the average concentration of NO is 320mg / Nm³, NO 2 The average concentration is about 30mg / Nm³, NO x The concentration can reach 1000mg / Nm instantaneously 3 ;SO 2 The average concentration of about 110mg / Nm 3 ;The dust content of flue gas is about 1000mg / Nm 3 ; The flue gas temperature is 220°C.

[0048] (1) Flue gas pretreatment: the flue gas 1 is collected by the flue gas header 3 lined with Teflon, and the Teflon coating can work for a long time in a high temperature environment of 250 ° C; Soot content about 5mg / Nm 3 , the removal rate of dust with a particle size ≥ 25 μm is 99.9%;

[0049] (2) ClO 2 Preparation of gas: ClO 2 Generating device 5 adopts a packing type circulating spray...

Embodiment 2

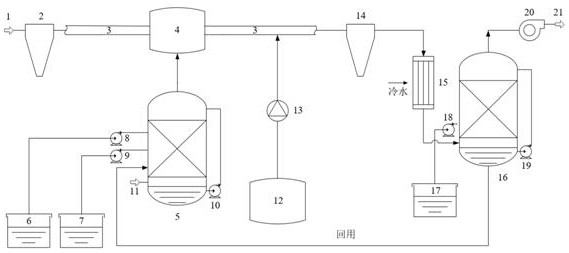

[0058] Embodiment 2: as figure 2 As shown, the method of simultaneous desulfurization and denitrification of flue gas in this dry process is as follows:

[0059] The sintering flue gas of an iron and steel enterprise contains nitrogen oxides, sulfur dioxide, HCl, and dust in the flue gas. The average concentration of NO is 300mg / Nm³, and the NO 2 The average concentration is about 20mg / Nm³; SO 2 The average concentration of about 300mg / Nm 3 ; HCl concentration about 50mg / Nm 3 ;The dust content of flue gas is about 4000mg / Nm 3 , the flue gas temperature is 180 ℃;

[0060] (1) Flue gas pretreatment: the flue gas 1 is collected by the flue gas header 3 lined with Teflon, and the Teflon coating can work for a long time in a high temperature environment of 250°C; the dust is firstly removed by the bag filter 2, and the dust is removed After the dust content is about 10mg / Nm 3, the removal rate of dust with a particle size ≥ 25 μm is 99.0%;

[0061] (2) ClO 2 Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com