Mold-proof and waterproof underground engineering waterproof decorative finish mortar

A facing mortar and underground engineering technology, applied in the field of building materials, can solve the problems that affect the hygiene and safety of the living environment, cannot solve the problem of water seepage on the wall, and are easy to crack and peel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

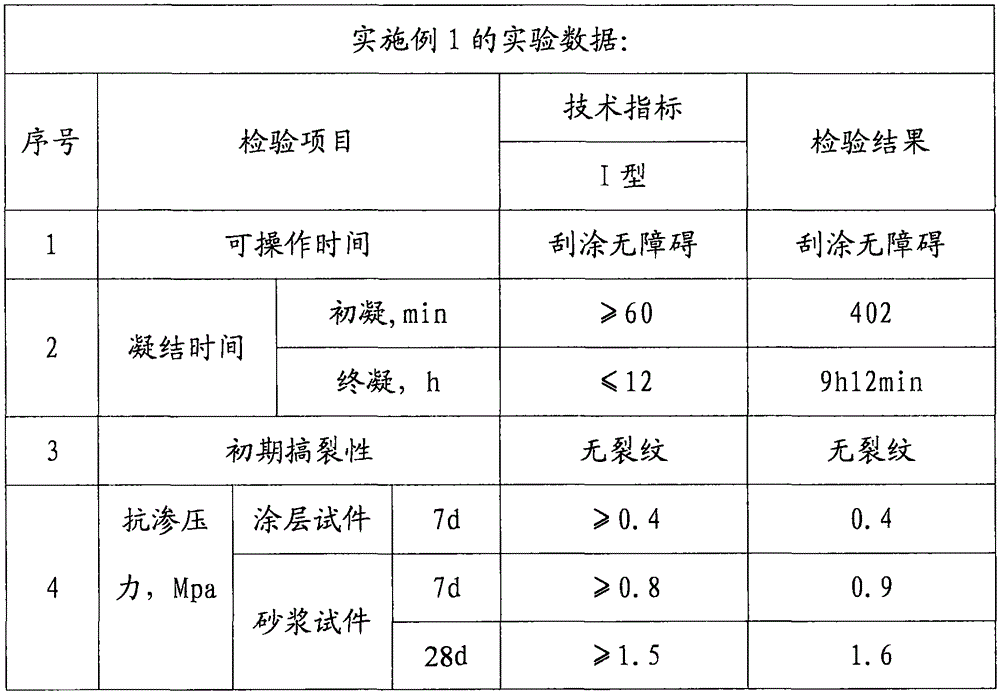

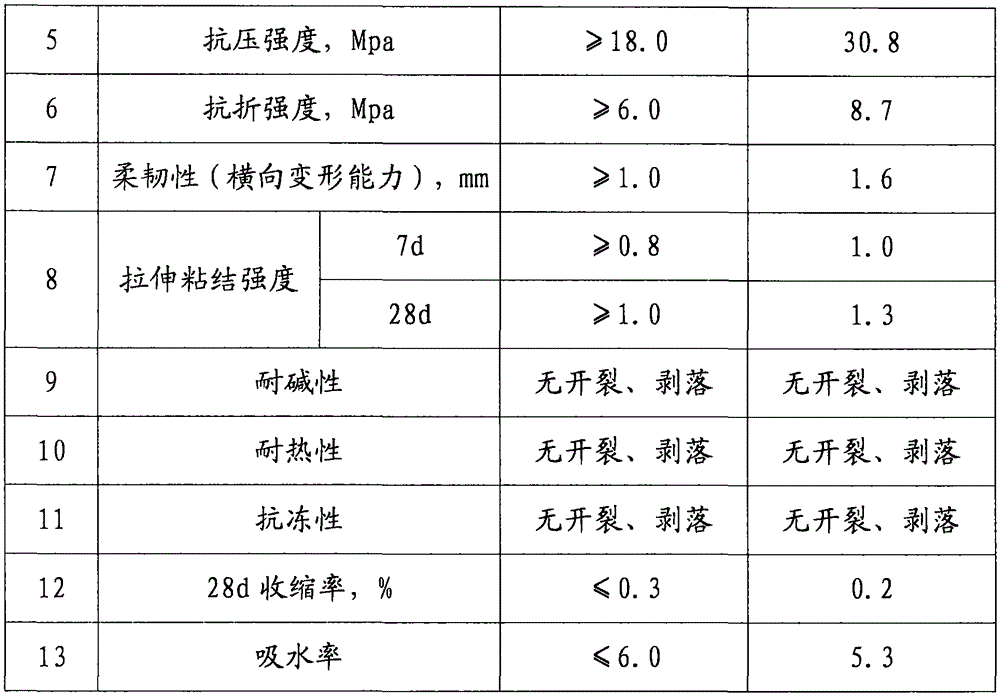

Embodiment 1

[0025] Main material: auxiliary material is 98:2

[0026] Wherein by weight percentage, main material includes

[0027] Cement 35%

[0028] Quartz sand 65%

[0029] Wherein by weight percentage, auxiliary materials include

[0031] Silica 1.5%

[0034] Copper acetate monohydrate 0.01%

[0035] Sodium α-olefin sulfonate 0.01%

[0036] Titanium dioxide 1.2%

[0037] Alum 0.12%

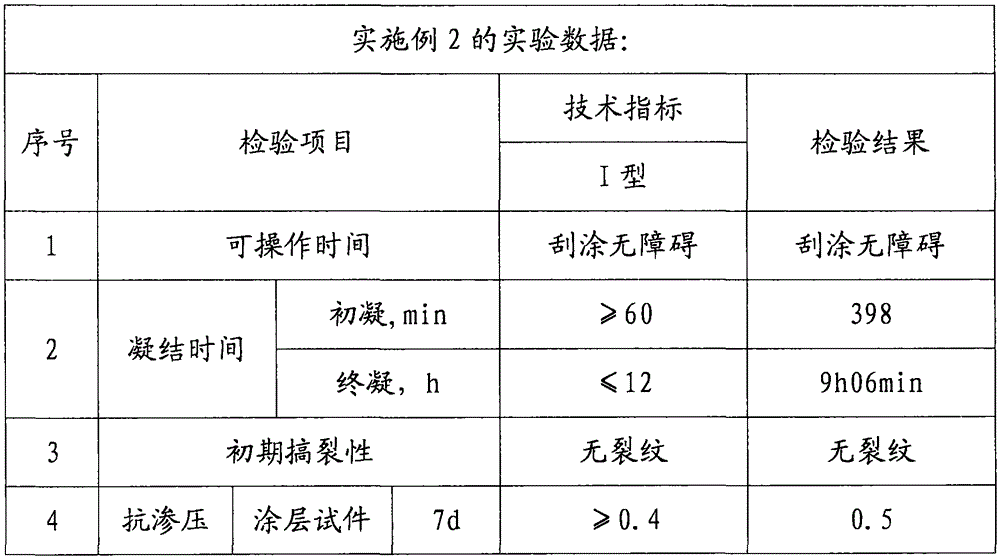

Embodiment 2

[0039] Main material: auxiliary material is 96:4

[0040] Wherein by weight percentage, main material includes

[0041] Cement 38%

[0042] Quartz sand 62%

[0043] Wherein by weight percentage, auxiliary materials include

[0045] Silica 1.8%

[0047] Calcium Carbonate 1.8%

[0048] Copper acetate monohydrate 0.015%

[0049] Sodium α-olefin sulfonate 0.015%

[0050] Titanium dioxide 1.5%

[0051] Alum 0.16%

Embodiment 3

[0053] Main material: auxiliary material is 95:5

[0054] Wherein by weight percentage, main material includes

[0055] Cement 45%

[0056] Quartz sand 55%

[0057] Wherein by weight percentage, auxiliary materials include

[0058] Calcium Stearate 0.8%

[0059] Silica 2%

[0060] Sodium Sulfate 0.2%

[0061] Calcium Carbonate 2%

[0062] Copper acetate monohydrate 0.02%

[0063] Sodium α-olefin sulfonate 0.02%

[0064] Titanium dioxide 1.8%

[0065] Alum 0.2%

[0066] In the above examples, cement is No. 425 Portland cement, and quartz sand is 100 mesh quartz sand

[0067]

[0068]

[0069]

[0070]

[0071]

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com