Automatic continuous testing device and method for coal and rock permeability under non-equilibrium state

A test device and permeability technology, which is applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of reservoir permeability change, low permeability of sample matrix, and influence on gas production, etc. Achieve the effects of avoiding leakage, suitable for long-term continuous measurement, and ensuring control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

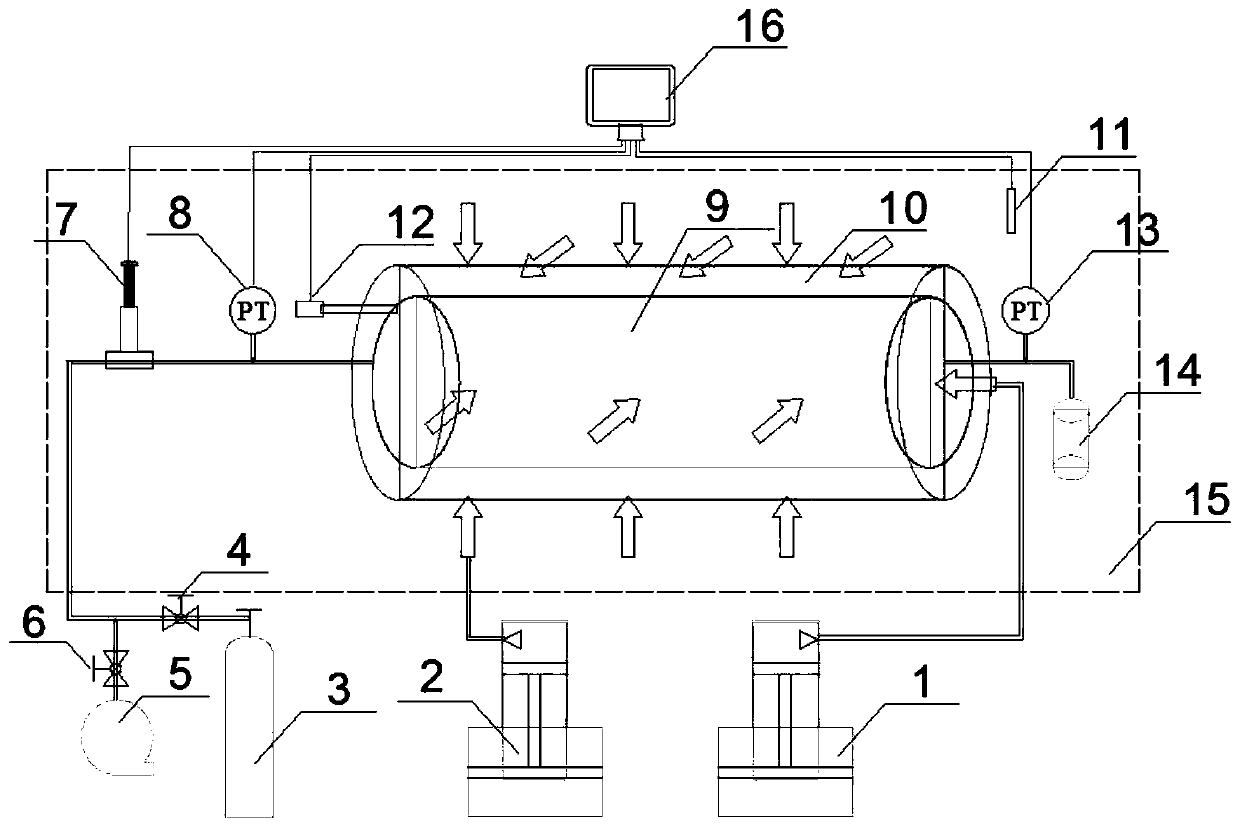

[0071] The simulation test of the gas injection reservoir process includes the following steps:

[0072] ① Process the coal or rock sample into a cylinder with a diameter of 50mm and a height of 100mm, put it in a drying box, and dry it for 24 hours; weigh the sample;

[0073] ②First put the sample into the holder 9 wrapped with the rubber sleeve 10, connect the pipeline to the axial pressure plunger loading pump 1 and the ring pressure plunger loading pump 2, and check the displacement sensor 12, temperature sensor 11, pressure sensor I8, pressure Working state of sensor II13;

[0074] ③ Apply a pressure of 10 MPa to the sample through the axial plunger loading pump 1 and the ring pressure plunger loading pump 2, and check whether there is liquid leakage; set the temperature inside the thermostat 15 to be stable at 25°C, and feed back the data to the data acquisition computer through the temperature sensor 11 16. Automatically adjust the temperature in the incubator 15 throu...

Embodiment 2

[0082] The simulation test of the reservoir gas production process includes the following steps:

[0083] ① Process the coal or rock sample into a cylinder with a diameter of 50mm and a height of 100mm, put it in a drying box, and dry it for 24 hours; weigh the sample;

[0084] ②First put the sample into the holder 9 wrapped with the rubber sleeve 10, and check the working status of the displacement sensor 12, temperature sensor 11, pressure sensor I8, and pressure sensor II13;

[0085] ③Use the axial plunger loading pump 1 and the ring pressure plunger loading pump 2 to apply a pressure of 10 MPa to the sample, and check for liquid leakage; set the temperature in the thermostat 15 to 35°C, and feed back data to the data acquisition computer through the temperature sensor 11 16. Automatically adjust the temperature in the incubator 15 through the data acquisition computer 16 to ensure a constant temperature; close the valve I4, open the valve II6, and after the confining press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com