A photocatalytic system with photoresponsive switch and self-indicating, its preparation method and application

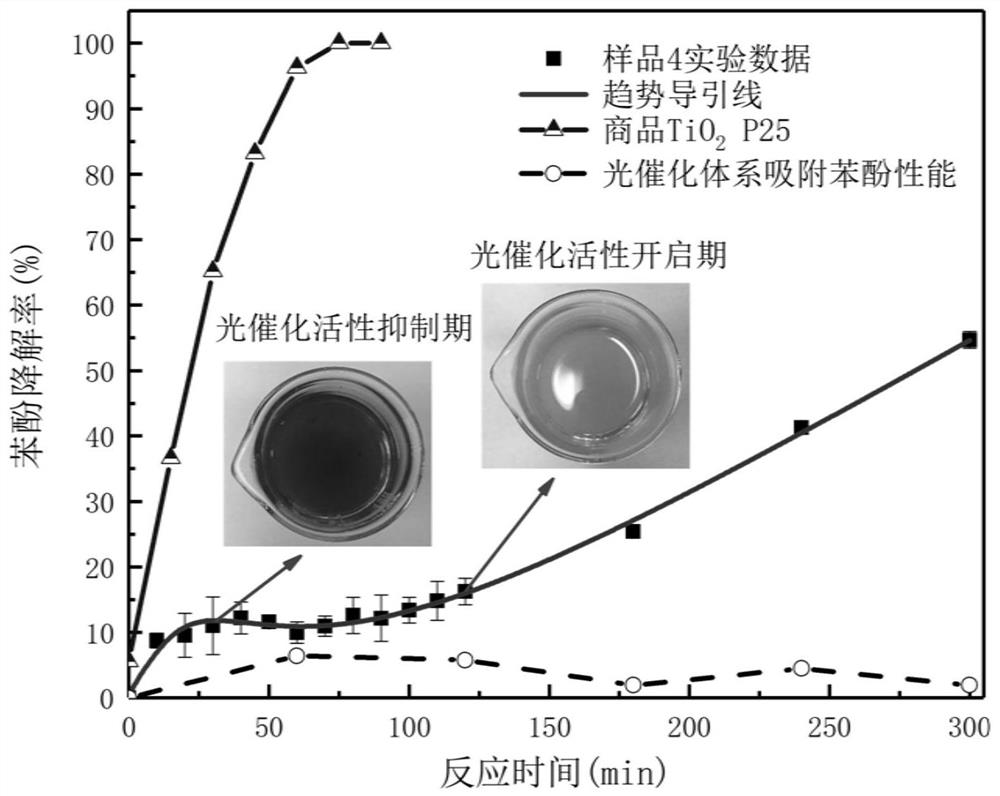

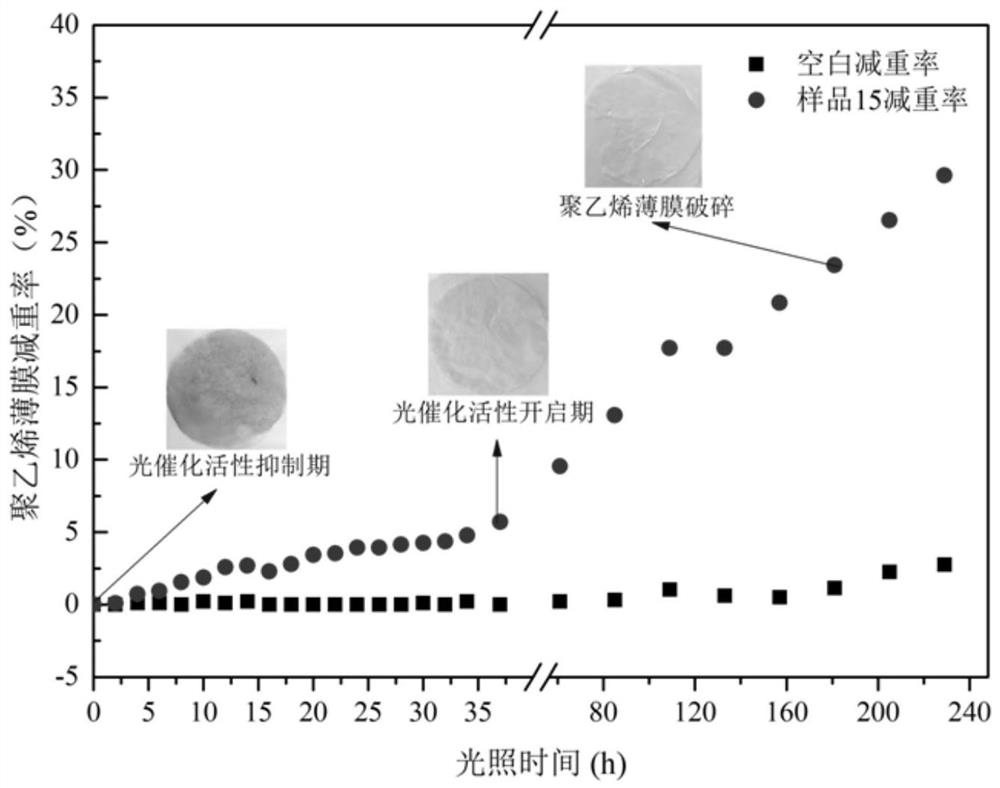

A photocatalytic and light-responsive technology, applied in the field of photocatalysis, can solve the problems of inability to achieve plastic regulation, no indication system, and no stable period for plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Step 1: Put I 2 And KI according to the molar ratio I 2 :KI=1:2, add it to the hydroxyethyl cellulose solution (molecular weight 90000) with a concentration of 0.25g / L, stir evenly, where I 2 The mass ratio to hydroxyethyl cellulose is 1:1. Add anatase TiO to the resulting mixed solution 2 Powder, TiO 2 Powder and I 2 The mass ratio is 1:2. The mixture was stirred for 24h, separated by filtration, and then dried in an oven at 35°C. Grinding I 3 - / I - Modified TiO 2 powder.

[0082] Step 2: Infiltrate 0.1g of amylose with 1mL of ethanol, then add 9mL of NaOH solution (1mol / L), heat in a boiling water bath for 10 minutes, cool to room temperature, dilute to 100mL with water to obtain a concentration of 1mg / mL amylose mixture liquid.

[0083] Step 3: Use HCl to adjust the pH value of the amylose mixture to 6.5-7.5 to prepare an amylose mixture with a pH of 6.5-7.5.

[0084] Step 4: Put the prepared I 3 - / I - Modified TiO 2 Add the powder to the amylose mixture with a pH of 6...

Embodiment 2

[0086] Same as Example 1, the difference is that I 2 And KI according to the molar ratio I 2 :KI=1:2 is added to 0.25g / L polyvinyl alcohol solution, the polyvinyl alcohol solution contains 2w% acetone, I 2 The concentration is 0.5g / L. Prepared photocatalytic system sample 2 with light response switch and self-indicating.

Embodiment 3

[0088] The same as Example 1, except that isopropanol was used instead of ethanol, and 100°C reflux was used instead of boiling water bath to prepare a photocatalytic system sample 3 with a light-responsive switch and self-indicating property.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com