Lost foam drying production line

A lost foam, production line technology, applied in the direction of surface pretreatment, coating, device for coating liquid on the surface, etc., can solve the problems of workers' physical injury, uneven drying, low drying efficiency, etc., to reduce labor The effect of time, drying uniformity and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

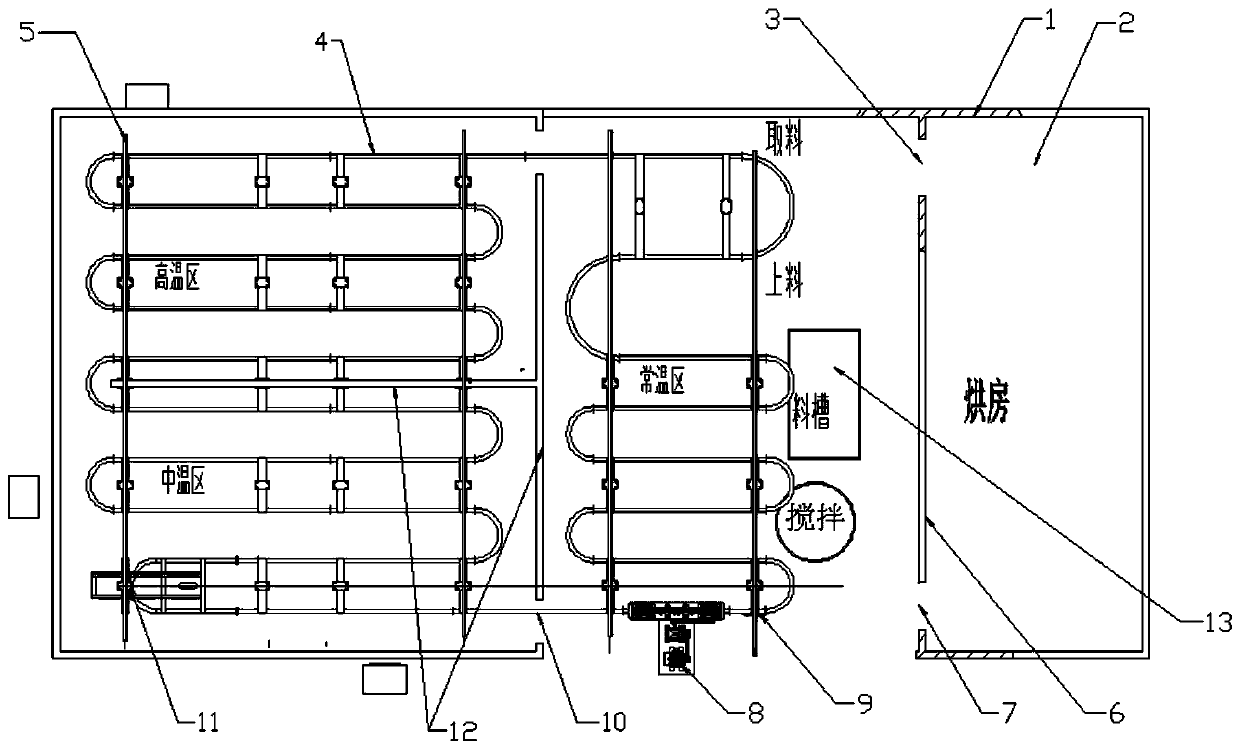

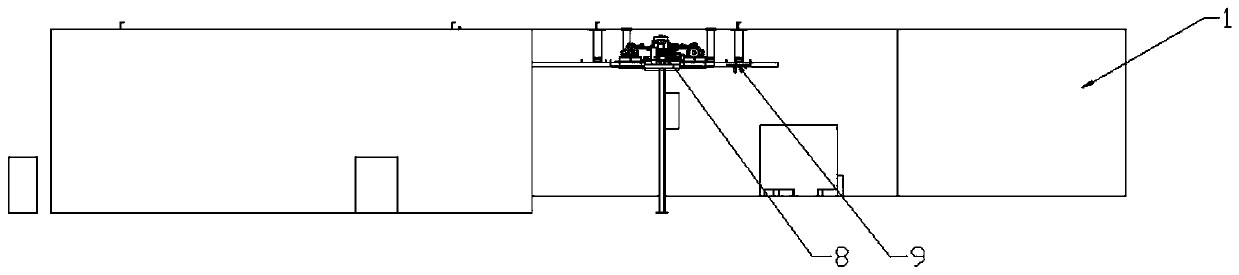

[0025] In view of the existing problems, the present invention provides a lost foam production line, including a drying room 1, the drying room 1 is divided into a normal temperature zone, a medium temperature zone and a high temperature zone, the normal temperature zone, medium temperature zone and high temperature zone The room is separated by a thermal insulation wall 12, there is a channel 10 between the thermal insulation wall 12 and the inner wall of the drying room 1, and a suspended conveyor chain 4 is provided in the drying room 1, and the suspended conveyor chain 4 passes through The channel 10 passes through the normal temperature zone, the medium temperature zone and the high temperature zone in sequence. The suspended conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com