Comb-shaped modified styrene-carboxylic acid copolymer and application thereof

A carboxylic acid copolymer and styrene technology, applied in the field of copolymers, can solve problems such as poor dispersion stability, inability to achieve cathode migration, and large range of charge neutralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

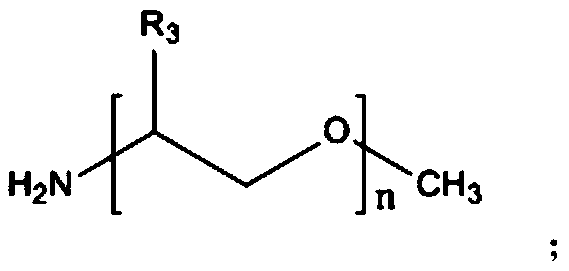

[0035] Take 100g of SMA-1000 (Mn=2000) polymer (equivalent to 0.427mol anhydride), put it into a 2000ml glass four-neck flask with stirring and condenser, add A mixture of 440g (0.22mol) of M-2005 amino-terminated polyether and 65.3g (0.64mol) of N,N-dimethylpropylenediamine, then add 5g of solid acid catalyst and deionized water; react at a temperature of 80°C for 4 After hours, the catalyst was filtered off to obtain a pale yellow transparent liquid product. Its comb unit is:

[0036]

[0037] In this example R is H or CH 3 .

Embodiment 2

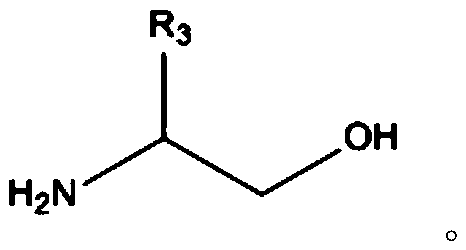

[0039] Take 100g (0.316mol acid anhydride) of Sma-2000 (Mn=3000) resin, put it into a 1000ml glass four-neck flask with stirring and condenser, add 216g (0.64mol) N,N-diethyl polyether diamine ( Mn=338), then add 4g of solid acid catalyst and deionized water; react at a temperature of 80°C for 4 hours, filter off the catalyst to obtain a light yellow transparent liquid product. Its comb unit is:

[0040]

[0041] In this example R is H or CH 3 .

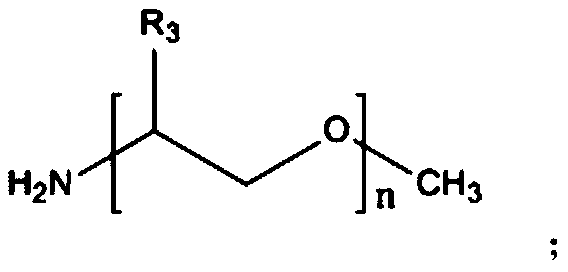

Embodiment 3

[0043] Take 100g (0.316mol anhydride) of Sma-2000 (Mn=3000) resin, put it into a 1000ml glass four-neck flask with stirring and condenser, add 108g (0.64mol) N, N-ethyl, propylhexamethylenediamine , then add 3g of solid acid catalyst and deionized water; react at a temperature of 80°C for 4 hours, filter off the catalyst to obtain a light yellow transparent liquid product. Its comb unit is:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com