A rated voltage 220kv ultra-clean ultra-smooth semi-conductive shielding material and its preparation method

A rated voltage, ultra-smooth technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of peeling, heat loss, high temperature stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

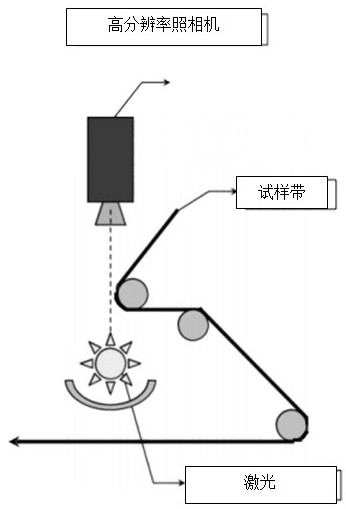

Image

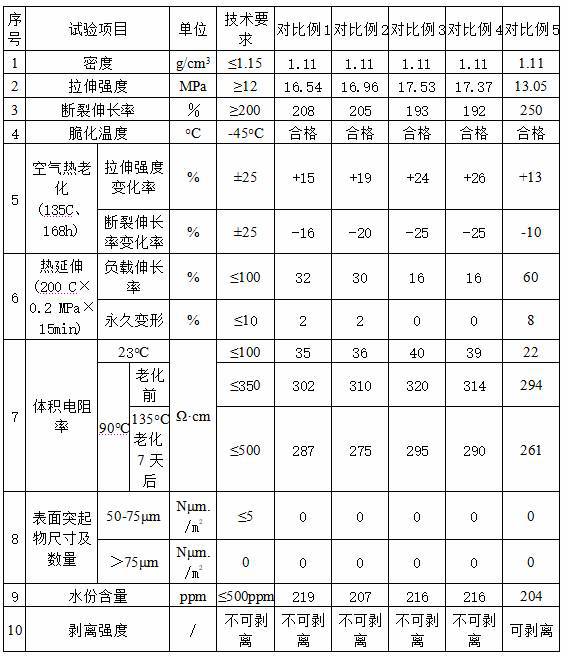

Examples

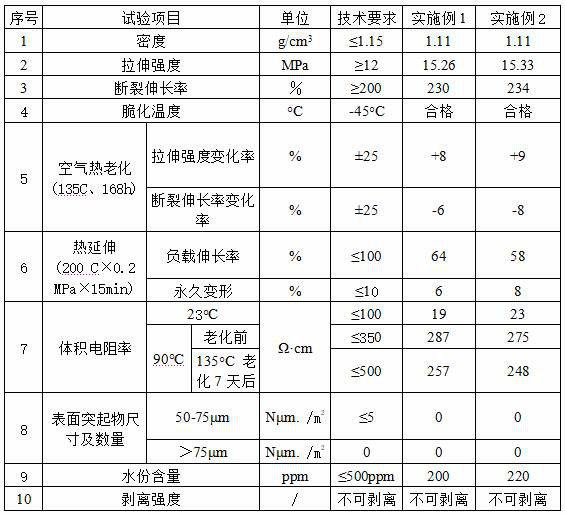

Embodiment 1

[0040]EBA, B28N230 (melt index 14g / min) 45 parts, metallocene LLDPE 18 parts, VXC72# 15 parts, Czech B-type carbon black (clean carbon black) 19 parts, silicone masterbatch 0.4 parts, cracked PE wax is 0.7 parts, 0.8 parts of ethylene bis stearamide, 0.5 parts of oleic acid amide, 0.3 parts of antioxidant 300#, 0.2 parts of antioxidant 1010#, and 0.1 part of antioxidant TBHQ. The cross-linking agent adopts BIBP, and the addition amount is 1-1.2 parts

[0041] The base resin used is EBA, B28N230, its melt index is 14g / 10min, and the number of crystal points (>100μm, each / 1200cm 2 ) <3. Its BA monomer content is 18%.

[0042] The metallocene LLDPE has a melting index of 3.2g / 10min, and the number of crystal points (>100μm, each / 1200cm 2 ) <3.

[0043] The VXC72 carbon black has a DBP absorption value of 130ml / 100g, an ash content of 0.15%, a heating loss of 0.13%, a 325 mesh residue content of 5ppm, a sulfur content of 0.1%, and a moisture content of 153ppm.

[0044] The Cz...

Embodiment 2

[0046] EBA, E1770 (melt index 12g / min) 42 parts, LDPE 2102, 20 parts, VXC72# 20 parts, Czech B-type carbon black 14 parts, cracked PE wax 2 parts, oleic acid amide 0.6 parts, ethylene bis-stearin Amide 0.9 part, antioxidant 300# 0.4 part, antioxidant 1010# 0.1 part. The cross-linking agent adopts double 25, and the addition amount is 1-1.2 parts.

[0047] The base resin used is EBA, E1770, its melt index is 14g / 10min, and the number of crystal points (>100μm, each / 1200cm 2 ) <3. Its BA monomer content is 20%.

[0048] The LDPE2102 has a melting index of 3.5g / 10min, and the number of crystal points (>100μm, one / 1200cm 2 ) <3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com