Double-network autonomous deformation gel and preparation method thereof

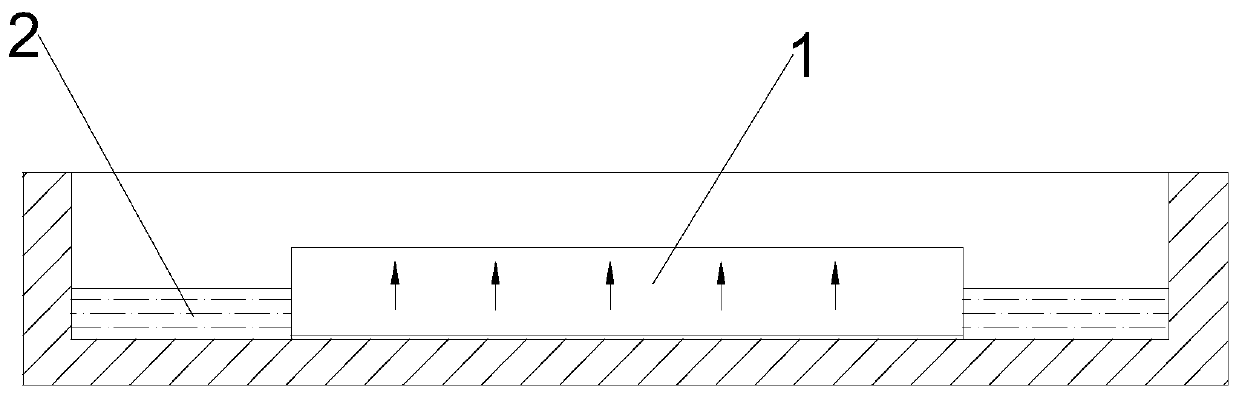

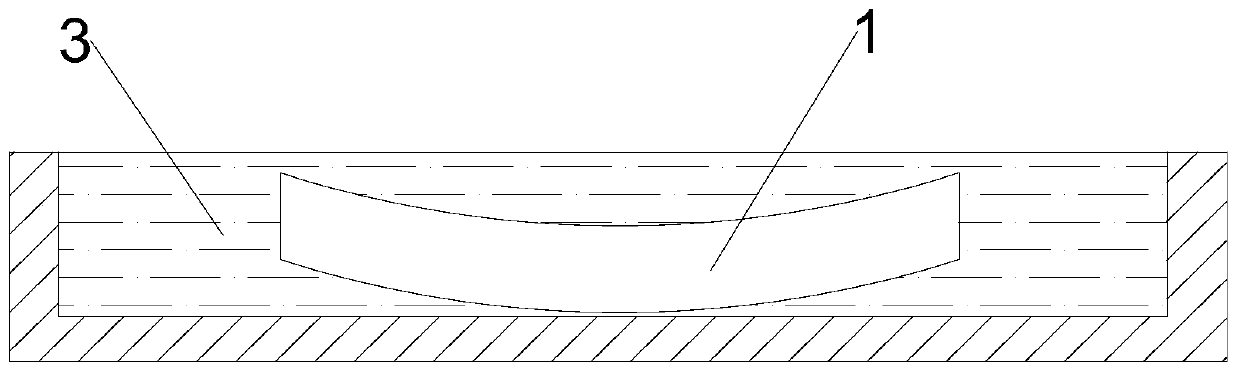

A dual-network and gel technology, applied in the field of stimuli-responsive deformation materials, can solve the problems of unsustainable response deformation behavior and uncontrollable material dynamic deformation mode, and achieve the effect of excellent autonomous deformation performance and wide application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 7.8g (29.8mmol) RuCl to a 500mL round bottom flask 3 ·3H 2 O, 9.36g (60.0mmol) 2,2'-bipyridine, 8.4g (2mmol) LiCl and 50mL dimethylformamide, heat to reflux for 9 hours, add 250mL acetone after cooling, keep at 0°C overnight, filter to get purple Filtrate and dark green solid, deionized water rinse solid three times, until the filtrate is light green, then rinse three times with 10mL ether, vacuum drying, to obtain solid product ruthenium dichlorobipyridyl;

[0037] Mix 24.0mL of 2.35mol / L n-butyllithium (LDA), 8.0mL of diisopropylamine and 30mL of tetrahydrofuran in a 500mL three-necked flask, stir for 15min, and dissolve 10g of 4,4'-dimethyl-2,2 250mL tetrahydrofuran of '-bipyridine was slowly added into the solution through a separatory funnel, and the solution turned orange. After reacting for 2 hours, add 1.7g of paraformaldehyde to the solution, and react until the color of the solution turns green. After continuing to stir for 1 hour, the reaction is stoppe...

Embodiment 2

[0049] The difference between this example and Example 1 is that in this example, the vinyl metal complex used is vinylferrocene dihexafluorophosphate, and the acrylamide monomer used is N-tert-butylpropylene Amide, the photoinitiator used is 2-hydroxyl-2-methyl-1-phenylacetone, the water-soluble initiator used is dibenzoyl peroxide, when preparing polymer network gel products, N-tert-butyl The consumption of base acrylamide is 1.17g, all the other reaction conditions and the consumption of each reactant are all identical with embodiment 1.

[0050] The autonomous deformation delay time of the pattern of this embodiment is: 250 seconds, the deformation cycle: 543 seconds, and the bending deformation range: 65%.

Embodiment 3

[0052] The difference between this example and Example 1 is that in this example, the vinyl metal complex used is dihexafluorophosphate 4'-(4-propenyloxyphenyl)-2,2':6' ,2″-terpyridine-4′-(4-methylphenyl)-2,2′:6′,2″-terpyridine ruthenium, the photoinitiator used is 2-hydroxy-2-methyl-1 -[4-(2-hydroxyethoxy) phenyl]-1-acetone, the consumption of N-isopropylacrylamide is 2.3g when the polymer network gel product, all the other reaction conditions and each reactant Consumption is all identical with embodiment 1.

[0053] The autonomous deformation delay time of the style of this embodiment is: 447 seconds, the deformation cycle: 1130 seconds, and the bending deformation amplitude is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com