Planar battery and preparation method and application thereof

A battery and planar technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the organic electrolyte cannot meet the safety and environmental friendliness, the battery construction process is not conducive to the wide application of energy storage devices, and hinders the widespread application of micro batteries. , to achieve the effect of reliable preparation method, wide application value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

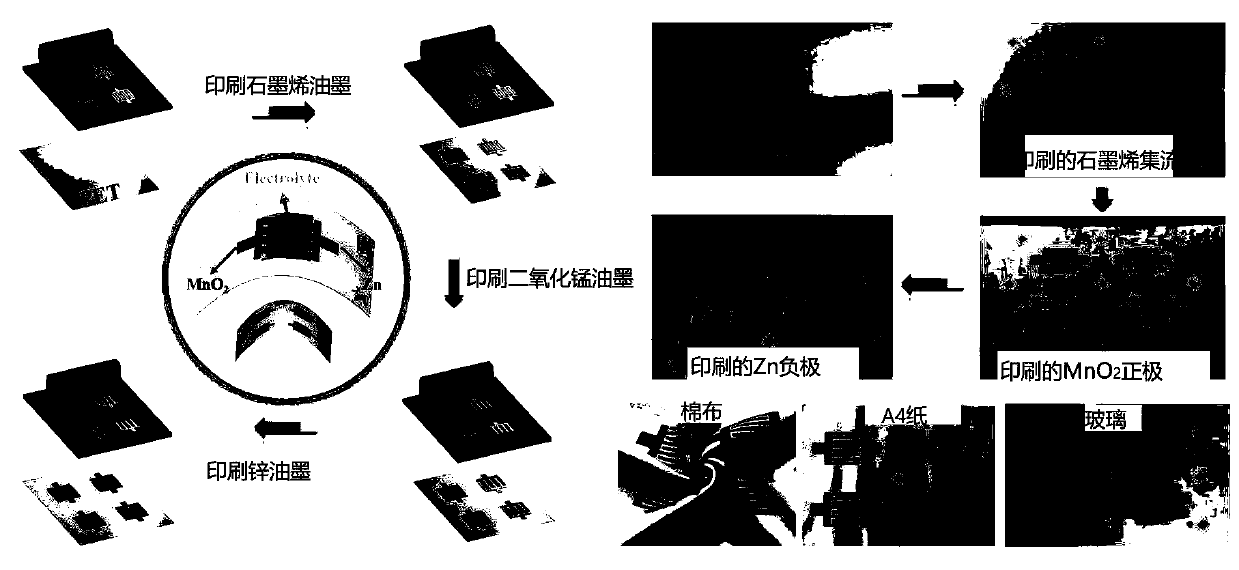

Method used

Image

Examples

Embodiment 1

[0057] Prepare graphene conductive paste: mix graphene with aromatic hydrocarbon solvent S150, ultrafine graphite, polyurethane resin, silane coupling agent KH-560, plasticizer dioctyl phthalate, and anti-settling agent in gas phase Silica, dispersant fumed silica are mixed to prepare graphene conductive paste, wherein, conductive agent (comprising graphene and ultrafine graphite, wherein the mass fraction of graphene in conductive agent is 90%), aromatic hydrocarbon solvent The ratio of mass parts between S150, polyurethane resin, silane coupling agent KH-560, plasticizer dioctyl phthalate, anti-sedimentation agent fumed silica, and dispersant fumed silica For 50:40:2:2:2:2:2.

[0058] Prepare positive electrode conductive paste: mix manganese dioxide and graphene conductive paste in a mass ratio of 1:10 to obtain a uniform positive electrode conductive paste.

[0059] Prepare negative electrode conductive paste: mix zinc powder and graphene conductive paste in a mass ratio ...

Embodiment 2

[0064] Preparation of graphene conductive paste: graphene was mixed with ethylene glycol glyceryl ether, carbon black, polyurethane resin, silane coupling agent KH-550, plasticizer dioctyl phthalate, anti-settling agent Polyolefin wax and dispersant gas phase silica are mixed to prepare graphene conductive paste, wherein, conductive agent (comprising graphene and carbon black, wherein the mass fraction of graphene in conductive agent is 95%), ethylene glycol Glycerin ether, polyurethane resin, silane coupling agent KH-550, plasticizer dioctyl phthalate, anti-sedimentation agent polyolefin wax, dispersant gas phase silica For 50:30:4:4:4:4:4.

[0065] Prepare positive electrode conductive paste: mix manganese dioxide and graphene conductive paste in a mass ratio of 1:1 to obtain a uniform positive electrode conductive paste.

[0066] Prepare negative electrode conductive paste: mix zinc powder and graphene conductive paste in a mass ratio of 2:8 to obtain uniform negative elec...

Embodiment 3

[0071] Preparation of graphene conductive paste: graphene was mixed with ethylene glycol glyceryl ether, carbon black, polyurethane resin, silane coupling agent KH-570, plasticizer dioctyl phthalate, anti-settling agent Castor oil derivatives and dispersant fumed silica are mixed to prepare the graphene conductive paste, wherein the conductive agent (comprising graphene and carbon black, wherein the mass fraction of graphene in the conductive agent is 95%), ethylene glycol Glyceryl ether, polyurethane resin, silane coupling agent KH-570, plasticizer dioctyl phthalate, anti-sedimentation agent castor oil derivatives, dispersant fumed silica The ratio is 50:30:4:3:5:4:4.

[0072] Preparation of positive electrode conductive paste: mix manganese dioxide and graphene conductive paste in a mass ratio of 10:1 to obtain a uniform positive electrode conductive paste.

[0073] Prepare negative electrode conductive paste: mix zinc powder and graphene conductive paste in a mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com