A kind of reactive dye ink for digital printing with high color fixation rate and preparation method thereof

A technology of reactive dyes and digital printing, applied in dyeing, textile and papermaking, etc., can solve the problems affecting the popularization and development of digital printing industry, and achieve the effects of excellent moisture retention, deep color, and improved color fixing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

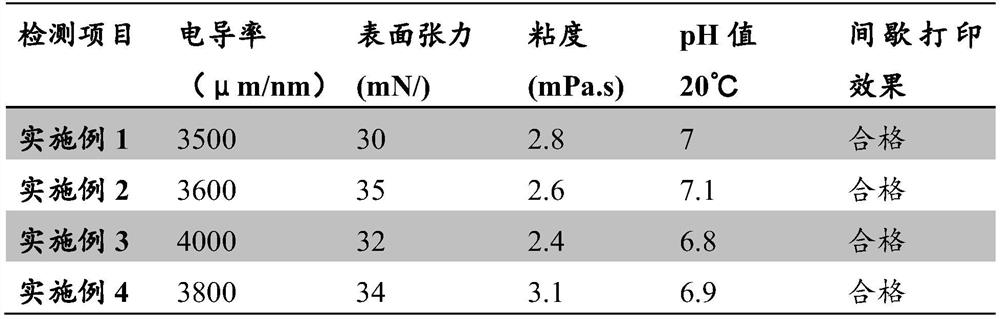

Examples

Embodiment 1

[0027] S1, the preparation of the modified styrene-acrylonitrile polymer as the polymer color-fixing and dispersing agent:

[0028] (1) Add styrene-acrylonitrile block polymer with molecular weight Mn=70000, styrene block content 25% and 1,4-dichloromethoxybutane to dichloromethane at a mass ratio of 1:2 In, reflux reaction for 6 hours, after the reaction, the reaction mixture was cooled and evaporated to dryness, washed and dried to obtain the chloromethylated product;

[0029] (2) Add the obtained chloromethylation product and 4-fold excess triethylamine into tetrahydrofuran, heat to 50°C, and react for 10 hours. After the reaction is completed, add a certain amount of distilled water, separate, wash, and dry to obtain Quaternized products;

[0030] (3) Add the quaternized product into 1M KOH solution, heat to 50°C, stir for 10 hours, then filter and wash until the filtrate is neutral, and obtain a polymer color-fixing dispersant after drying.

[0031] S2, a reactive dye i...

Embodiment 2

[0034] S1, the preparation of the modified styrene-acrylonitrile polymer as the polymer color-fixing and dispersing agent:

[0035](1) Add styrene-acrylonitrile block polymer with molecular weight Mn=72000, styrene block content 32% and 1,4-dichloromethoxybutane to dichloromethane at a mass ratio of 1:2 , reflux reaction for 10 hours, after the reaction, the reaction mixture was cooled and evaporated to dryness, washed and dried to obtain chloromethylated product;

[0036] (2) Add the obtained chloromethylated product and 4-fold excess triethylamine into tetrahydrofuran, heat to 80° C., and react for 5 hours. After the reaction is completed, add a certain amount of distilled water, separate, wash, and dry to obtain Quaternized products;

[0037] (3) Add the quaternized product to 1M KOH solution, heat to 30-50°C, stir for 5-10 hours, then filter and wash until the filtrate is neutral, and obtain a polymer color-fixing dispersant after drying.

[0038] S2, a kind of reactive ...

Embodiment 3

[0041] S1, the preparation of the modified styrene-acrylonitrile polymer as the polymer color-fixing and dispersing agent:

[0042] (1) Add styrene-acrylonitrile block polymer with molecular weight Mn=70000, styrene block content of 28% and 1,4-dichloromethoxybutane to dichloromethane at a mass ratio of 1:2 , reflux reaction for 10 hours, after the reaction, the reaction mixture was cooled and evaporated to dryness, washed and dried to obtain chloromethylated product;

[0043] (2) Add the obtained chloromethylation product and 4-fold excess triethylamine into tetrahydrofuran, heat to 50°C, and react for 10 hours. After the reaction is completed, add a certain amount of distilled water, separate, wash, and dry to obtain Quaternized products;

[0044] (3) Add the quaternized product into 1M KOH solution, heat to 50°C, stir for 10 hours, then filter and wash until the filtrate is neutral, and obtain a polymer color-fixing dispersant after drying.

[0045] S2, a kind of reactive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com