Calibration device for quickly positioning collimating lens and calibrating beam pointing

A technology of collimating lenses and calibrating beams, which is applied in the field of laser radar optical system debugging, can solve the problems of not intuitive and convenient operation, inability to cooperate with joint debugging, and limited precision, etc., and achieve intuitive debugging process, light weight and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

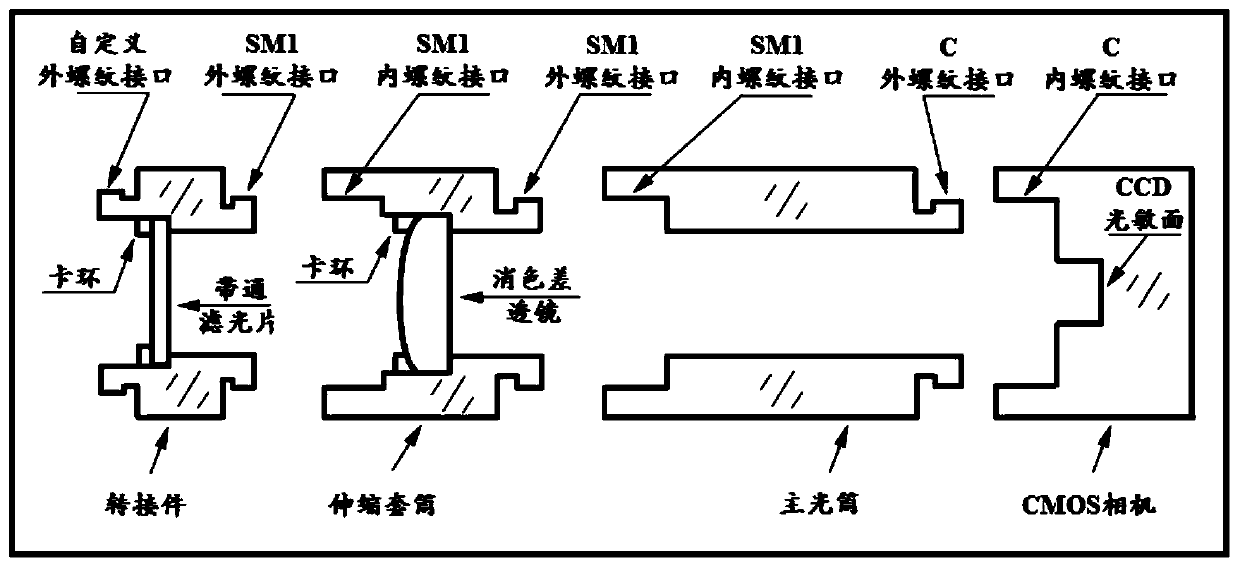

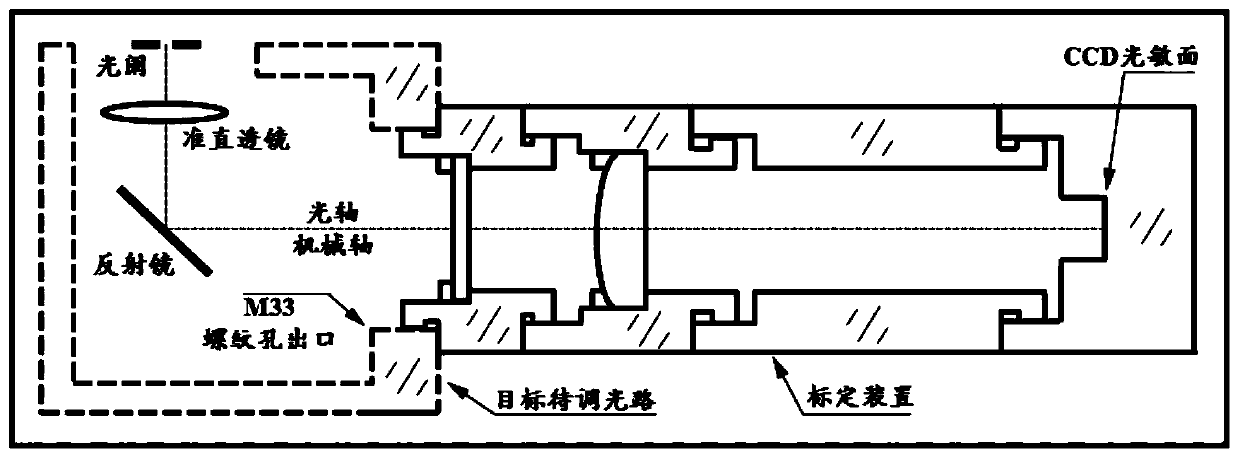

[0031] A calibration device for quickly positioning the collimating lens and calibrating beam pointing provided by the embodiment, including a bandpass filter, an adapter, a telescopic sleeve, an achromatic lens, a main light tube, and a CMOS camera;

[0032] The bandpass filter is used to extract the optical signal in the target spectral band;

[0033] The adapter is used to fix the bandpass filter and quickly access the target optical path to be adjusted;

[0034] The telescopic sleeve is used to fix the achromatic lens;

[0035] The achromatic lens is used for converging the incoming quasi-parallel light signal on the photosensitive surface of the area array CCD of the CMOS camera;

[0036] The main optical tube is used to combine with the telescopic sleeve to ensure that the focal plane of the achromatic lens can coincide with the photosensitive surface of the area array CCD in the CMOS camera;

[0037] The CMOS camera is used for collecting and displaying in real time t...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, the difference is: the central wavelength of the band-pass filter is changed to 355nm; the achromatic lens is selected from the American Thorlabs company ACA254-150-UV model product, and the corresponding focal length of the spectral segment near 355nm is 150mm. For this reason, the present invention can calibrate the position of the collimating lens and the pointing of the light beam working in the ultraviolet band around 355nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com