Radioactive source flip system servo control method

A technology of servo control and radioactive source, applied in the control system, observer control, motor control and other directions, can solve the problems of danger, can not meet the irradiation requirements, etc., to achieve strong overload capacity, good low frequency characteristics, and serious lag phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for servo control of a radioactive source flip-chip system, the method comprising the following steps:

[0064] (1) Parameter identification based on the least square method;

[0065] The principle of least square fitting can be used to fit the parameters of the quadratic equation, and the servo system is used to measure the different input of The angular position output of , the amplitude ratio of the input and output is obtained, that is , substitute into the corresponding and The value of , and then fit, first get value, obtained by calculating , , The value of is brought back to the original form to get the object properties . However, due to inaccurate measurements, the first obtained , , There may be negative values among them, which requires multiple sets of data to be fitted to obtain a set of normal value;

[0066] (2) Obtain the motor parameters of the servo system;

[0067] (3) Establishment of the linearly extended state...

Embodiment 2

[0070] According to the servo control method of the radioactive source flip-chip system described in Embodiment 1, the specific process of obtaining the quadratic polynomial in the step (1) is as follows:

[0071] First of all, it is necessary to model the system model through the experimental method. For the parameter model of the servo motor, the mechanism model of the controlled object should be simplified. The characteristics of the object are now set as:

[0072] (1)

[0073] Will Substitute into the object characteristics to get the amplitude-frequency characteristics of the servo system,

[0074] (2)

[0075] Assume , the above formula can be changed into

[0076] (3)

[0077] reset , , so the above formula becomes

[0078] (4)

[0079] The above formula is a quadratic polynomial.

Embodiment 3

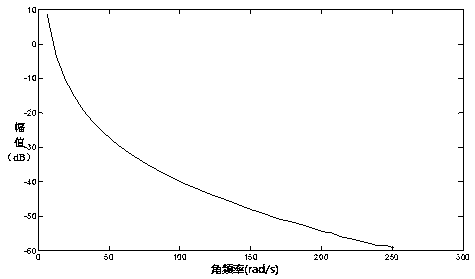

[0081] According to the servo control method of the radioactive source flip-chip system described in Embodiment 1 or 2, the specific process of the step (2) is: measure the angular position output for different inputs, and measure the amplitude of the input and output as figure 1 As shown, after calculation, the result of finally solving the transfer function of the servo system is:

[0082] (5)

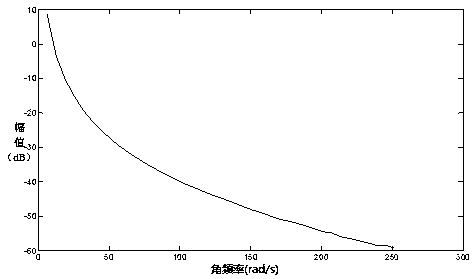

[0083] The amplitude ratio of the transfer function is compared with the measured amplitude ratio such as figure 2 shown;

[0084] It has been verified that the curve fitting error between the amplitude ratio of the transfer function and the measured amplitude ratio is relatively small, and this result can be used as the transfer function of the controlled object as the basis for subsequent design;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com