Epoxy butyl rubber, preparation method and applications thereof

A technology of epoxy butyl and butyl rubber, which is applied in the chemical industry, can solve the problems of difficulty in epoxidation and low unsaturation of butyl rubber, and achieve controllable epoxidation degree, good compatibility and air tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

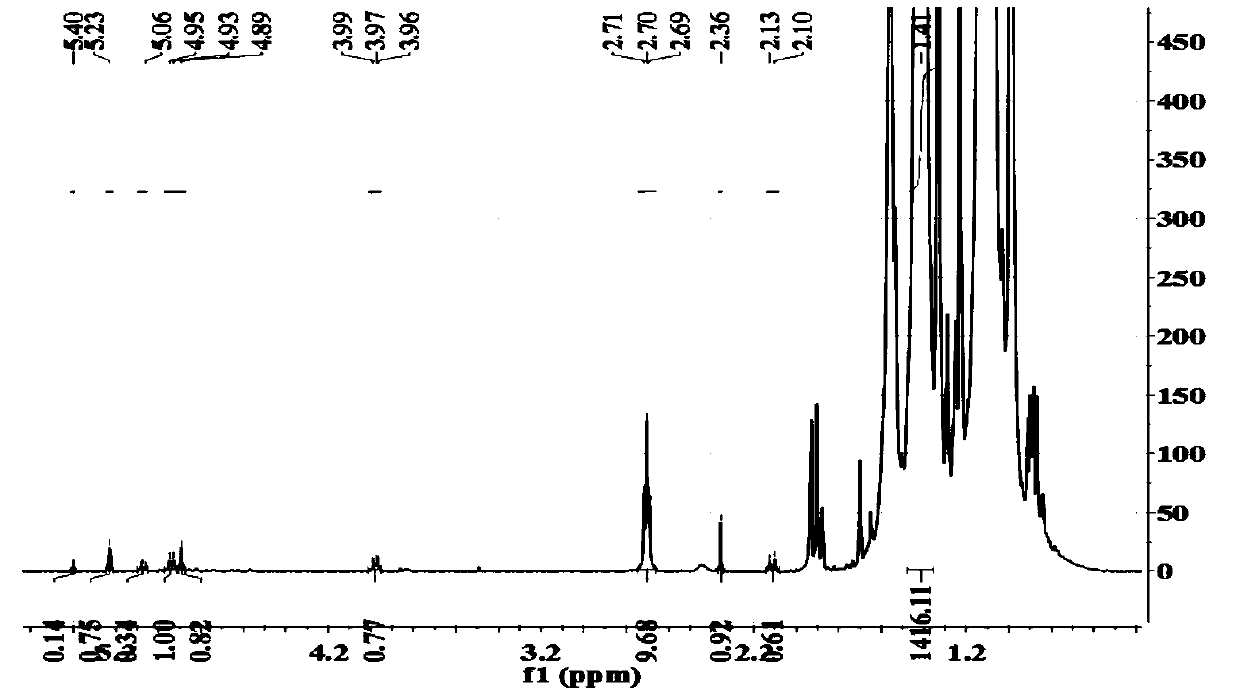

Embodiment 1

[0034] Weigh 10 g of butyl rubber (weight average molecular weight: 550,000, degree of unsaturation: 1.89%), cut into pieces and place in a four-neck flask, add 100 ml of n-hexane to dissolve. After the colloidal particles are completely dissolved, the four-necked flask is at room temperature (23~25 ℃), and slowly adding 31.5ml mass concentration is 2% epoxidation reagent m-chloroperoxybenzoic acid-toluene solution (the The mol ratio of double bond and m-chloroperoxybenzoic acid is 1:1.3), start to react, after reacting for 2h, neutralize with the sodium hydroxide solution of 1% with mass concentration, adjust the pH value of glue to 7~10, Wash the glue solution with 200ml distilled water for 3 to 4 times, and solidify the glue solution into a glue block. The prepared epoxybutyl rubber was detected by nuclear magnetic resonance method, the degree of double bond epoxidation was 82.0%, and the degree of ring opening was 6.69%.

Embodiment 2

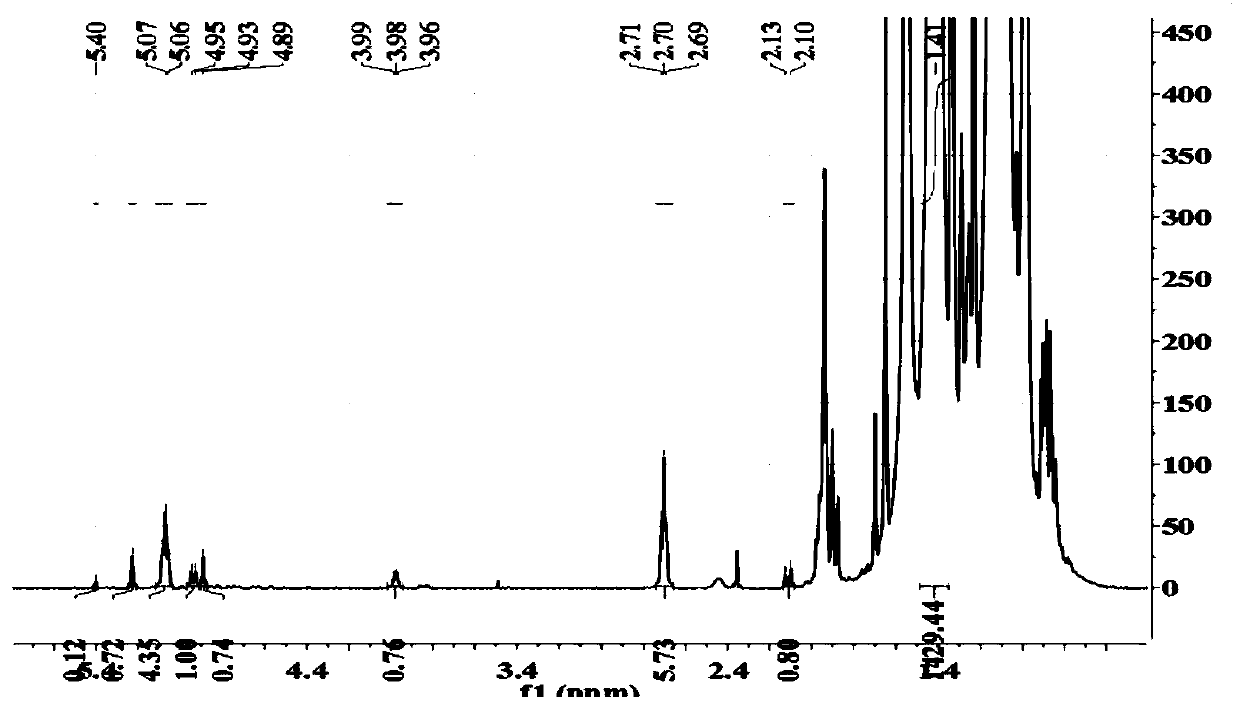

[0036] Weigh 10 g of butyl rubber (weight-average molecular weight: 400,000, degree of unsaturation: 1.89%), cut it into pieces and place it in a four-necked flask, and add 100 ml of n-hexane to dissolve it. After the colloidal particles were completely dissolved, the four-necked flask was placed in a constant temperature water bath with an initial reaction temperature of 4°C, and slowly adding 21.5ml of mass concentration was 2% epoxidation reagent m-chloroperoxybenzoic acid-toluene solution (butyl The mol ratio of the double bond in the rubber to m-chloroperoxybenzoic acid is 1:0.8), close the thermostat, and after continuing to react for 2h, neutralize with a mass concentration of 1% sodium hydroxide solution, and adjust the pH value of the glue to 7-10, wash the glue solution with 200ml distilled water for 3-4 times, and solidify the glue solution into a glue block. Detected by nuclear magnetic resonance method, the degree of double bond epoxidation of the prepared epoxidi...

Embodiment 3

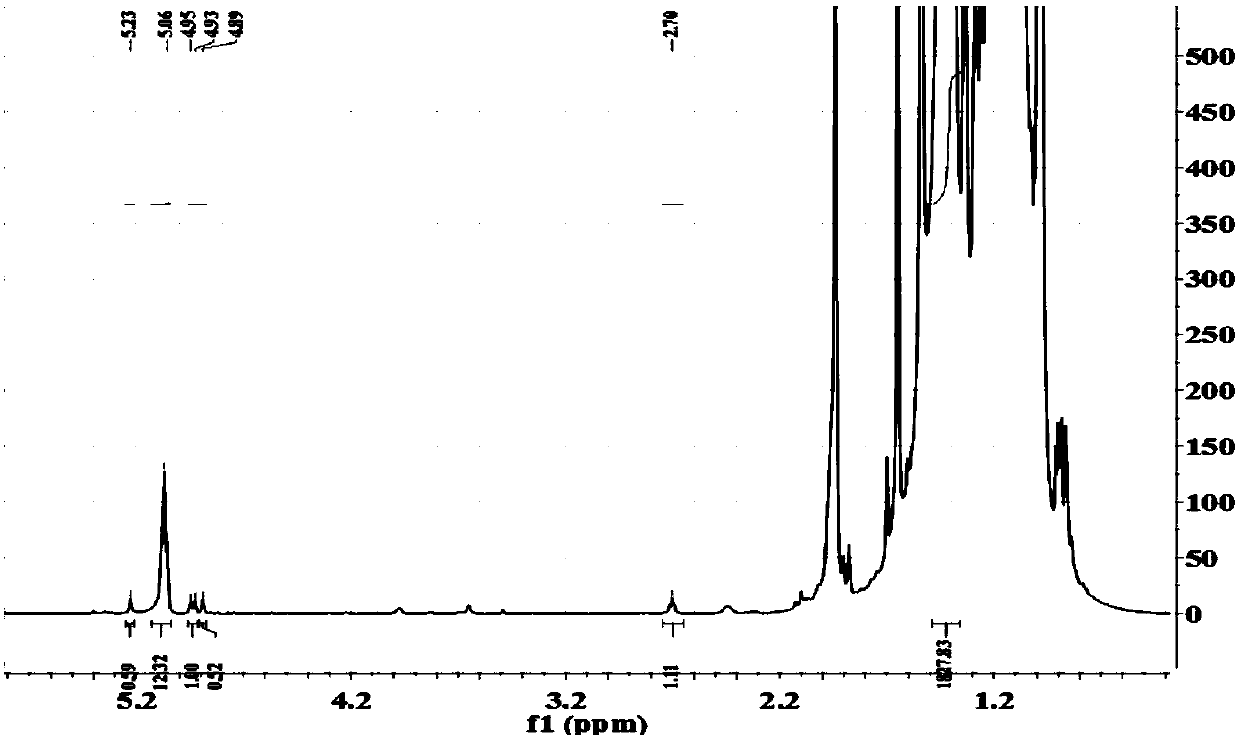

[0038] Weigh 10 g of butyl rubber (weight-average molecular weight: 650,000, degree of unsaturation: 1.70%), cut it into pieces and place it in a four-necked flask, and add 100 ml of n-hexane to dissolve it. After the colloidal particles are completely dissolved, place the four-neck flask in a constant temperature water bath at 40°C, add 0.4ml polyethylenediene monolaurate to keep it stable for 2h, slowly add 0.09ml of formic acid with a mass concentration of 88%, and 0.57ml with a mass concentration of 88% formic acid. 30% hydrogen peroxide starts to react (formic acid:hydrogen peroxide molar ratio 0.8:1), after 1.5 hours of reaction, neutralize with 1% sodium hydroxide solution, adjust the pH value of the glue to 7-10 , Wash the glue solution with 150ml distilled water for 3 to 4 times, and solidify the glue solution into a glue block. Detected by nuclear magnetic resonance, the double bond epoxidation degree of the prepared epoxybutyl rubber is 7.4%, and the ring opening de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com