Polylactic acid modified shape memory intelligent deformation material and preparation method thereof

A deformation material and polylactic acid technology, applied in the field of deformation material preparation, can solve the problems of difficult film formation and poor impact resistance, achieve high mechanical strength and rapid deformation ability, improve processing efficiency, and break through mechanical strength and deformation. The effect of characteristics that are difficult to improve together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) Preparation of polylactic acid modified material slurry:

[0031] The composition of polylactic acid modified material slurry: polylactic acid is used as the main material of shape memory intelligent deformation, granular polyetheretherketone is used as the modified material for performance enhancement, and dichloromethane is used as the solvent. Weigh the polylactic acid powder and polyether ether ketone powder in proportion, wherein the mass percentage of polylactic acid powder is 65wt.%-95wt.%, preferably 70wt.%-90wt.%, and the mass percentage of polyetheretherketone powder is 5wt.%-35wt. %, preferably 10wt.%-30wt.%, the mass percentage of evenly mixed powder and dichloromethane solvent is 1:5.

[0032] Ingredients: Weigh the polylactic acid powder and polyetheretherketone powder according to the ingredient ratio in a, and ball mill the weighed powder in a ball mill with a rotation speed of 100r / min-140r / min for 5h-6h to make it evenly mixed . The uniformly mixe...

Embodiment 1

[0037] Polylactic acid sample preparation:

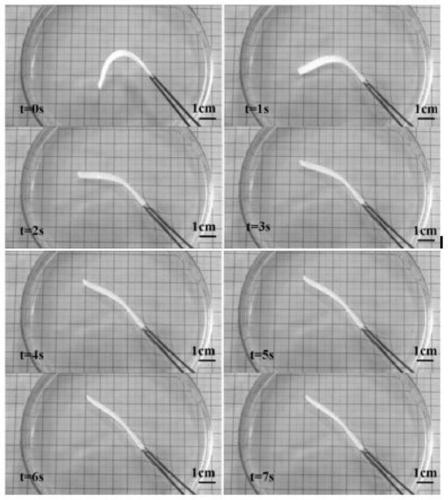

[0038] Weigh 5 g of polylactic acid powder respectively, and ball mill and mix the weighed powder in a formal ball mill with a rotating speed of 100 r / min for 6 hours to make them evenly mixed. The uniformly mixed powder was mixed with 25 g of dichloromethane solvent, and stirred with a magnetic stirrer at room temperature for 3 hours to obtain a shape memory polymer suspension with relatively high viscosity. Put the prepared shape-memory polymer suspension into the syringe barrel, remove the air bubbles in the syringe, inject 3ml of the polymer suspension into the mold, scrape it flat, and place it at 25°C for 0.5h to form a film. Repeat this process 5 times to prepare a rectangular sheet with a size of 50mm×10mm×1mm, see figure 1 shown.

Embodiment 2

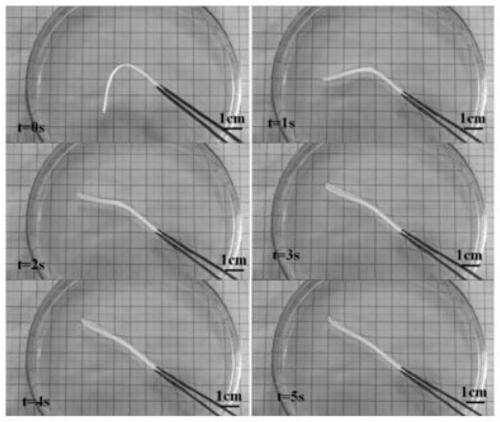

[0040] 90% polylactic acid 10% polyether ether ketone modified polylactic acid sample preparation:

[0041]Weigh 4.5g of polylactic acid powder and 0.5g of polyether ether ketone powder respectively, and ball mill and mix the weighed powders in a formal ball mill with a rotation speed of 100r / min for 6h to make them evenly mixed. The uniformly mixed powder was mixed with 25 g of dichloromethane solvent, and stirred with a magnetic stirrer at room temperature for 3 hours to obtain a shape memory polymer suspension with relatively high viscosity. Put the prepared shape-memory polymer suspension into the syringe barrel, remove the air bubbles in the syringe, inject 5ml of the polymer suspension into the mold, scrape it flat, and place it at 25°C for 0.5h to form a film. Repeat this process 5 times to prepare a rectangular sheet with a size of 50mm×10mm×1mm, see figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com