Super-hydrophilic self-cleaning coating material composition and preparation method thereof, and super-hydrophilic self-cleaning glass and preparation method thereof

A self-cleaning, super-hydrophilic technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of coating surface blooming, poor hydrophilic effect, complicated preparation, etc. Achieve low shrinkage, excellent superhydrophilicity, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a kind of preparation method of superhydrophilic self-cleaning coating composition, comprises the following steps:

[0041] (1) Preparation of modified nano-silica sol: under acidic conditions, water is added dropwise to the mixture of tetraethyl orthosilicate, alcohol and silane coupling agent to obtain modified nano-silica sol;

[0042] (2) Preparation of super-hydrophilic self-cleaning coating: the prepared modified nano-silica sol was mixed with anatase-type nano-titanium dioxide sol and water to obtain a super-hydrophilic self-cleaning coating.

[0043] According to the present invention, in step (1), based on the total weight of the modified nano-silica sol, the amount of tetraethyl orthosilicate is 15-25wt%, for example, can be 15wt%, 16wt% , 17wt%, 18wt%, 19wt%, 20wt%, 21wt%, 22wt%, 23wt%, 24wt%, 25wt% and any value in the range formed by any two of these point values; the amount of alcohol 50-60wt%, such as 50wt%, 51wt%, 52w...

Embodiment 1

[0070] 1. Preparation of modified nano-silica sol

[0071] Mix 40.00g TEOS, 130.00g absolute ethanol, and 8.49g silane coupling agent evenly, adjust the pH to 2-3 with hydrochloric acid, and add 59.81g deionized water dropwise at a rate of 0.1mL / s while stirring , and react at a constant temperature of 55° C. for 6 hours to obtain a uniform and transparent modified nano-silica sol.

[0072] 2. Preparation of superhydrophilic self-cleaning coating composition

[0073] Mix 25g of anatase-type nano-titanium dioxide sol with a mass fraction of 0.5% with the above-mentioned 1g of modified silica sol, and dilute with water to prepare a superhydrophilic nanometer self-cleaning coating.

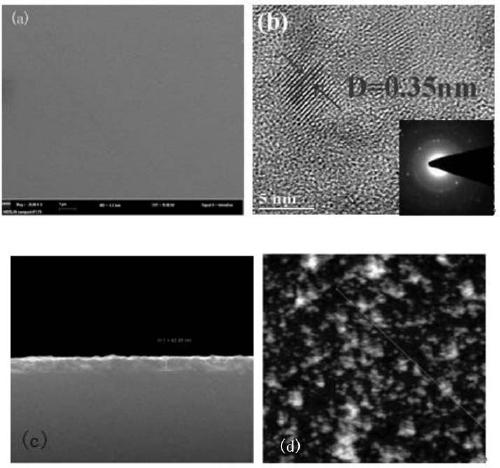

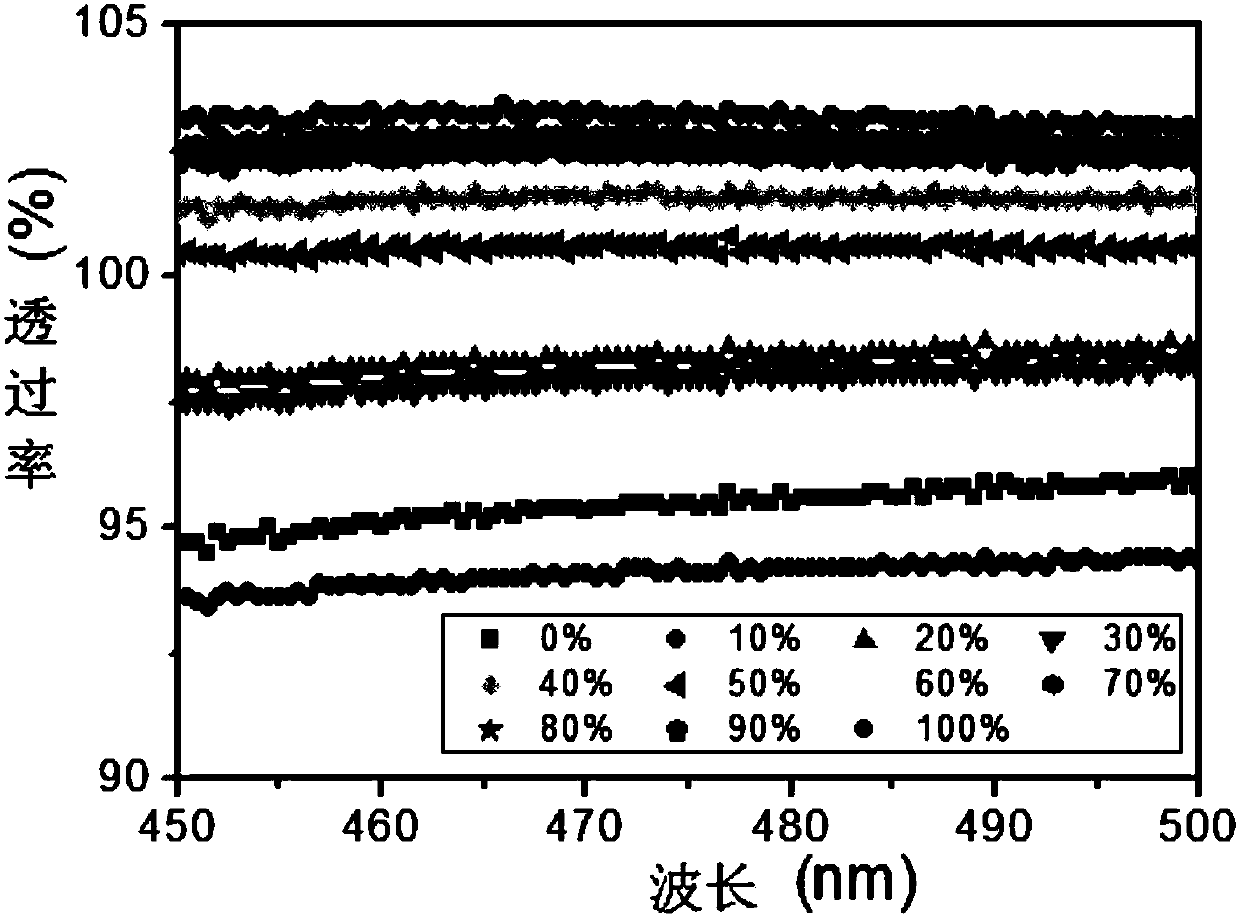

[0074] 3. Testing the adhesion, microscopic morphology and photocatalytic degradation performance of superhydrophilic nano self-cleaning coating composition coating

[0075] (1) Coating adhesion test

[0076] The cross-hatch method was used to test the adhesion of the prepared superhydrophilic nan...

Embodiment 2

[0089] 1. Preparation of modified nano-silica sol

[0090] Mix 40.00g TEOS, 111.91g absolute ethanol, and 7.59g silane coupling agent evenly, adjust the pH to 2-3 with hydrochloric acid, and drop 53.45g deionized water at a rate of 0.1mL / s under stirring Add, and react at a constant temperature of 55° C. for 6 hours to prepare a uniform and transparent modified nano-silica sol.

[0091] 2. Preparation of superhydrophilic self-cleaning coating composition

[0092] Mix 15g of anatase-type nano-titanium dioxide sol with a mass fraction of 0.5% with the above-mentioned 1g of modified silica sol, and dilute with water to prepare a super-hydrophilic nanometer self-cleaning coating.

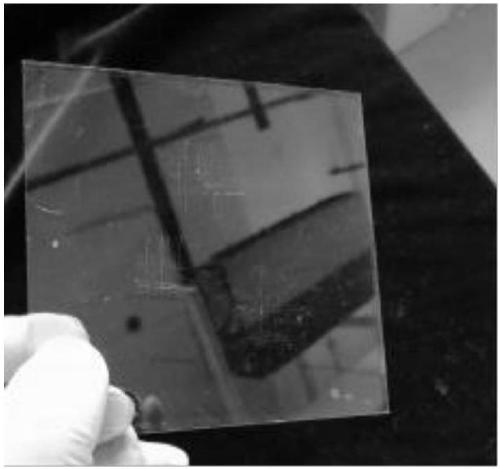

[0093] 3. Preparation of superhydrophilic self-cleaning glass

[0094] Use a dropper to absorb an appropriate amount of super-hydrophilic nano-self-cleaning coating sample and drop it on the edge of the high-density sponge, repeat it several times, so that the sample is fully infiltrated on the edge o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com