Single-load damage test method for material in high-pressure hydrogen-doped natural gas environment

A natural gas and environmental technology, which is applied in the direction of material separation, material analysis, and application of stable tension/pressure to test the strength of materials, etc., can solve problems such as hidden safety hazards, high time costs, and complex equipment structures, so as to improve reliability and Safety, meet the test temperature requirements, avoid the effect of the servo test mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

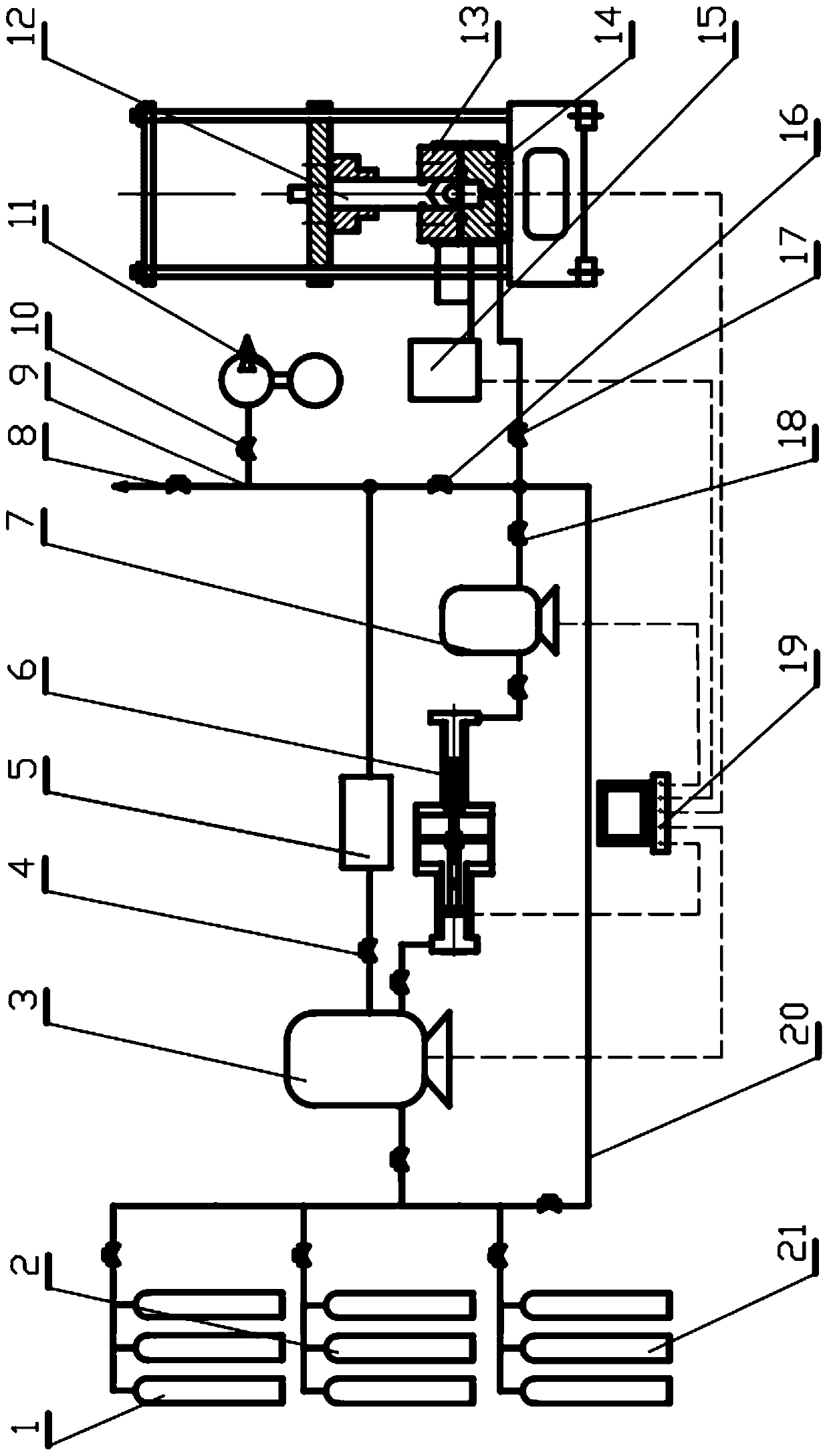

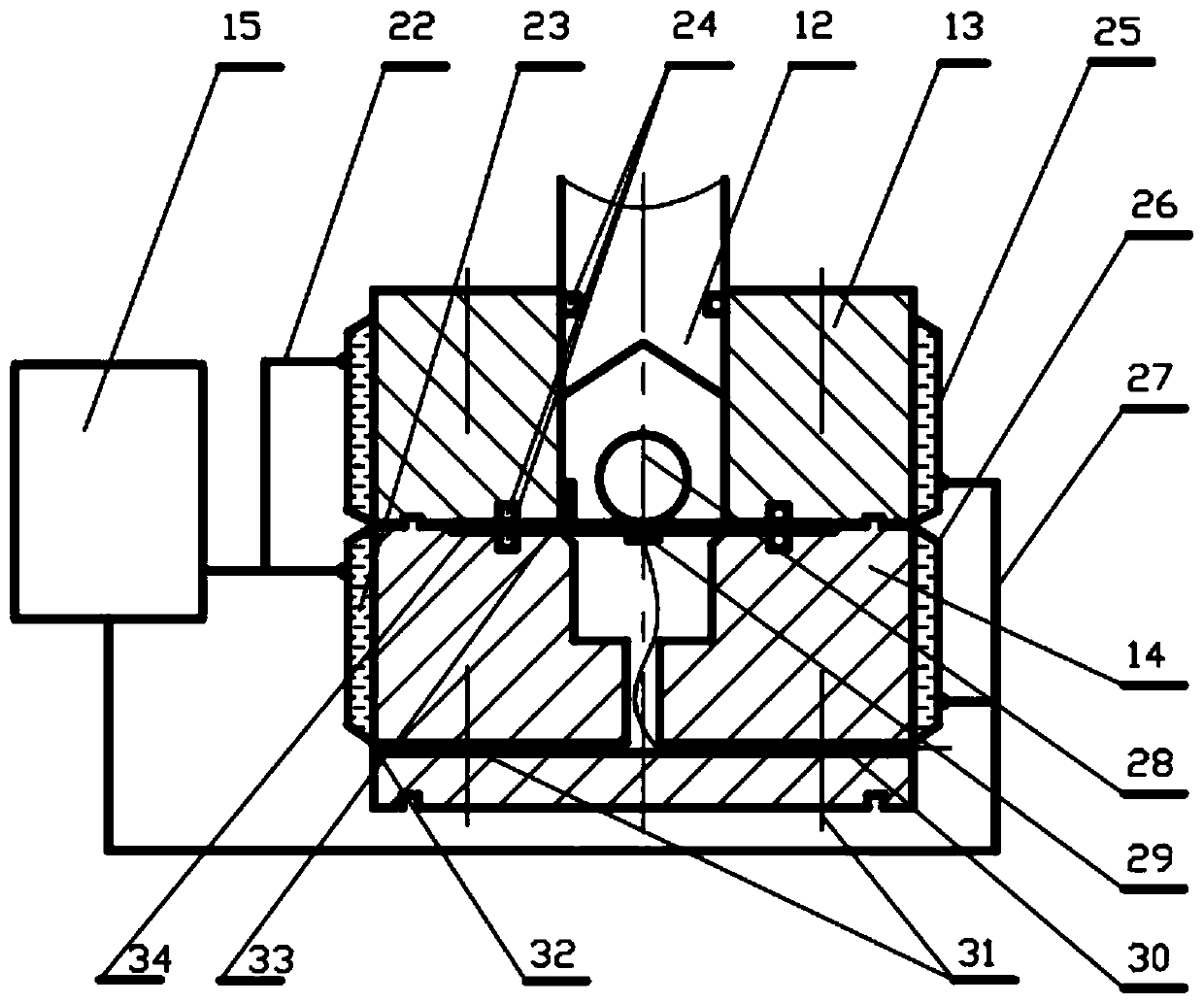

[0041] The hydrogen-doped natural gas environmental material performance damage evaluation device used in this example is as follows: figure 1 and figure 2 As shown, it includes natural gas cylinder set 1 for supplying natural gas for testing, hydrogen cylinder set 2 for supplying hydrogen for testing, and argon cylinder set 21 for replacement. The gas cylinder set 1 and hydrogen cylinder set 2 are connected to the low-pressure The buffer tank 3 and the outlet of the low-pressure buffer tank 3 are divided into two paths: one path is connected to the pneumatic booster pump 6, and then the high-pressure buffer tank 7, and the exhaust port of the high-pressure buffer tank 7 is connected to the lower environment on the lower environmental box 14 Casing inlet (exhaust) gas port 32; The chromatographic analyzer 5 can be used to measure the content of each component in the hydrogen / natural gas mixed gas, and then adjust the content ratio of each component in the mixed gas to realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com