Soil improvement method

A soil improvement and soil technology, applied in land preparation methods, botanical equipment and methods, plant protection, etc., can solve problems such as the inability of rapid fermentation of organic materials, the inability of cultivated land to be flooded, and the inability to maintain an anaerobic environment. The effect of shortening time, accelerating fermentation speed, and high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

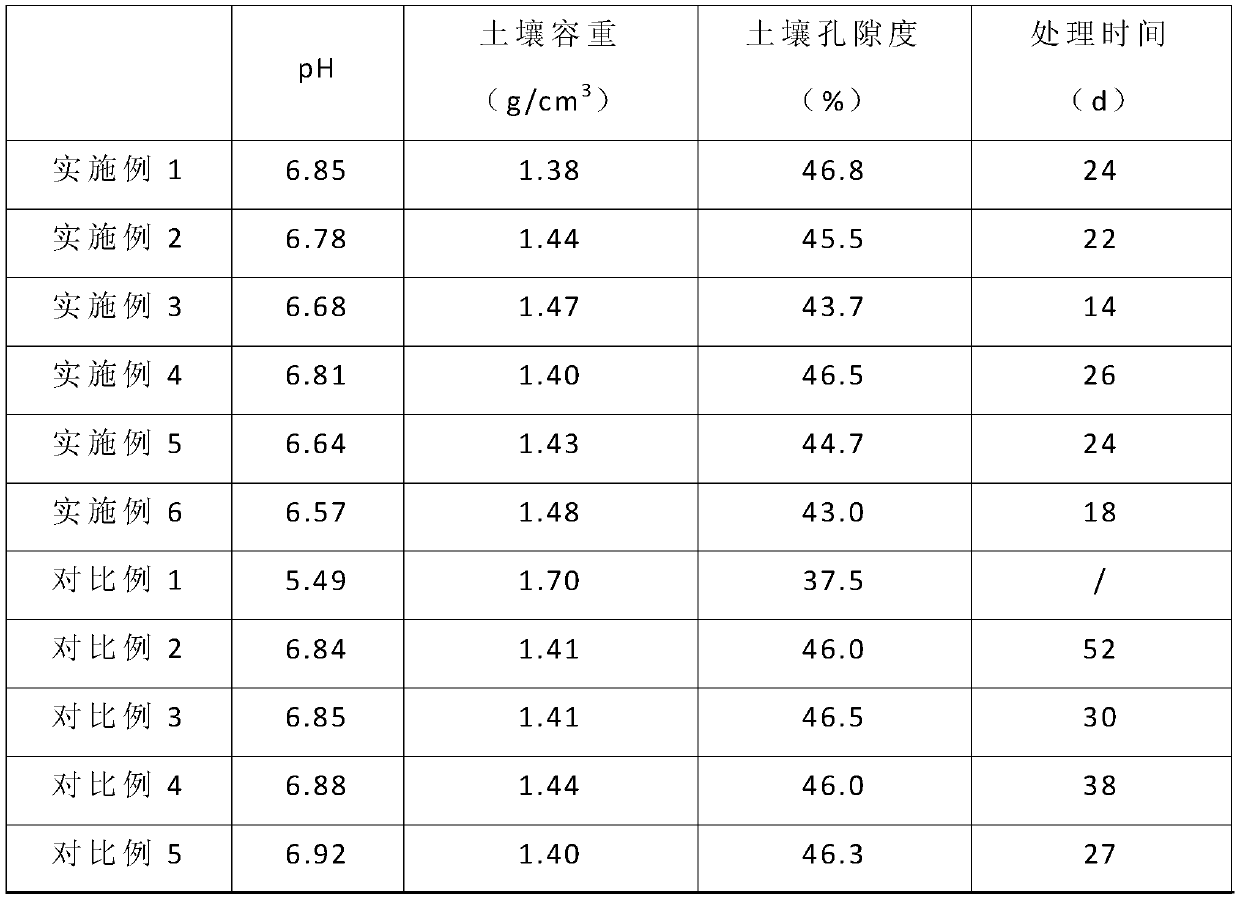

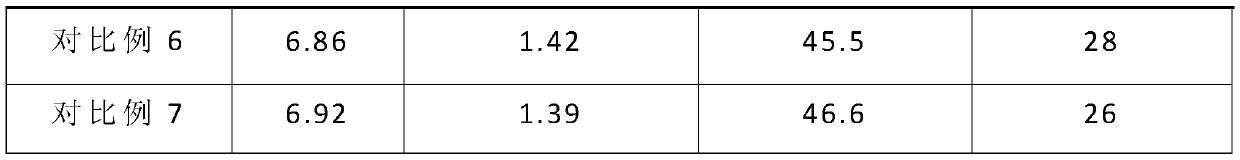

Examples

Embodiment 1

[0024] A soil improvement method, comprising the steps of:

[0025] (1) Soil preparation: Deep plow the soil with a powder ridge machine, and the depth of plowing is 40-50cm;

[0026] (2) Applying organic materials: the organic materials include the following components in parts by weight: 30 parts of rice straw, 20 parts of decomposed pig manure, 10 parts of decomposed horse manure, 20 parts of waste vegetable leaves, 20 parts of tea seed cake, silkworm 10 parts of sand, 8 parts of sugarcane filter mud, 5 parts of bran and 15 parts of alfalfa, the organic material is collected and dried and pulverized into particles below 2mm, collected by weight and applied to the soil layer below the depth of 15cm and Mix with the soil, the application rate is 1000kg / mu, level the soil after application, and irrigate the soil until the soil moisture content reaches 80% of the maximum field water holding capacity;

[0027] (3) Apply microbial inoculum: the microbial inoculum includes the fo...

Embodiment 2

[0030] (1) Soil preparation: Deep plow the soil with a powder ridge machine, and the depth of plowing is 40-50cm;

[0031] (2) Applying organic materials: the organic materials include the following components in parts by weight: 40 parts of rice straw, 30 parts of decomposed pig manure, 20 parts of decomposed horse manure, 20 parts of waste vegetable leaves, 10 parts of tea seed cake, silkworm 30 parts of sand, 4 parts of sugarcane filter mud, 15 parts of bran and 10 parts of alfalfa, the organic material is collected and dried and pulverized into particles below 2 mm, collected by weight, applied to the soil layer below the depth of 15 cm and Mix with the soil, the application rate is 750kg / mu, level the soil after application, and irrigate the soil until the soil moisture content reaches 80% of the maximum field water holding capacity;

[0032] (3) Apply microbial inoculum: the microbial inoculum includes the following components in parts by volume: 30 parts of colloidal ba...

Embodiment 3

[0035](1) Soil preparation: Deep plow the soil with a powder ridge machine, and the depth of plowing is 40-50cm;

[0036] (2) Applying organic materials: the organic materials include the following components in parts by weight: 50 parts of rice straw, 20 parts of decomposed pig manure, 30 parts of decomposed horse manure, 30 parts of waste vegetable leaves, 30 parts of tea seed cake, silkworm 20 parts of sand, 6 parts of sugarcane filter mud, 10 parts of bran and 5 parts of alfalfa, the organic material is collected and dried and pulverized into particles below 2mm, collected by weight and applied to the soil layer below the depth of 15cm and Mix with the soil, the application rate is 500kg / mu, level the soil after application, and irrigate the soil until the soil moisture content reaches 80% of the maximum field water holding capacity;

[0037] (3) Apply microbial inoculum: the microbial inoculum includes the following components in parts by volume: 40 parts of colloidal bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com