Essence with suspended microbeads and preparation method of essence

A technology of essence and microbeads, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as weak residue, lack of emollient protection, and increased risk of skin irritation, achieving good stability and repairing Tightens the skin and slows down the effects of photoaging damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

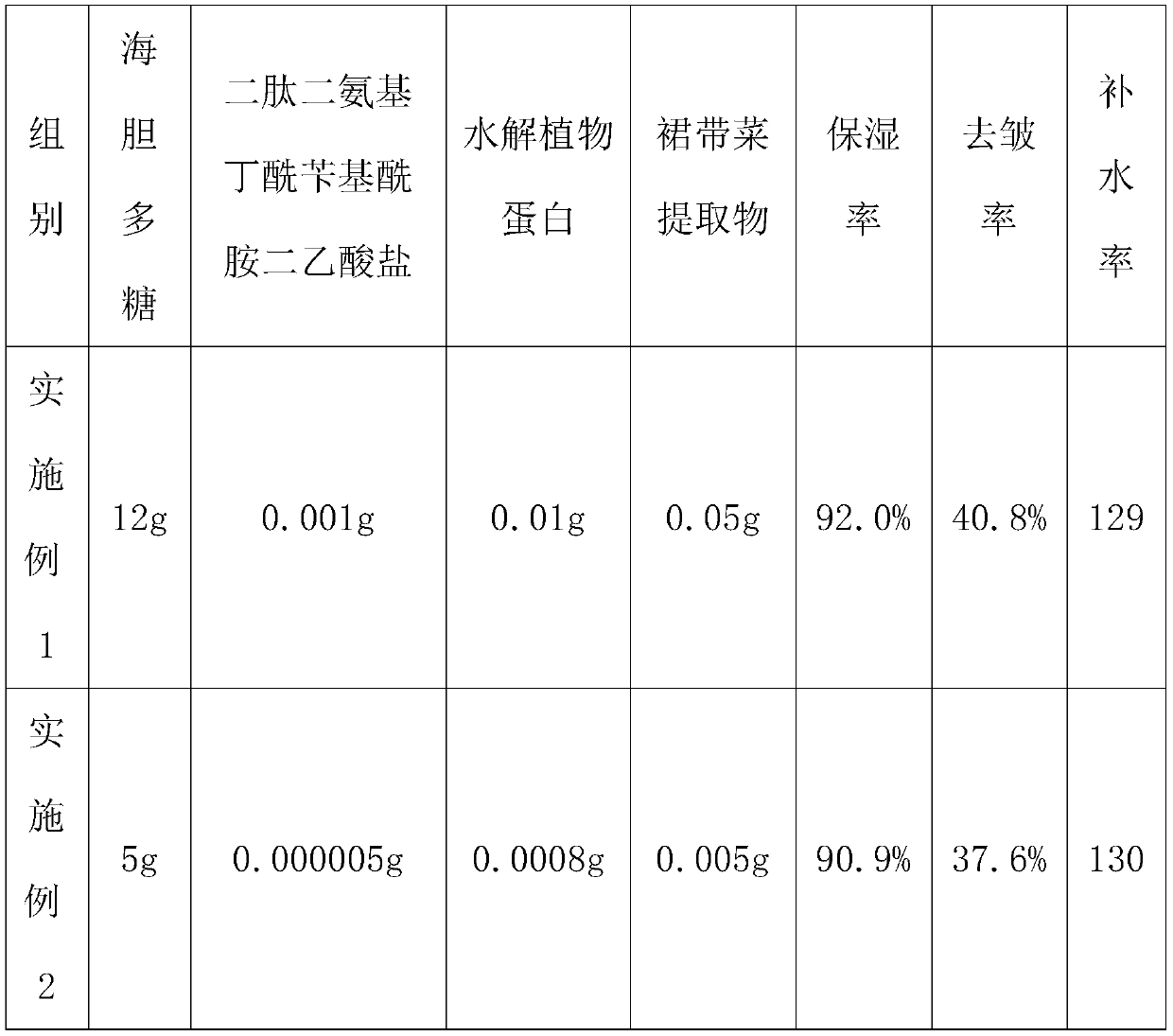

Embodiment 1

[0053] This embodiment provides an essence with suspended microbeads, which is prepared by the following steps:

[0054] Divide 88g of solvent water into eleven parts, named as the first part to the eleventh part, respectively, and divide the 2g of glycerin in the first part into five parts, named as the first part to the fifth part of glycerin; Dihydrate, 0.02g of NaOH as a pH regulator, and 3g of ethanol are put into the first container and mixed to prepare the C-phase material;

[0055] Pre-dissolve 10 g of pentaerythritol tetraester, 10 g of the second glycerol, 8 g of butanediol, and 0.1 g of dipotassium glycyrrhizinate at a temperature of 76° C. to prepare a D-phase material;

[0056] Mix the third water and NaOH 0.03g into the second container and mix to obtain the E phase material;

[0057] The fourth water, 0.5g of sodium hyaluronate, 0.1g of dipotassium glycyrrhizinate and 0.1g of sodium polyglutamate are mixed in the third container to obtain the F phase material; ...

Embodiment 2

[0067] This embodiment provides an essence with suspended microbeads, which is prepared by the following steps:

[0068] Divide 60g of solvent water into ten parts and name them as the first water part to the tenth water part respectively; 0.02 g of NaOH and 3 g of ethanol as a pH regulator are put into the first container and mixed to prepare the C-phase material;

[0069] Mix 5 g of pentaerythritol tetraester, 5 g of the second glycerin portion, 1 g of butanediol, and 0.03 g of dipotassium glycyrrhizinate, and pre-dissolve them at a temperature of 72° C. to prepare a D-phase material;

[0070] Mix the third water and NaOH 0.03g into the second container and mix to obtain the E phase material;

[0071] The fourth water, 0.01g of sodium hyaluronate, 0.03g of dipotassium glycyrrhizinate and 0.01g of sodium polyglutamate are mixed in the third container to obtain the F phase material;

[0072] Mix 0.01g of PPG-26-butanol-26, 0.01g of PEG-40 hydrogenated castor oil and 0.005g o...

Embodiment 3

[0081] This embodiment provides an essence with suspended microbeads, which is prepared by the following steps:

[0082] Divide 75g of solvent water into ten parts, named as the first water part to the tenth water part, the first part of glycerin 2g is divided into five parts, named as the first glycerin part to the fifth part of glycerin; the second water part 0.04 g of NaOH and 2 g of ethanol as a pH regulator are put into the first container and mixed to prepare the C-phase material;

[0083] Mix 7g of pentaerythritol tetraester, 7g of the second glycerol, 3g of butanediol, and 0.07g of dipotassium glycyrrhizinate and pre-dissolve at a temperature of 75°C to prepare the D-phase material;

[0084] Mix the third water and NaOH 0.03g into the second container and mix to obtain the E phase material;

[0085] The fourth water, 0.07g of sodium hyaluronate, 0.07g of dipotassium glycyrrhizinate and 0.06g of sodium polyglutamate are mixed in the third container to obtain the F phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com