Preparation method of sulfur dioxide adsorbent used for flue gas treatment

A technology of sulfur dioxide and fumed silica, which is applied in the direction of chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems such as the ability to adsorb sulfur dioxide that have not been mentioned, and achieve the reduction of conditional guarantee consumption, high selective adsorption, and adsorption The effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

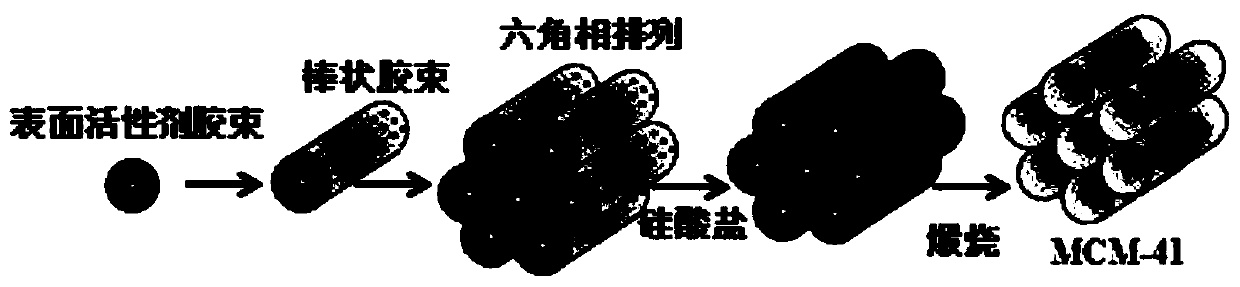

[0031] Specific examples: in a beaker, mix 2.4g29% of ammonium hydroxide (NH 4 OH) solution and 21.2g25% cetrimonium chloride solution (CH 3 (CH 2 ) 15 N(Cl)(CH 3 ) 3 ), 3.0g tetramethylammonium hydroxide pentahydrate ((CH 3 ) 4 N(OH)·5H 2 O), 18.9g10% tetramethylammonium silicate ((CH 3 ) 4 N(OH)·2SiO 2 ) solution, and 4.5g fumed silica (SiO 2 ) to form a reaction gel, use a magnetic stirrer to stir the gel for 30 minutes, then put it into a hydrothermal reaction kettle, keep it in a reaction oven at 80°C for 24 hours, and take it out after 24 hours of natural cooling. After taking it out, open the hot water reaction kettle, and adjust the pH value to 8.0 by concentrated sulfuric acid. Then carry out the hydrothermal reaction process at 80° C. for 24 hours. The process of adjusting the pH and continuing the hydrothermal reaction is a total of 3 times. The conditions of each hydrothermal reaction are 80°C and 24 hours. Air dry for 48 hours. The powder calcination...

Embodiment example 1

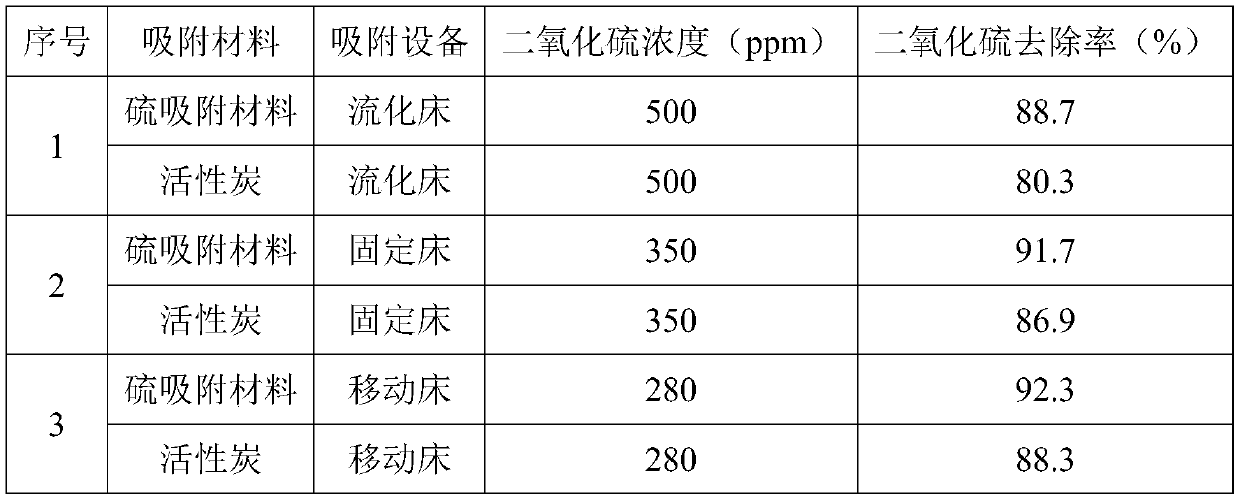

[0035] Adsorption method of sulfur dioxide in flue gas by adsorbent: Carry out in fluidized bed, make flue gas fully contact with adsorbent, flue gas flow rate 2.0L / min, sulfur dioxide concentration in flue gas 500ppm, adsorption temperature can be 350°C. The contact pressure is 0.15MPa, the adsorption cycle is 24 hours, the sulfur dioxide removal rate is 88.7%, and the sulfur adsorption capacity is 5.5%.

Embodiment example 2

[0037] The method of adsorption of sulfur dioxide in the flue gas by the adsorbent: carry out in a fixed bed, make the flue gas fully contact with the adsorbent, the flue gas flow rate is 5.0L / min, the sulfur dioxide concentration in the flue gas is 350ppm, and the adsorption temperature can be 400°C. The contact pressure is 0.18MPa, the adsorption cycle is 12 hours, the sulfur dioxide removal rate is 91.7%, and the sulfur adsorption capacity is 5.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com