Hydrothermal synthesis method of Fe-MFI molecular sieve

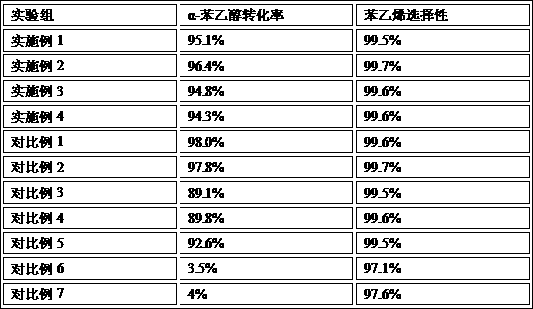

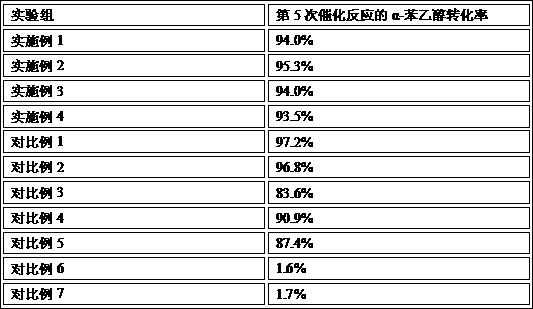

A hydrothermal synthesis and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve high production costs, poor catalytic activity and stability, and difficulty in meeting actual use requirements, etc. problem, to achieve the effect of improved catalytic conversion rate and excellent catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of hydrothermal synthesis method of Fe-MFI molecular sieve, comprises following preparation steps:

[0029] (1) Fe(NO 3 ) 3 9H 2 O, tetraethyl orthosilicate, template and deionized water in proportion to Fe(NO 3 ) 3 9H 2 O: tetraethyl orthosilicate: template agent: deionized water = 0.4g:40g:30g:100mL, mix well, keep the temperature at 50°C for 10h, then raise the temperature to 60°C for 1h, and obtain the molecular sieve precursor gel; the template agent is the solute Mass percentage composition is the tetrapropyl ammonium hydroxide aqueous solution of 25wt%;

[0030] (2) configure the crystallization auxiliary agent, the crystallization auxiliary agent is CeO 2 -RuO 2 Composite oxide powder, powder passed through a 2000-mesh sieve;

[0031] (3) After mixing the molecular sieve precursor gel and the crystallization auxiliary agent, put it in a sealed container and raise the temperature to 160-180°C, keep it warm for 3 days, then cool it to room temperatu...

Embodiment 2

[0038] A kind of hydrothermal synthesis method of Fe-MFI molecular sieve, comprises following preparation steps:

[0039] (1) Fe(NO 3 ) 3 9H 2 O, tetraethyl orthosilicate, template and deionized water in proportion to Fe(NO 3 ) 3 9H 2 O: tetraethyl orthosilicate: template agent: deionized water = 0.8g:42g:32g:100mL, mix well, keep the temperature at 50°C for 10h, then raise the temperature to 70°C for 1h, and obtain the molecular sieve precursor gel; the template agent is the solute Mass percentage composition is the tetrapropyl ammonium hydroxide aqueous solution of 25wt%;

[0040](2) configure the crystallization auxiliary agent, the crystallization auxiliary agent is CeO 2 -RuO 2 Composite oxide powder, powder passed through a 2000-mesh sieve;

[0041] (3) After mixing the molecular sieve precursor gel and the crystallization auxiliary agent, put it in a sealed container and raise the temperature to 160-180°C, keep it warm for 3 days, then cool it to room temperatur...

Embodiment 3

[0048] A kind of hydrothermal synthesis method of Fe-MFI molecular sieve, comprises following preparation steps:

[0049] (1) Fe(NO 3 ) 3 9H 2 O, tetraethyl orthosilicate, template and deionized water in proportion to Fe(NO 3 ) 3 9H 2 O: tetraethyl orthosilicate: template agent: deionized water = 1.6g:44g:34g:100mL, mix well, keep the temperature at 50°C for 10h, then raise the temperature to 80°C for 1h, and obtain the molecular sieve precursor gel; the template agent is the solute Mass percentage composition is the tetrapropylammonium bromide aqueous solution of 25wt%;

[0050] (2) configure the crystallization auxiliary agent, the crystallization auxiliary agent is CeO 2 -RuO 2 Composite oxide powder, powder passed through a 2000-mesh sieve;

[0051] (3) After mixing the molecular sieve precursor gel and the crystallization auxiliary agent, put it in a sealed container and raise the temperature to 160-180°C, keep it warm for 3 days, then cool it to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com