Damping emulsion, preparation method thereof, low-VOC, low-odor and high-flame-retardance water-based damping coating and preparation method of coating

A damping coating, high flame-retardant technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of oil-based paints such as high VOC, polluting the environment, flammable and explosive, and achieve good flame-retardant and fire-resistant performance, easy to dry, The effect of excellent damping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

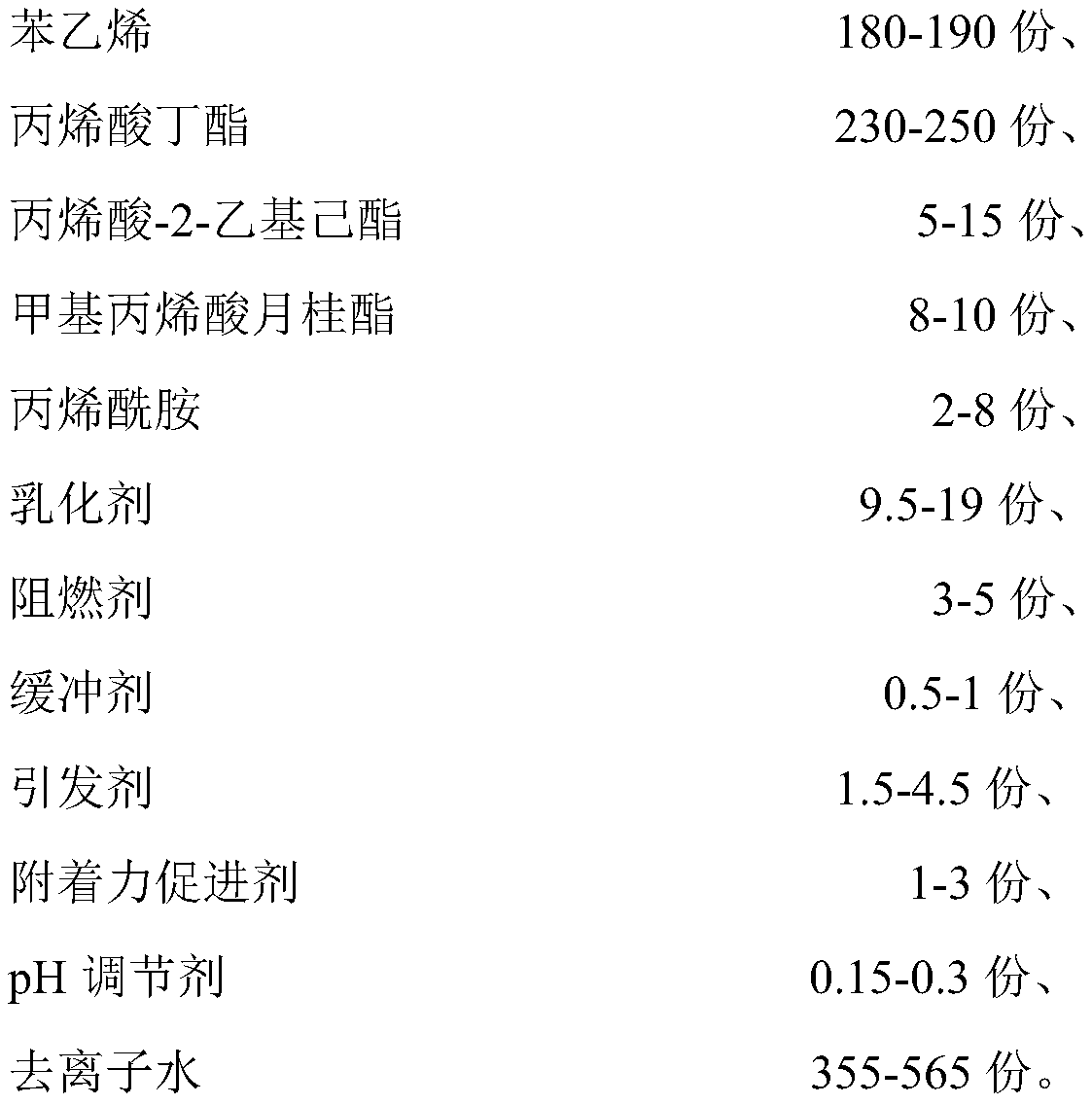

[0036] A damping emulsion of the present invention, which comprises the following components in parts by weight:

[0037]

[0038] Among them, the emulsifier is at least one of sodium lauryl sulfate, OP-10, and CO436, the adhesion promoter is vinyl triethoxy silane, and the pH regulator is 2-amino-2-methyl-1 -Propanol, the buffer is sodium bicarbonate, the initiator is sodium persulfate, and the flame retardant is tribromophenyl maleimide.

[0039] The preparation method of the damping emulsion of this embodiment includes the following steps:

[0040] S1. Combine 185 parts of styrene, 240 parts of butyl acrylate, 10 parts of 2-ethylhexyl acrylate, 10 parts of lauryl methacrylate, 6 parts of acrylamide, 4 parts of flame retardant, 0.5 parts of buffer and 8 parts Part of the emulsifier (containing sodium lauryl sulfate and OP-10) was dissolved in deionized water and added to the pre-emulsification kettle, stirred and mixed for 30 minutes to obtain a pre-emulsified liquid;

[0041] S2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com